Nuestros servicios de impresión 3D de aluminio

Libera el poder del peso ligero, piezas de alto rendimiento con Impresión 3D de aluminio—la fusión de tecnologías avanzadas fabricación aditiva y materiales de aluminio versátiles. Desde componentes aeroespaciales hasta piezas de automoción, nuestras soluciones ofrecen inigualable libertad de diseño, arriba a 50% reducción de peso, y tiempos de respuesta más rápidos. Ya sea que necesite prototipos rápidos o producción en gran volumen, Convertimos tus diseños digitales en duraderos., Piezas de aluminio de precisión que elevan el rendimiento y reducen los costos.

¿Qué es la impresión 3D de aluminio??

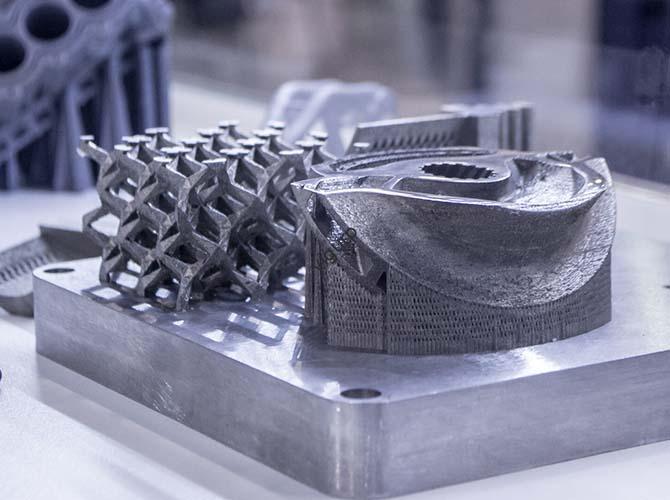

Impresión 3D de aluminio es un innovador fabricación aditiva proceso que transforma polvo de aluminio en partes funcionales mediante fabricación capa por capa. A diferencia de los métodos tradicionales (p.ej., fundición, mecanizado), construye piezas directamente a partir de diseños digitales, convirtiendo un Diseño digital a objeto físico. sin necesidad de costosos moldes o herramientas.

En su núcleo, Esta tecnología aprovecha las ventajas naturales del aluminio.: bajo peso (densidad: 2.7 gramos/cm³), alta relación resistencia-peso, y excelente resistencia a la corrosión. Combinando estas propiedades con la flexibilidad de la impresión 3D, Permite geometrías complejas. (p.ej., celosías internas, estructuras huecas) que alguna vez fueron imposibles de producir con la fabricación tradicional de aluminio.

Conceptos básicos clave de la impresión 3D de aluminio:

| Término | Descripción | Papel en el proceso |

| Polvo de aluminio | Bien, partículas esféricas (15-45μm) utilizado como materia prima | La materia prima se funde o sinteriza para formar capas. |

| Fabricación capa por capa | Piezas de construcción una capa delgada. (0.02–0,1 mm) a la vez | Garantiza que los diseños complejos se produzcan con precisión y sin defectos estructurales. |

| Fabricación Aditiva | Agregar material solo donde sea necesario (vs. eliminación de material en el mecanizado) | Reduce el desperdicio (de 70% en mecanizado para <10% en impresión 3D) |

Nuestras capacidades: Ofreciendo excelencia en impresión 3D de aluminio

En Yigu Tecnología, nuestro Capacidades de impresión 3D de aluminio están diseñados para satisfacer las diversas necesidades de las industrias, desde la aeroespacial hasta la de bienes de consumo. Combinamos herramientas de vanguardia con experiencia técnica para ofrecer resultados consistentes., resultados de alta calidad:

- Equipos de última generación: Utilizamos máquinas de grado industrial. (p.ej., EOS M 290, Soluciones SLM 280) optimizado para aluminio, capaz de imprimir piezas con densidades de hasta 99.8% y impresión de alta precisión (Tolerancias tan ajustadas como ±0,05 mm.).

- Soluciones personalizadas: Ya sea que necesite un soporte aeroespacial liviano o un componente de bienes de consumo personalizado, adaptamos cada paso (desde la selección de materiales hasta el posprocesamiento) a sus requisitos únicos.

