Our Digital Light Processing (DLP) 3D Printing Services

Discover how Digital Light Processing (DLP) 3D Printing is revolutionizing additive manufacturing—combining ultra-fast UV curing with pinpoint precision printing to turn complex designs into high-quality parts, from rapid prototypes to industrial-scale production. Whether you’re in medical, automotive, or jewelry, DLP technology delivers unmatched layer-by-layer fabrication and design flexibility.

What is DLP 3D Printing?

Digital Light Processing (DLP) 3D Printing is an additive manufacturing technology that uses photopolymerization to build objects layer by layer. Unlike traditional methods, DLP cures entire layers of photopolymer resin at once using a digital light projector, enabling faster speeds and finer details.

At its core, DLP relies on UV curing—a process where ultraviolet light triggers a chemical reaction, hardening resin into solid shapes. This makes it ideal for applications requiring precision printing, such as dental crowns or intricate jewelry pieces.

Our DLP 3D Printing Capabilities

At Yigu Technology, we leverage DLP’s strengths to meet diverse industry needs. Below is a breakdown of our key capabilities:

| Capability | Description | Typical Use Case |

| High-Resolution Printing | Achieves layer thicknesses as low as 10μm for sharp, detailed parts. | Medical implants, micro-electronics |

| Rapid Prototyping | Produces functional prototypes in hours (vs. days with traditional methods). | Product design iterations |

| Industrial-Scale Production | Scales to high-volume runs with consistent quality. | Automotive components, consumer goods |

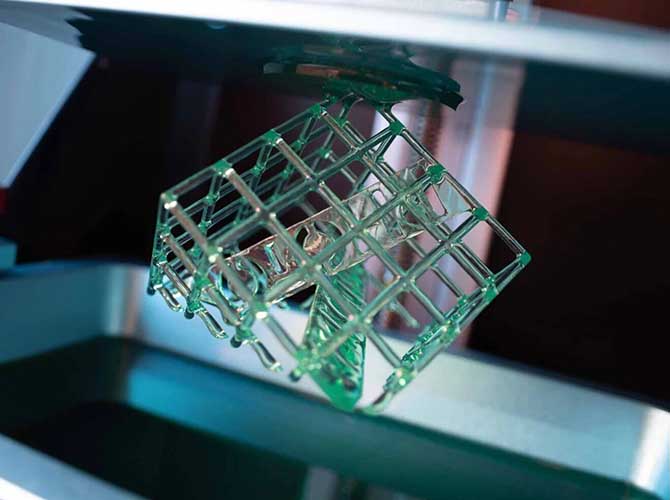

| Complex Geometries | Prints undercuts, hollow structures, and lattice designs with ease. | Aerospace parts, custom tooling |

| Multi-Material Printing | Combines resins (e.g., flexible + rigid) in a single print for versatile parts. | Wearable tech, prosthetics |

The DLP 3D Printing Process

DLP printing follows a streamlined, repeatable workflow—from design to finished part. Here’s a step-by-step breakdown:

- Pre-Processing:

Start with a 3D model (usually in STL format). Our team uses advanced slicing software to split the model into thin layers (0.01–0.1mm) and add support structures if needed.

- Printing:

The printer’s build plate lowers into a vat of photopolymer resin. A digital light projector shines UV light onto the resin surface, curing one full layer at a time. The build plate then lifts slightly, and the process repeats.

- Post-Processing:

After printing, parts undergo support removal (manual or automated) and cleaning (using isopropyl alcohol to remove uncured resin). For enhanced durability, some parts are post-cured with additional UV light.

DLP 3D Printing Materials

We offer a wide range of photopolymer resins tailored to specific applications. Each resin type delivers unique properties, from flexibility to high-temperature resistance:

| Material Type | Key Properties | Industry Application |

| Engineering Resins | High strength, impact resistance | Automotive parts, tooling |

| Dental Resins | Biocompatible, tooth-colored | Crowns, bridges, aligner molds |

| Medical Resins | FDA-approved, sterilizable | Surgical guides, implants |

| Casting Resins | Low ash content, easy burnout | Jewelry casting, metal prototypes |

| Flexible Resins | Elastic, tear-resistant | Wearables, gaskets |

| High-Temperature Resins | Withstands up to 250°C (482°F) | Aerospace components, electronics |

Surface Treatment for DLP Parts

To enhance aesthetics, durability, or functionality, we offer a range of surface finishing options for DLP-printed parts:

- Sanding: Smoothes layer lines using fine-grit sandpaper (120–2000 grit).

