Si alguna vez te has preguntado qué son los moldes de metal, como funcionan, o cual elegir para tu proyecto, estás en el lugar correcto. En pocas palabras, moldes de metal are specialized tools used to shape molten or solid metal into specific forms—think car parts, utensilios de cocina, o incluso joyas intrincadas. Son la columna vertebral de la fabricación., enabling mass production of consistent, high-quality metal products. Whether you’re a hobbyist making small metal crafts or a factory manager overseeing large-scale production, understanding metal molds is key to success. En esta guía, we’ll cover everything from the basics of how they function to advanced tips for maintenance, so you can make informed decisions and avoid common pitfalls.

What Are Metal Molds, and How Do They Work?

En su núcleo, metal molds are designed to give metal a precise shape. The process starts with preparing the mold, which is usually made from a durable material that can withstand high temperatures (since molten metal can reach thousands of degrees Fahrenheit). Once the mold is ready, molten metal—like aluminum, acero, or brass—is poured, injected, or pressed into the mold cavity. The metal then cools and hardens, taking on the exact shape of the cavity. Después de enfriar, se abre el molde, and the finished part is removed.

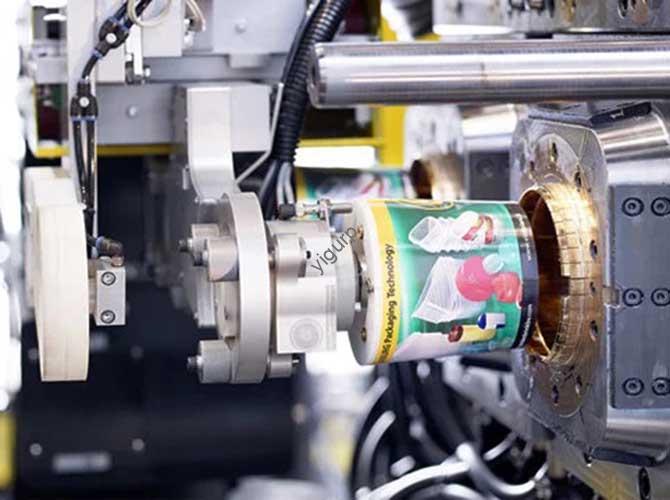

Let’s take a real-world example: a small automotive parts manufacturer. They use moldes de fundición a presión (a type of metal mold) to make aluminum engine brackets. The mold is made of two steel halves, each with a cavity shaped like the bracket. Molten aluminum is injected into the cavity under high pressure (generalmente 1,000 a 5,000 psi). Within minutes, the aluminum cools and hardens. The mold halves separate, and the bracket is taken out—ready for further processing like trimming or painting. This process allows the manufacturer to make hundreds of identical brackets every hour, which is why die casting is so popular in automotive manufacturing.

It’s important to note that not all metal molds work the same way. Some use gravity to fill the cavity (gravity casting molds), while others use pressure (die casting or compression molding). The method depends on the type of metal, the complexity of the part, y el volumen de producción. We’ll dive deeper into these types next.

Common Types of Metal Molds: Usos, Ventajas, and Cons

Choosing the right type of metal mold is critical—pick the wrong one, and you could end up with low-quality parts, tiempo perdido, or high costs. Below is a breakdown of the most common types, along with their best uses, ventajas, and disadvantages.

| Type of Metal Mold | Mejor para | Ventajas | Contras |

| Moldes de fundición a presión | Mass production of small to medium parts (p.ej., carcasas de teléfonos inteligentes, piezas de juguete) | Producción rápida (arriba a 1,000 partes/hora), alta precisión, low labor costs | High initial mold cost (can be \(10,000–)100,000+), limited to non-ferrous metals (aluminio, zinc, magnesio) |

| Sand Casting Molds | Grande, piezas simples (p.ej., tapas de alcantarilla, bloques de motor) | Low initial cost, can handle large parts (arriba a 100+ montones), works with ferrous metals (acero, iron) | Producción lenta (1–10 parts/hour), lower precision (acabado superficial rugoso), mold is single-use |

| Investment Casting Molds (Lost-Wax Casting) | Intricate parts (p.ej., joyas, palas de turbina) | Exceptional precision (fine details), smooth surface finish, works with most metals | Producción lenta (1–5 parts/hour), high material costs (cera, cerámico), not ideal for large parts |

| Compression Molding Molds | Solid metal parts (p.ej., engranajes, pernos) | Good for high-strength parts, works with both ferrous and non-ferrous metals | Limited to simple shapes, requires high pressure (arriba a 10,000 psi), slower than die casting |

Let’s look at another example to illustrate the difference. A jewelry maker creating delicate silver necklaces would use investment casting molds. Here’s why: investment casting can capture tiny details like engravings or filigree, which sand casting or die casting can’t. The process involves making a wax model of the necklace, covering it in ceramic (the mold), melting the wax out (hence “lost-wax”), and pouring molten silver into the ceramic cavity. The result is a necklace with a smooth, detailed finish that needs little to no extra polishing. Por otro lado, a construction company making manhole covers would choose sand casting molds—they’re cheap, can handle the large size of manhole covers, and don’t require the same precision as jewelry.