- Creación rápida de prototipos: Convierta su diseño digital en un prototipo físico de aluminio en solo 3 a 5 días, acelerando el ciclo de desarrollo de su producto al 50% vs. métodos tradicionales.

- Producción en volumen: Ampliar hasta 10,000+ piezas mensualmente con calidad constante: nuestro flujo de trabajo automatizado garantiza que cada pieza cumpla con sus especificaciones, incluso a grandes volúmenes.

- Soporte de extremo a extremo: De la optimización del diseño al posprocesamiento, Nuestro equipo lo guía en cada etapa, garantizando que su proyecto se mantenga a tiempo y dentro del presupuesto.

Mesa: Nuestras capacidades de impresión 3D de aluminio frente a. Promedios de la industria

| Capacidad | Rendimiento de la tecnología Yigu | Promedio de la industria |

| Tamaño máximo de impresión | 300mm × 300 mm × 400 mm | 250mm × 250 mm × 300 mm |

| Plazo de entrega de prototipos | 3–5 días | 7–10 días |

| Capacidad de producción | Arriba a 8,000 partes/semana | Arriba a 3,000 partes/semana |

| Densidad de piezas | 99.5–99,8% | 95–98% |

| Desperdicio de materiales | <8% | 15–20% |

Proceso: El flujo de trabajo paso a paso para la impresión 3D de aluminio

Nuestro Proceso de impresión 3D de aluminio es una estructura, Flujo de trabajo optimizado que tiene en cuenta las propiedades únicas del aluminio. (p.ej., alta conductividad térmica) para garantizar la confiabilidad:

- Preprocesamiento:

- Optimización del diseño digital: Nuestro equipo revisa su modelo CAD para optimizarlo para aluminio, p., agregando soportes mínimos (para reducir el posprocesamiento) y garantizar que el espesor de la pared sea ≥0,3 mm (para evitar fallos de impresión).

- Conversión de archivos & rebanar: Convertimos el modelo CAD a un archivo STL y utilizamos software de corte avanzado (p.ej., Magias) dividirlo en capas (0.02–0,1 mm de espesor) y configurar los parámetros de impresión (p.ej., potencia del láser: 300–400W para aleaciones de aluminio).

- Ejecución de impresión:

- Las técnicas más comunes para el aluminio son Fusión selectiva por láser (SLM) y Sinterización directa por láser de metales (DMLS). Un láser de alta potencia se funde polvo de aluminio capa por capa, fusionándolo en una parte densa. Para piezas más grandes, podemos usar Fusión por haz de electrones (MBE)—Más rápido que SLM e ideal para aleaciones de aluminio de alta temperatura.

- Postprocesamiento:

- Eliminación de soporte: Retiramos con cuidado los soportes metálicos. (mediante mecanizado o electroerosión por hilo) para evitar dañar la pieza de aluminio.

- Tratamiento térmico: Las piezas se someten a un tratamiento térmico T6. (recocido en solución + envejecimiento) para aumentar la resistencia: aluminio 6061, Por ejemplo, alcanza una resistencia a la tracción de 310 MPa después del tratamiento térmico.

- Acabado de superficies: realizamos chorro de arena, pulido, o anodizado para mejorar la estética y la resistencia a la corrosión (p.ej., El anodizado añade una capa protectora de óxido a las piezas de aluminio.).

- Control de calidad:

Cada pieza es inspeccionada con:

- Exploraciones por tomografía computarizada con rayos X para verificar la porosidad interna.

- Máquinas de medición de coordenadas (CMM) verificar precisión dimensional.

Pruebas de tracción para garantizar que cumple con los estándares de resistencia. (p.ej., aluminio 7075: mínimo 570 Resistencia a la tracción MPa).

Materiales: Elegir el aluminio adecuado para su proyecto

No todos los materiales de aluminio son iguales: ofrecemos una gama de aleaciones de aluminio y compuestos para satisfacer las demandas de su aplicación. Así es como se comparan nuestros materiales:

| Tipo de material | Propiedades clave | Aplicaciones ideales |

| Aluminio 6061 | buena fuerza (310 MPa después del tratamiento térmico), excelente resistencia a la corrosión | Piezas automotrices (p.ej., Soportes de batería para vehículos eléctricos), bienes de consumo |

| Aluminio 7075 | Alta resistencia (570 MPa después del tratamiento térmico), bajo peso | Componentes aeroespaciales (p.ej., soportes de ala), piezas industriales de alto estrés |

| Aluminio 1050 (Aluminio puro) | Alta ductilidad, excelente conductividad térmica | Electrónica (p.ej., disipadores de calor), piezas decorativas |

| Aluminio reforzado con fibra de carbono | 40% mayor resistencia que el aluminio estándar, ultraligero | Piezas aeroespaciales de alto rendimiento, componentes de automoción de carreras |

| Aluminio aleado con silicio (AlSi10Mg) | Buena imprimibilidad, alta resistencia a la fatiga | Prototipos, piezas industriales de baja tensión |

