3Modelo Gundam de impresión D: Una guía completa para entusiastas de la creación de obras maestras personalizadas

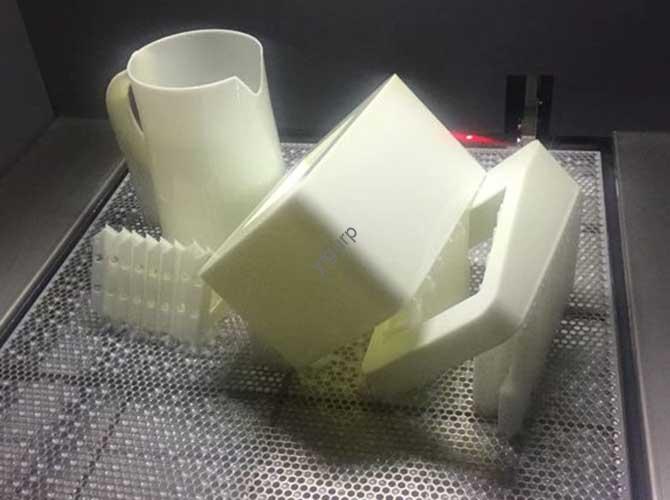

Para los entusiastas de Gundam, Construir y personalizar modelos es más que un pasatiempo: es una forma de expresar creatividad y amor por la icónica franquicia.. Pero los kits tradicionales de Gundam (llamado gunpla) a menudo limitan la personalización: estás atrapado con piezas prefabricadas, colores fijos, y diseños estándar. Ahí es donde entra en juego la tecnología de impresión 3D de modelos Gundam. Te permite crear […]