Our PLA 3D Printing Services

Discover the future of sustainable manufacturing with PLA 3D Printing—the eco-friendly solution powered by biodegradable polymer technology. Whether you need rapid prototypes, custom parts, or large-scale production, our expertise in Fused Deposition Modeling (FDM) and high-precision printing delivers cost-effective, high-quality results tailored to your industry. From medical devices to aerospace components, we turn ideas into reality with speed, accuracy, and a commitment to the planet.

What Is PLA 3D Printing?

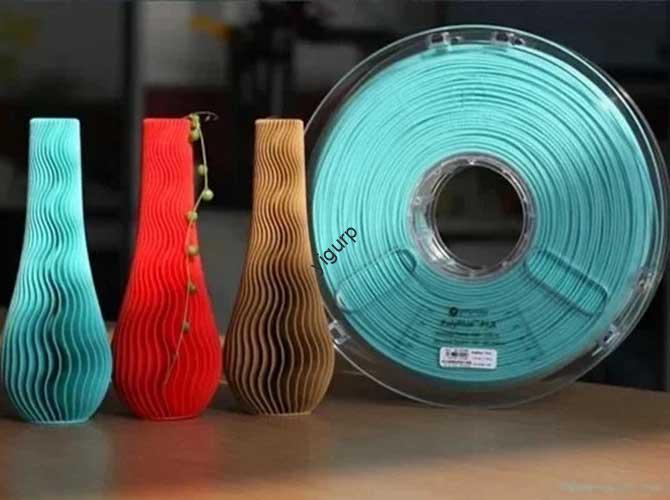

PLA 3D Printing is an additive manufacturing process that uses Polylactic Acid (PLA)—a renewable, biodegradable polymer—as its primary material. Unlike traditional subtractive manufacturing, it builds objects through layer-by-layer construction, making it ideal for complex designs. The most common technology for PLA printing is Fused Deposition Modeling (FDM), which melts PLA filament and extrudes it to form precise shapes. PLA’s plant-based origin (derived from corn starch or sugarcane) makes it a greener alternative to petroleum-based plastics, aligning with modern sustainability goals.

Our Capabilities: Delivering Customized Solutions

At Yigu Technology, we specialize in meeting diverse 3D printing needs with a range of core capabilities. Below is a breakdown of our key services, designed to support projects of all sizes and complexities:

| Capability | Key Features | Typical Use Cases | Turnaround Time |

| Custom 3D Printing | Tailored designs for unique requirements; flexible material and color options | Prototypes, personalized consumer products | 1–5 business days |

| High-Precision Printing | Dimensional accuracy down to ±0.1mm; tight tolerance ranges | Medical devices, automotive components | 2–7 business days |

| Large-Scale Production | Batch manufacturing for 100+ units; consistent quality control | Industrial parts, educational tools | 5–14 business days |

| Rapid Prototyping | Fast iteration cycles; quick design adjustments | Product development, concept testing | 24–48 hours |

| Multi-Material Printing | Combine PLA with other materials (e.g., PLA blends, flexible filaments) | Functional parts, textured surfaces | 3–7 business days |

The PLA 3D Printing Process

The PLA 3D printing workflow is straightforward but requires careful attention to detail to ensure quality. Here’s a step-by-step overview:

- Pre-Processing (Slicing): First, a 3D model (in STL format) is sliced into thin layers using software (e.g., Cura). This step defines layer thickness (typically 0.1–0.3mm) and print speed.

- Filament Extrusion: The 3D printer heats PLA filament to 190–220°C, melting it before extruding it through a nozzle onto the build plate.

- Layer-by-Layer Construction: The nozzle moves horizontally, depositing melted PLA to form each layer, which cools and adheres to the layer below.

- Post-Processing: After printing, the object is cooled, and any support structures are removed. Additional steps like sanding or painting may be added (see Section 5).

Quality Control: Each part is inspected for dimensional accuracy using tools like calipers, ensuring it meets precision levels and design specs.