Nosotros obtenemos polvos metálicos de proveedores confiables: se prueba la pureza de cada lote (mínimo 99.9% contenido de aluminio) y fluidez para garantizar una calidad de impresión constante.

Tratamiento superficial: Mejora del rendimiento y la estética de las piezas de aluminio

La superficie natural del aluminio se puede mejorar con tratamiento superficial para aumentar la durabilidad, resistencia a la corrosión, y atractivo visual. Nuestros servicios se adaptan a las propiedades del aluminio.:

- Arenado: Crea un acabado mate uniforme (rugosidad superficial Ra: 1–3 μm) que oculta líneas de capas menores, ideal para piezas industriales (p.ej., paréntesis, carcasas).

- Pulido: Logra una suave, acabado reflectante (Real academia de bellas artes <0.2µm) para piezas orientadas al consumidor (p.ej., bienes de lujo, adornos automotrices).

- Anodizado: Forma una capa protectora de óxido. (5–25μm de espesor) que aumenta la resistencia a la corrosión al 300% y permite la personalización del color (p.ej., negro, plata, oro).

- Revestimiento: Aplica capas finas como cerámica. (para mayor resistencia al calor) o recubrimiento en polvo (para resistencia al rayado) para extender la vida útil de las piezas, perfecto para piezas de alto desgaste (p.ej., herramientas, componentes automotrices).

- Acabado de superficies: Incluye desbarbado (eliminar bordes afilados) y limpieza química para garantizar que las piezas estén listas para su uso o montaje.

Mesa: Impacto del tratamiento superficial en el rendimiento de las piezas de aluminio

| Tratamiento | Rugosidad de la superficie (Real academia de bellas artes) | Resistencia a la corrosión (Prueba de niebla salina) | Resistencia al desgaste |

| Tal como está impreso | 5-10 μm | 48 horas (sin óxido) | Bajo (propenso a rayarse) |

| Arenado | 1–3μm | 96 horas (sin óxido) | Medio |

| Anodizado | 0.5–2μm | 500+ horas (sin óxido) | Alto |

| Pulido + Recubierto | <0.2µm | 600+ horas (sin óxido) | Muy alto |

Tolerancias: Precisión en la que puede confiar

Para piezas de aluminio utilizadas en aplicaciones críticas (p.ej., aeroespacial, dispositivos médicos), tolerancias y precisión dimensional no son negociables. Nuestro proceso garantiza una consistencia, tolerancias estrictas:

- Límites de tolerancia:

- Para piezas de aluminio impresas con SLM/DMLS: ±0,05 mm para piezas de hasta 50 mm, ±0,1 mm para piezas de hasta 200 mm, y ±0,2 mm para piezas de hasta 300 mm.

- Para piezas impresas con EBM: Tolerancias ligeramente más amplias (±0,1–0,3 mm) pero velocidades de producción más rápidas.

- Técnicas de medición: Utilizamos herramientas calibradas como escáneres láser. (exactitud: ±0,001 mm) y CMM para verificar cada dimensión, garantizando el cumplimiento de seguro de calidad estándares (p.ej., ISO 8062 para piezas metálicas).

- Control de precisión: Nuestras impresoras se calibran semanalmente para el enfoque del láser y el nivel de la cama., y utilizamos sistemas de retroalimentación de circuito cerrado para ajustar los parámetros (p.ej., velocidad del láser, temperatura del lecho de polvo) en tiempo real para evitar desviaciones.

Por ejemplo, Nuestros componentes aeroespaciales de aluminio tienen una tolerancia de ±0,08 mm, lo que cumple con los estrictos requisitos de AS9100. (gestión de calidad aeroespacial).

