¿Alguna vez ha tenido dificultades para encontrar un método de mecanizado que equilibre la alta precisión?, producción rápida, y diseño de piezas complejas para componentes metálicos? CNC machining hardware—the computer-controlled process for metal parts manufacturing—solves these pain points for industries from aerospace to electronics. Esta guía desglosa sus principales beneficios., flujo de trabajo paso a paso, desafíos comunes, and how to choose the right solution, helping you achieve reliable, high-quality hardware parts every time.

1. What Makes CNC Machining Hardware Stand Out? Ventajas clave

Compared to traditional manual machining (p.ej., using lathes or milling machines operated by hand), CNC machining hardware offers four game-changing benefits. The table below clearly contrasts its performance with traditional methods:

| Ventaja | Hardware de mecanizado CNC | Traditional Manual Machining |

| Precisión | Computer-controlled tool paths; dimensional error as low as ±0.005mm; consistent surface quality (Real academia de bellas artes < 1.6µm) | Relies on operator skill; error often ≥0.1mm; uneven surface finish |

| Eficiencia | 24/7 continuous operation; automated tool changes cut production time by 40-60%; handles high-volume orders (1000+ partes/día) | Limited by operator fatigue; manual tool changes add 2-3x more time; suited for small batches (≤50 parts/day) |

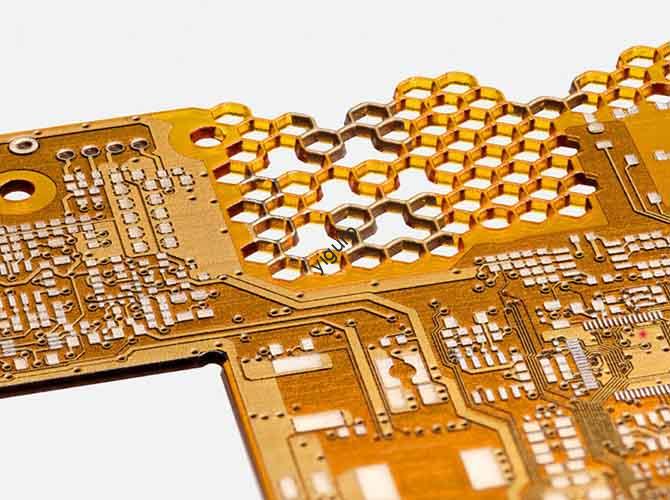

| Complexity Capability | Programs handle curved surfaces, porous structures, and custom shapes (p.ej., 3D-formed brackets); no manual adjustment needed | Struggles with non-linear designs; requires frequent operator tweaks for complex parts |

| Consistencia | 99.5%+ defect-free rate for mass production; every part matches the digital model exactly | Defect rate often ≥5%; part-to-part variation is common |

Por ejemplo, en la industria automotriz, CNC machining hardware produces engine cylinder heads with 12+ precision holes—each aligned within 0.01mm of the design. Traditional machining would take 3x longer and risk misalignment, leading to engine leaks.

2. Step-by-Step Workflow for CNC Machining Hardware

Achieving perfect hardware parts requires a linear, 3-stage process—each step builds on the previous one to avoid errors. Skipping any step can lead to wasted materials or faulty parts:

2.1 Pre-Machining: Modelado, Programación, and Setup

This stage lays the foundation for success. Follow these key actions:

- 3Modelado D: Create a digital model of the hardware part using CAD software (p.ej., SolidWorks, autocad). The model must include exact dimensions, material specs (p.ej., aluminio 6061, acero inoxidable 304), y requisitos de tratamiento de superficies (p.ej., galvanoplastia, oxidación).

- Programación CNC: Convert the CAD model to a G-code program (El lenguaje que entienden las máquinas CNC.). The program defines:

- Tool selection (p.ej., end mill for milling, drill bit for holes)

- Cutting speed (100-300m/min for steel, 300-500m/min for aluminum)

- Tasa de alimentación (50-200mm/min, depending on material hardness)

- Diseño de accesorios & Clamping: Choose or build a fixture to hold the raw material (p.ej., metal block) securely. Para piezas complejas (p.ej., componentes de dispositivos médicos), custom fixtures prevent movement during machining—even a 0.05mm shift ruins precision.

- Critical Note: Providing inaccurate CAD drawings is the #1 cause of pre-machining delays. Double-check dimensions (p.ej., hole depth, edge angles) before sending files to the manufacturer.