Materials Used in PLA 3D Printing

PLA’s versatility is enhanced by various formulations, each suited to specific applications. Below are the most common materials we use:

| Material Type | Key Properties | Applications | Environmental Impact |

| PLA (Polylactic Acid) | Biodegradable, low warping, easy to print | Prototypes, consumer goods, educational tools | 100% compostable in industrial facilities |

| PLA Blends | Enhanced strength (e.g., PLA+wood, PLA+carbon) | Functional parts, decorative items | Still biodegradable (varies by blend) |

| Biodegradable Materials | Plant-based, zero petroleum content | Medical devices (e.g., dissolvable sutures) | Reduces plastic waste in landfills |

| Eco-Friendly Filaments | Recycled PLA, non-toxic additives | Sustainable packaging, toys | Low carbon footprint during production |

| Color Variants | Wide range of hues (matte, glossy, metallic) | Custom consumer products, branding items | No harmful dyes; color fades naturally in compost |

Surface Treatment for PLA 3D Prints

To improve the appearance and functionality of PLA parts, we offer several surface treatment options. These steps smooth rough layers and enhance durability:

- Sanding: Uses fine-grit sandpaper (400–2000 grit) to reduce layer lines. Ideal for parts needing a smooth finish (e.g., consumer products).

- Painting: Applies acrylic or spray paint to add color or protect the surface. Works well for decorative items or parts exposed to light wear.

- Coating: Uses clear coats (e.g., polyurethane) to increase water resistance and scratch protection. Suitable for outdoor or functional parts.

- Polishing: Uses compounds or heat (e.g., vapor polishing) to create a glossy finish. Common for high-end prototypes or display pieces.

Chemical Smoothing: Uses solvents (e.g., ethyl acetate) to melt the PLA surface slightly, eliminating layer lines. Effective for intricate designs but requires safety precautions.

Tolerances: Ensuring Precision in PLA 3D Printing

Tolerances are critical for PLA parts to fit and function as intended. Our printing processes adhere to strict standards, with key metrics outlined below:

| Tolerance Metric | Typical Range for PLA Prints | Measurement Techniques | Industry Benchmark Comparison |

| Dimensional Accuracy | ±0.1mm to ±0.3mm | Digital calipers, coordinate measuring machines (CMM) | Meets or exceeds FDM industry standards (±0.2mm average) |

| Layer Thickness | 0.1mm (fine) to 0.3mm (standard) | Printer software, optical microscopy | Finer than average FDM layer thickness (0.2–0.4mm) |

| Precision Levels | High (±0.1mm) for critical parts; Standard (±0.2mm) for general use | Quality control checklists, automated inspection tools | Suitable for medical (ISO 13485) and automotive (IATF 16949) requirements |

| Tolerance Ranges | Adjustable based on design needs; tighter tolerances available for a small fee | Design reviews with engineering team | Flexible to match project budgets and performance goals |

Advantages of PLA 3D Printing

PLA 3D printing offers numerous benefits over traditional manufacturing and other 3D printing materials:

- Cost-Effective: PLA filament is cheaper than materials like ABS or nylon, and FDM printers have lower upfront costs. This reduces project expenses, especially for small batches or prototypes.

- Environmentally Friendly: As a biodegradable polymer, PLA breaks down in compost facilities, reducing plastic pollution. It also uses less energy during production compared to petroleum-based plastics.

- Easy to Use: PLA has a low melting point (190–220°C) and minimal warping, making it ideal for beginners and high-volume printing. It requires no heated enclosure, simplifying printer setup.

- Wide Range of Applications: From consumer products to aerospace components, PLA’s versatility fits diverse industries. Its compatibility with multi-material printing expands design possibilities.

Customizability: PLA supports complex geometries (e.g., hollow structures, lattice designs) that are hard to achieve with traditional methods. Custom 3D printing lets you adjust sizes, colors, and features with ease.

