Lo que necesita saber sobre las piezas de moldeo de plástico compuesto de silicona?

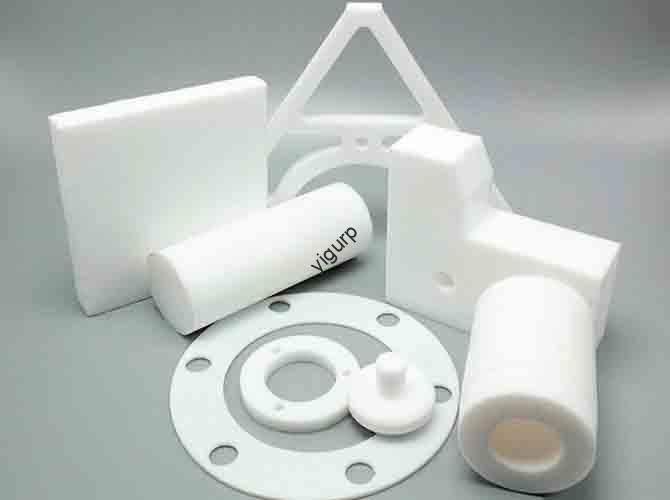

Silicone composite plastic molding parts are specialized components produced by copying plastic parts using silicone molds—a process that balances precision, rentabilidad, y flexibilidad. Unlike traditional metal mold manufacturing, this method leverages silicone’s elasticity to replicate intricate details while keeping small-batch production costs low. This article breaks down the core principles, proceso paso a paso, ventajas, limitaciones, y […]