Key Factors to Consider When Choosing Metal Molds

Now that you know the main types of metal molds, how do you pick the right one for your project? Here are the most important factors to weigh, based on industry experience and best practices.

1. Material of the Mold

The mold material itself matters a lot—it affects durability, resistencia al calor, y costo. The most common mold materials are:

- Acero: Ideal for die casting and compression molding. It’s strong, a prueba de calor (can handle up to 2,800°F), and lasts for thousands of uses. Sin embargo, steel molds are expensive to make.

- Hierro fundido: Used in sand casting and some die casting applications. It’s cheaper than steel but less durable—good for low to medium production volumes.

- Cerámico: Used in investment casting. It’s great for capturing fine details but is brittle and single-use.

- Sand: Used in sand casting. It’s the cheapest option but is only good for one use and has low precision.

Un estudio de caso: A furniture manufacturer making metal chair legs. They initially used a cast iron die casting mold, but after 5,000 regiones, the mold started to wear down, leading to uneven leg shapes. They switched to a steel mold, which lasted for 50,000 parts—saving them money in the long run, even though the steel mold cost 3x more upfront.

2. Type of Metal Being Shaped

Not all molds work with all metals. Por ejemplo:

- Metales no ferrosos (aluminio, zinc, magnesio): Best for die casting, as they have lower melting points (aluminum melts at 1,220°F, zinc at 787°F).

- Ferrous metals (acero, iron): Require molds that can handle higher temperatures (steel melts at 2,500°F). Sand casting or investment casting are better options here.

- metales preciosos (oro, plata): Investment casting is preferred for its precision and ability to handle small, partes intrincadas.

3. Volumen de producción

How many parts do you need to make? This is a make-or-break factor:

- Alto volumen (10,000+ regiones): Die casting molds are the way to go. The high initial cost is offset by fast production times and low per-part costs.

- Medium volume (1,000–10.000 piezas): Compression molding or reusable sand casting molds (called “permanent mold casting”) work well.

- Low volume (1–1.000 piezas): Sand casting (single-use) or investment casting are more cost-effective, as you don’t need to invest in an expensive, durable mold.

4. Part Complexity and Precision

If your part has fine details (like a gear with small teeth) or tight tolerances (p.ej., a part that needs to fit with another part within 0.001 pulgadas), investment casting or die casting are better. Sand casting is good for simple shapes but can’t match the precision of these methods.

Por ejemplo, a medical device manufacturer making stainless steel surgical tools needs extremely high precision. They use investment casting because it can produce tools with tolerances as tight as ±0.002 inches—critical for tools that need to work safely and effectively in surgeries.

How to Maintain Metal Molds for Longevity

A well-maintained metal mold can last for years (or even decades), saving you money on replacements. Here’s a step-by-step guide to keeping your molds in top shape, based on industry standards.

Paso 1: Clean the Mold After Each Use

Molten metal can leave residue (like oxide layers or metal shavings) in the mold cavity. If left uncleaned, this residue can:

- Ruin the shape of future parts (causing blemishes or uneven surfaces).

- Damage the mold (residue can scratch or corrode the cavity).

How to clean: Use a soft-bristle brush or compressed air to remove loose residue. For tough residue, use a mild solvent (like mineral spirits) that’s safe for the mold material (avoid harsh chemicals that can etch steel or iron). For investment casting molds (cerámico), discard them after use—they’re single-use.

Paso 2: Inspect for Wear and Tear Regularly

Even with cleaning, molds can wear down over time. Check for these issues every 100–500 uses (more often for high-volume production):

- Cracks or chips in the cavity: These can cause parts to have missing pieces or rough edges.

- Warping: High temperatures can cause the mold to bend, leading to misshapen parts.

- Rust or corrosion: Especially common with steel or iron molds if they’re exposed to moisture.

What to do if you find issues: Small cracks can be repaired with welding (for steel molds), but large cracks mean the mold needs to be replaced. Rust can be removed with a wire brush and rust inhibitor, but if the rust has eaten into the cavity, replacement is better.

Paso 3: Lubricate Moving Parts

If your mold has moving parts (like the halves of a die casting mold that open and close), lubricate them every 50–100 uses. Use a high-temperature lubricant (rated for at least 500°F) to prevent friction from wearing down the parts. Avoid using too much lubricant—excess can get into the mold cavity and ruin parts.

Paso 4: Store Molds Properly

When not in use, store molds in a dry, cool place (between 60–80°F, with humidity below 50%). For steel or iron molds, coat them in a rust-preventive oil to keep moisture out. Avoid stacking heavy objects on top of molds, as this can cause warping.

Un ejemplo del mundo real: A tool and die shop that specializes in die casting molds. They follow a strict maintenance schedule: cleaning each mold after use, inspecting for wear weekly, lubricating moving parts every 75 usos, and storing molds in a climate-controlled room. Como resultado, their molds last an average of 100,000 uses—twice as long as the industry average of 50,000 usos.