PLA 3D Printing Applications by Industry

PLA 3D printing is transforming industries with its flexibility and sustainability. Below are key sectors we serve:

| Industry | Common Applications | Key Benefits for the Industry | Example Projects |

| Consumer Products | Custom phone cases, toys, home decor | Fast production, personalized designs | 3D-printed plant pots with custom logos |

| Medical Devices | Surgical guides, dissolvable sutures, prosthetic parts | Biocompatibility, precise sizing | PLA surgical splints for pediatric patients |

| Automotive Parts | Prototypes for dashboards, interior components | Lightweight, cost-effective testing | PLA prototypes for electric vehicle (EV) door handles |

| Aerospace Components | Non-critical parts (e.g., brackets, cable organizers) | Reduced weight, quick iteration | PLA brackets for satellite equipment testing |

| Educational Tools | Anatomical models, engineering kits | Safe (non-toxic), affordable for schools | 3D-printed DNA models for biology classrooms |

Manufacturing Techniques for PLA 3D Printing

While Fused Deposition Modeling (FDM) is the most common technique for PLA, other methods can be used for specific needs. Here’s a comparison:

| Technique | How It Works | Best for PLA Applications | Pros | Cons |

| Fused Deposition Modeling (FDM) | Melts and extrudes PLA filament layer by layer | Prototypes, functional parts, large-scale production | Low cost, easy to use, high speed | Visible layer lines (needs post-processing) |

| Stereolithography (SLA) | Uses UV light to cure PLA resin | High-detail parts (e.g., jewelry, dental models) | Ultra-smooth finish, high precision | Resin is more expensive; less eco-friendly |

| Selective Laser Sintering (SLS) | Uses a laser to sinter PLA powder | Strong, durable parts (e.g., industrial components) | No support structures needed | Higher cost; requires specialized equipment |

| Digital Light Processing (DLP) | Uses a digital projector to cure PLA resin | Fast printing of small, detailed parts | Faster than SLA for small batches | Limited build size |

| Binder Jetting | Deposits a binder onto PLA powder | Large, complex parts (e.g., architectural models) | Low cost for large parts | Lower strength compared to FDM |

PLA 3D Printing Case Studies: Our Success Stories

We’ve helped clients across industries achieve their goals with PLA 3D printing. Here are three notable examples:

Case Study 1: Medical Device Prototyping for a Healthcare Startup

- Challenge: A startup needed a fast, cost-effective way to test a new pediatric inhaler design.

- Solution: We used high-precision PLA 3D printing to create 10 prototypes in 48 hours. We applied chemical smoothing for a child-safe surface.

- Result: The client tested the prototypes, made design adjustments, and launched the final product 3 months faster than planned. The PLA’s biocompatibility ensured compliance with medical standards.

Case Study 2: Large-Scale Production for an Automotive Supplier

- Challenge: An auto supplier needed 500 PLA brackets for EV interior testing, with a 2-week deadline.

- Solution: We leveraged large-scale production capabilities, using FDM printers to batch-produce the brackets. We implemented strict quality control to ensure ±0.2mm dimensional accuracy.

- Result: All brackets were delivered on time, and the client saved 40% compared to traditional injection molding costs.

Case Study 3: Custom Educational Kits for a School District

- Challenge: A school district wanted affordable, eco-friendly science kits for 500 students.

- Solution: We created custom 3D printed PLA models (cells, gears) in bright color variants. The PLA’s non-toxic nature made it safe for classrooms.

Result: The kits were well-received, and the district reduced waste by 80% (compared to plastic kits) due to PLA’s biodegradability.

Why Choose Us for Your PLA 3D Printing Needs?

When you partner with Yigu Technology, you get more than just 3D printing—you get a team of experts dedicated to your success. Here’s why clients trust us:

- Expertise in PLA Printing: Our engineers have 5+ years of experience with PLA and FDM technology, ensuring optimal print settings for every project.

- High-Quality Results: We use premium PLA blends and strict quality control processes to deliver parts that meet or exceed your specs. Our tolerance ranges and precision levels are industry-leading.

- Customer Support: From design reviews to post-processing, our team is available 24/7 to answer questions and resolve issues. We work with you to refine your ideas and avoid costly mistakes.

- Fast Turnaround Times: Our rapid prototyping service delivers parts in 24–48 hours, and large-scale production is completed in 5–14 days—faster than most competitors.

Competitive Pricing: We offer transparent, affordable rates with no hidden fees. Our cost-effective solutions help you save money without compromising on quality.