Ventajas: Por qué la impresión 3D de aluminio supera a los métodos tradicionales

Impresión 3D de aluminio Ofrece una variedad de beneficios que lo convierten en una opción superior para la fabricación moderna.:

- Libertad de diseño: Crea geometrías complejas (p.ej., canales internos, estructuras reticulares) que son imposibles con fundición o mecanizado, ahorrando peso (arriba a 50%) y mejorar el rendimiento (p.ej., mejor disipación de calor en electrónica).

- Reducción de peso: El aluminio es 3 veces más liviano que el acero y 1,5 veces más liviano que el titanio, ideal para industrias como la aeroespacial y la automotriz., donde el peso impacta directamente la eficiencia del combustible (a 10% La reducción de peso en un automóvil mejora la economía de combustible en aproximadamente un 6%.).

- Rentabilidad: Para lotes pequeños y medianos (10–1.000 piezas), 3La impresión D elimina herramientas costosas (ahorrando entre un 40% y un 60% frente a. fundición) y reduce el desperdicio de material (de 70% en mecanizado para <8% en impresión 3D).

- Plazo de entrega reducido: Los prototipos están listos en 3 a 5 días. (vs. 2–4 semanas para el casting) y los plazos de producción se reducen en un 50%, lo que permite que su producto llegue al mercado más rápido.

Rendimiento mejorado: 3Las piezas de aluminio impresas en D tienen mejor resistencia a la fatiga que las piezas fundidas (debido a la estructura uniforme del grano) y se puede optimizar para cargas específicas (p.ej., estructuras reticulares que absorben el impacto).

Aplicaciones Industria: Donde brilla la impresión 3D de aluminio

El peso ligero del aluminio, fuerte, y sus propiedades resistentes a la corrosión lo convierten en un material versátil en todas las industrias.. Así es como estamos usando Impresión 3D de aluminio para resolver desafíos del mundo real:

| Industria | Aplicaciones clave | Por qué aluminio? |

| Aeroespacial | Soportes de ala, componentes del motor, partes de satelite | Alta relación resistencia-peso, resistencia al calor (hasta 200°C para 7075 aleación) |

| Automotor | Carcasas para baterías de vehículos eléctricos, piezas de suspensión, adornos personalizados | Reducción de peso (mejora el alcance), resistencia a la corrosión (sin óxido) |

| Dispositivos médicos | Instrumentos quirúrgicos, implantes ortopédicos (p.ej., placas óseas) | Biocompatibilidad (aluminio de grado médico), ligero (reduce la incomodidad del paciente) |

| Electrónica | Disipadores de calor, carcasas de conectores, componentes de la antena | Excelente conductividad térmica, blindaje electromagnético |

| Bienes de consumo | Cajas de relojes de lujo, equipo deportivo (p.ej., cuadros de bicicleta), soportes para portátiles | Estética, ligero, durabilidad |

Técnicas de fabricación: Combinando el método correcto con su proyecto de aluminio

Utilizamos una gama de Técnicas de fabricación de Impresión 3D de Aluminio para optimizar la calidad de la pieza, costo, y velocidad:

| Técnica | Cómo funciona | Mejor para | Rango de volumen | Costo por pieza (100 unidades) |

| Fusión selectiva por láser (SLM) | El láser funde polvo de aluminio en partes densas (99.5–99,8% de densidad) | Piezas de uso final de alta precisión (p.ej., componentes aeroespaciales, implantes medicos) | 1–1,000 | 150–600 |

| Sinterización directa por láser de metales (DMLS) | Polvo sinterizado por láser (densidad ligeramente menor que SLM: 98–99%) | Prototipos y piezas de bajo volumen. (p.ej., componentes de prueba automotrices) | 1–500 | 120–500 |

| Fusión por haz de electrones (MBE) | Haz de electrones derrite el polvo (más rápido que SLM, mejor para piezas grandes) | Grandes piezas aeroespaciales (p.ej., palas de turbina) | 1–100 | 400–1200 |

| Chorro de aglutinante | El aglutinante pega el polvo para darle forma (luego sinterizado para densificar) | Alto volumen, piezas de bajo costo (p.ej., bienes de consumo, soportes industriales) | 1,000+ | 80–300 |

| Fabricación híbrida | Combina la impresión 3D con el mecanizado para lograr tolerancias ultra ajustadas | Partes críticas (p.ej., implantes medicos, componentes de motores aeroespaciales) | 1–200 | 200–800 |

Cada técnica tiene ventajas únicas: nuestro equipo le ayuda a elegir la mejor según el tamaño de su pieza., necesidades de fuerza, y presupuesto.