Latest Trends in Metal Mold Technology (2025)

The metal mold industry is always evolving, with new technologies making molds more efficient, preciso, and eco-friendly. Here are the top trends to watch this year, based on data from industry reports (like the American Foundry Society’s 2025 Manufacturing Trends Report).

1. 3D-Printed Metal Molds

3impresión D (fabricación aditiva) is changing how molds are made. Instead of machining a mold from a solid block of steel (which can take weeks), 3D printers build molds layer by layer from metal powder (like stainless steel or titanium). This has several benefits:

- Producción más rápida: A 3D-printed die casting mold can be made in 1–3 days, compared to 2–4 weeks for a machined mold.

- Diseños complejos: 3D printing can create mold cavities with intricate shapes (like internal channels for cooling) that are impossible to machine.

- Residuos reducidos: Machining removes up to 70% of the metal block as waste, while 3D printing uses only the powder needed for the mold.

According to the American Foundry Society, 3D-printed metal molds are expected to make up 15% of all die casting molds by 2027—up from just 3% en 2023. A good example is a aerospace parts manufacturer that uses 3D-printed molds to make titanium turbine blades. The 3D-printed mold has internal cooling channels that speed up the cooling time of the molten titanium, reducing production time by 40%.

2. Eco-Friendly Mold Materials

As sustainability becomes a bigger focus, manufacturers are switching to eco-friendly mold materials. Por ejemplo:

- Recycled steel: Molds made from recycled steel have the same durability as new steel but use 74% less energy to produce (per the World Steel Association).

- Biodegradable sand binders: In sand casting, sand is held together with binders. Traditional binders are made from chemicals that are harmful to the environment, but new biodegradable binders (made from corn starch or soy) break down naturally, reducing pollution.

A construction equipment manufacturer in Europe has switched to using recycled steel for their sand casting molds. They’ve reduced their carbon footprint by 30% y salvado 15% on material costs—proving that sustainability can be cost-effective.

3. Smart Molds with Sensors

Smart molds have sensors embedded in the cavity that monitor temperature, presión, and part quality in real time. These sensors send data to a computer, which alerts operators to issues (like too much pressure or uneven cooling) before they ruin a batch of parts. Benefits include:

- Menos defectos: Smart molds reduce defect rates by up to 50% (per a study by the Society of Manufacturing Engineers).

- Menos desperdicio: By catching issues early, you don’t have to throw away entire batches of bad parts.

- Predictive maintenance: Sensors can track mold wear and tell you when a mold needs to be cleaned or repaired—before it breaks down.

A consumer electronics company that makes zinc smartphone casings uses smart die casting molds. The sensors monitor the temperature of the molten zinc and adjust the cooling time automatically. This has reduced their defect rate from 8% a 2%, saving them $200,000 a year in wasted materials.

Yigu Technology’s View on Metal Molds

En Yigu Tecnología, we believe metal molds are the foundation of modern manufacturing—they bridge the gap between design and real-world products. From our experience working with clients in automotive, aeroespacial, y bienes de consumo, the biggest challenge many face is balancing cost, precisión, y velocidad de producción. That’s why we recommend a “future-proof” approach: investing in durable, adaptable molds (like 3D-printed or smart molds) that can handle changing production needs. We also see sustainability as non-negotiable—using recycled materials and eco-friendly processes isn’t just good for the planet; it’s good for long-term profitability. Whether you’re a small business or a large manufacturer, the key is to choose a mold that fits your current project while leaving room to grow. With the right mold and maintenance plan, you can produce high-quality parts efficiently, reducir el desperdicio, and stay ahead in a competitive market.

FAQ About Metal Molds

1. How much does a metal mold cost?

Costs vary widely based on type, tamaño, y material. A simple sand casting mold can cost as little as \(50–)200, while a high-precision 3D-printed die casting mold for automotive parts can cost \(50,000–)200,000+. For most small to medium projects, expect to pay \(1,000–)10,000.

2. Can metal molds be reused?

It depends on the type. Die casting, compression, and permanent mold casting molds are reusable (steel or iron molds can last 10,000–100,000+ uses). Sand casting and investment casting molds are usually single-use—sand molds break when removing the part, and ceramic investment molds are destroyed to get the part out.

3. What’s the difference between die casting and sand casting?

Die casting uses high pressure to inject molten metal into a steel mold (rápido, preciso, good for high volume). Sand casting uses gravity to pour molten metal into a sand mold (lento, menos preciso, good for large, piezas de bajo volumen). Die casting is better for small, partes detalladas (p.ej., phone casings), while sand casting is better for large parts (p.ej., bloques de motor).

4. How long does it take to make a metal mold?

Again, it depends on the type. A sand casting mold can be made in a few hours. A machined die casting mold takes 2–4 weeks. A 3D-printed metal mold is faster—1–3 days. The complexity of the part also plays a role: a simple mold (p.ej., a square block) is faster to make than a complex mold (p.ej., a gear with 50 teeth).

5. What’s the most durable type of metal mold?

Steel molds are the most durable. They can withstand high temperatures, presión alta, and repeated use—some steel die casting molds last for 100,000+ regiones. Cast iron molds are also durable but not as long-lasting as steel (usually 10,000–50,000 parts).