2.2 In-Machining: Automated Cutting

Once setup is complete, the CNC machine takes over. The process typically includes three sequential steps (递进式 layer-by-layer refinement):

- Roughing: Removes most of the excess material quickly (p.ej., shaping a 100mm metal block into a 50mm prototype). This step prioritizes speed but leaves a rough surface.

- Semi-Finishing: Trims the part closer to the final shape (p.ej., reducing surface roughness from Ra 6.3μm to Ra 3.2μm). It prepares the part for the final step.

- Refinamiento: Achieves the exact dimensions and surface quality (p.ej., Ra 1.6μm for visible parts). This step uses slower cutting speeds to avoid tool marks.

- Ejemplo: For a smartphone aluminum shell, finishing ensures the edges are smooth to the touch—no burrs or scratches that could harm users.

2.3 Post-mecanizado: Refinement & Control de calidad

Después de cortar, the part needs final touches to meet design standards:

- Desbarbado: Removes sharp edges or leftover material (p.ej., using a wire brush or ultrasonic cleaner).

- Tratamiento superficial: Applies coatings to improve durability or appearance (p.ej., painting for corrosion resistance, anodizing for a matte finish).

- Inspección de calidad: Use tools like calipers, micrómetros, or 3D scanners to verify dimensions. If a part is out of tolerance (p.ej., a hole that’s 0.02mm too small), it’s either reworked or discarded.

3. Arriba 4 Applications of CNC Machining Hardware

CNC machining hardware is essential across industries that demand precision and reliability. The table below highlights key use cases and why CNC is the best choice:

| Industria | Hardware Part Example | Key Requirement Addressed by CNC Machining |

| Aeroespacial | Aircraft engine turbine blades, fuselage brackets | Alta resistencia (handles 1000+°C temperatures); alineación de precisión (avoids engine failure) |

| Dispositivos médicos | Surgical scalpel handles, componentes del implante (p.ej., reemplazos de cadera) | Biocompatibilidad (uses medical-grade stainless steel); ultra-low defect rate (99.9%+ seguridad) |

| Electrónica | Smartphone metal frames, pines del conector | Miniaturización (machines parts as small as 0.5mm); high consistency (10,000+ identical pins/day) |

| Automotor | Engranajes de transmisión, pinzas de freno | Resistencia al desgaste (manijas 100,000+ km of use); mass production efficiency (500+ gears/hour) |

- Estudio de caso: A medical device manufacturer used CNC machining hardware producir 500 hip implant stems. Each stem had a 0.01mm tolerance for the connection to the hip socket—CNC ensured 100% of parts met this standard, avoiding patient complications.

4. Yigu Technology’s Perspective on CNC Machining Hardware

En Yigu Tecnología, we believe CNC machining hardware is the backbone of modern manufacturing—especially for industries where precision can’t be compromised. Our clients (from auto parts makers to medical device firms) often see a 35% boost in production efficiency after switching to our CNC solutions, thanks to our high-speed machines (equipped with Fanuc 0i-MF systems) and custom fixture design. We prioritize cost control too: by optimizing tool paths and using durable materials, we help small-to-medium businesses reduce machining costs by 20-25%. For ultra-precise parts (p.ej., componentes aeroespaciales), our 5-axis CNC machines deliver ±0.003mm accuracy—setting a new standard for reliability.

FAQ About CNC Machining Hardware

- q: How long does a typical CNC machining hardware project take?

A: It depends on complexity: piezas simples (p.ej., a basic bracket) llevar 1-3 días (including setup and machining); partes complejas (p.ej., implantes medicos) llevar 5-10 días (due to custom fixtures and strict quality checks). Always ask the manufacturer for a detailed timeline.

- q: Is CNC machining hardware more expensive than 3D printing for metal parts?

A: Para lotes pequeños (≤10 parts), 3D printing may be cheaper. But for large batches (≥100 parts), CNC machining hardware es 20-30% cheaper—its faster speed and lower material waste offset initial setup costs.

- q: What should I look for when choosing a CNC machining hardware manufacturer?

A: Prioritize three things: 1) Equipo (p.ej., 5-axis machines for complex parts); 2) Experiencia (ask for case studies in your industry, like aerospace or medical); 3) Quality control processes (p.ej., 100% inspection vs. random sampling). Good after-sales service (p.ej., reworking defective parts) is also key.