- Polishing: Creates a glossy finish with compounds (e.g., carnauba wax).

- Painting: Applies acrylic or spray paints for color matching or branding.

- Coating: Adds protective layers (e.g., epoxy, PTFE) for chemical resistance.

- Electroplating: Plates parts with metal (e.g., nickel, gold) for conductivity or luxury appeal.

Anodizing: Treats aluminum-coated parts to improve corrosion resistance and color options.

Tolerances: Precision You Can Trust

DLP 3D printing excels at dimensional accuracy—critical for parts that need to fit or perform precisely. Our tolerance capabilities are outlined below:

| Tolerance Metric | Typical Range | Advantage |

| Dimensional Accuracy | ±0.1mm (for parts up to 100mm) | Ensures parts fit with other components |

| Layer Thickness | 10–100μm | Finer layers = smoother surfaces |

| Feature Resolution | Down to 50μm (e.g., tiny holes, threads) | Enables micro-scale details |

| Repeatability | <0.05mm variation across 100+ prints | Consistent quality for production |

These tight tolerances make DLP ideal for medical devices (e.g., surgical tools) and aerospace parts, where even small deviations can cause failure.

Key Advantages of DLP 3D Printing

Compared to other 3D printing technologies (e.g., FDM, SLA), DLP offers unique benefits:

- Fast Printing Speed: Cures entire layers at once—up to 5x faster than SLA for large parts.

- High Detail: Delivers smoother surfaces and finer features than FDM, with no visible layer lines.

- Cost-Effective: Low material waste (only uses resin needed for the part) and lower labor costs for production runs.

- Design Flexibility: Prints complex shapes that are impossible with CNC machining or injection molding.

Rapid Iteration: Allows designers to test and refine prototypes in days, accelerating time-to-market.

DLP 3D Printing Applications by Industry

DLP technology is transforming industries worldwide. Here’s how different sectors use it:

| Industry | Common Applications | Benefit to Industry |

| Medical | Surgical guides, implants, prosthetics | Biocompatible parts, fast turnaround |

| Dental | Crowns, bridges, aligner trays | Custom fits, same-day production |

| Automotive | Prototypes, interior components, tooling | Reduces development time, lightweights parts |

| Aerospace | Lattice structures, engine components | High strength-to-weight ratio |

| Jewelry | Intricate pendants, ring prototypes | Fine details, easy casting |

| Electronics | Micro-components, sensor housings | Precision for small, complex parts |

DLP vs. Other Manufacturing Techniques

How does DLP stack up against other additive manufacturing methods? The table below compares key metrics:

| Technique | Speed | Resolution | Material Range | Best For |

| DLP | Fast (layer-wide curing) | High (10–50μm) | Photopolymers | Detailed parts, rapid prototyping |

| Stereolithography (SLA) | Slow (point-by-point) | High (25–100μm) | Photopolymers | Smooth prototypes, medical parts |

| Masked SLA (mSLA) | Fast | High | Photopolymers | Consumer-grade 3D printing |

| Continuous Liquid Interface Production (CLIP) | Very Fast | Medium | Photopolymers | High-volume production |

| FDM | Slow | Low (100–500μm) | Plastics (PLA, ABS) | Functional prototypes, low-cost parts |

Why Choose Yigu Technology for DLP 3D Printing?

At Yigu Technology, we don’t just offer DLP printing—we deliver end-to-end solutions tailored to your needs. Here’s what sets us apart:

- Expertise: Our team has 10+ years of experience in DLP and additive manufacturing, ensuring optimal results for every project.

- Quality Assurance: We use ISO-certified resins and rigorous testing (e.g., dimensional checks, strength tests) to guarantee part quality.

- Fast Turnaround: Prototypes are ready in 24–48 hours; production runs ship within 5–7 days.

- Customer Support: Dedicated engineers work with you from design to delivery, solving issues and optimizing prints.

Competitive Pricing: Transparent pricing with no hidden fees—even for small-batch or custom projects.