Estudios de caso: Impresión 3D de aluminio en acción

Nuestro Estudios de casos de impresión 3D de aluminio mostrar cómo hemos ayudado a los clientes a superar desafíos y lograr mejores resultados que los métodos tradicionales:

Estudio de caso 1: Soporte de ala aeroespacial

- Cliente: Un fabricante líder de aviones.

- Desafío: Reducir el peso de un soporte de ala (soporte de acero tradicional pesaba 2,2 kg, aumento del consumo de combustible) manteniendo la fuerza.

- Solución: Aluminio impreso SLM 7075 soporte con estructura de celosía, optimizado para peso y capacidad de carga.

- Resultados:

- 60% reducción de peso (0.88kg frente a. 2.2kilos).

- La resistencia a la tracción aumentó en 15% (650 MPa frente a. de acero 560 MPa).

- 40% ahorro de costos vs.. mecanizado (no se necesitan herramientas).

Estudio de caso 2: Carcasa de batería para vehículos eléctricos

- Cliente: Una puesta en marcha de vehículos eléctricos.

- Desafío: Desarrollar un peso ligero, Carcasa de batería resistente a la corrosión que se adapta a las dimensiones reducidas del vehículo. (Las piezas fundidas de aluminio tradicionales eran demasiado voluminosas.).

- Solución: Aluminio impreso DMLS 6061 carcasa con canales de refrigeración integrados (para disipar el calor).

- Resultados:

- 30% reducción de peso frente a. aluminio fundido.

- 25% aumento de la autonomía de la batería (debido al peso más ligero).

- Plazo de entrega reducido a 2 semanas (vs. 6 semanas para el casting).

Estudio de caso 3: Implante ortopédico médico

- Cliente: Una empresa de dispositivos médicos.

- Desafío: Cree una placa ósea específica para el paciente que sea liviana y biocompatible (traditional titanium plates were heavy for patients).

- Solución: SLM-printed medical-grade aluminum 1050 plate—customized from patient CT scans with porous surfaces to promote bone growth.

- Resultados:

- 40% reducción de peso frente a. titanium.

- 98% patient comfort rating (vs. 85% para titanio).

Cumple con ISO 10993 estándares de biocompatibilidad.

¿Por qué elegirnos?: Your Trusted Aluminum 3D Printing Partner

Con tantos proveedores de impresión 3D, here’s why Yigu Technology stands out for Impresión 3D de aluminio:

- Pericia: Nuestros ingenieros tienen 6+ years of experience with aluminum—we know how to optimize parameters (p.ej., potencia del láser, tratamiento térmico) to avoid common issues like porosity or warping, ensuring every part meets your performance standards. We also hold certifications in aerospace (AS9100) y médico (ISO 13485) fabricación, so you can trust us with even the most critical projects.

- Innovación: Nos mantenemos a la vanguardia de las tendencias de la industria, such as new aluminum alloys (p.ej., high-temperature Al-Cu-Mg alloys for aerospace underhood parts) and advanced printing techniques (p.ej., multi-material aluminum-carbon fiber printing for ultra-lightweight components). invertimos 15% of our annual budget in R&D to bring you the latest in aluminum 3D printing technology.

- Atención al cliente: Nuestro equipo está disponible 24/7 para responder preguntas, provide project updates, and resolve issues. From your first design consultation to post-delivery follow-up, we prioritize clear communication—we even assign a dedicated project manager to every client to ensure your needs are met.

- Productos de calidad: Nunca escatimamos esfuerzos en calidad. Every aluminum part undergoes 100% inspección (X-ray CT scans, CMM measurements, prueba de tracción) to ensure it meets your specs and industry standards. Our quality rate is 99.7%—meaning only 3 out of 1,000 parts require rework.

Precios competitivos: Ofrecemos transparente, cost-effective pricing with no hidden fees. By optimizing our workflow (p.ej., recycling unused aluminum powder to reduce waste) and leveraging economies of scale for high-volume orders, we pass savings on to you. We also provide free cost estimates—just share your CAD model, and we’ll give you a detailed quote within 24 horas.