Metal Die Casting Service

Yigu Technology specialize in delivering high – quality metal die – casting components with exceptional technical precision. Our state – of – the – art processes ensure rapid production cycles, enabling us to provide reliable on – time delivery. From the initial prototype stage to full – scale mass production, we leverage our advanced technologies and expertise to cast your success in metal – faster, smarter, and better. We are committed to offering these superior components at competitive costs, ensuring that our clients receive the best value for their investment.

Our Metal Die Casting Capability

Yigu Technology is a leading provider of die casting solutions, including HPDC, LPDC, Squeeze and so on, equipped with over 30 advanced machines to ensure unparalleled quality and efficiency. Our state – of – the – art facility holds certifications such as ISO 9001,, which attest to our strict adherence to the highest industry standards. We excel in high – precision, high – volume production across diverse sectors, including automotive and medical applications, with stringent quality control measures in place.

Our industry – leading die casting technology specializes in precision components made from aluminum, magnesium, and zinc alloys. Here are the key highlights of our competitive edge:

- Ultra – Tight Tolerances: We achieve tolerances as tight as ±0.02mm, meeting the most demanding requirements for automotive, electronics, and medical applications.

- High – Volume Production: Our fully automated production lines ensure rapid turnaround times, enabling us to meet tight deadlines without compromising on quality.

- End – to – End Control: We offer integrated services that cover the entire production process, from mold design to post – processing, giving us complete control over the quality and consistency of our products.

- Material Expertise: We have in – depth knowledge of custom alloys, allowing us to create lightweight, corrosion – resistant, and high – strength components tailored to your specific needs.

Partner with Yigu Technology for reliable, sustainable, and cost – effective die casting services that consistently exceed expectations.

Cold Chamber

Cold chamber die casting injects molten metal into a mold under high pressure for precise, high-strength metal parts.

Hot Chamber

Hot chamber die casting melts and injects metal quickly, ideal for low-melting alloys like zinc, ensuring fast, efficient production.

Vacuum-Assisted

Vacuum-assisted die casting removes air from the mold cavity, reducing porosity and improving metal flow for higher-quality, dense castings.

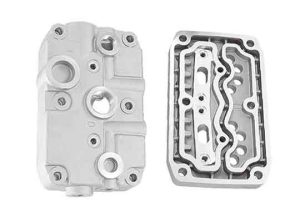

Metal Die Casting Parts Display

The products displayed below have been approved by the customer, and we strictly abide by the confidentiality agreement.

Our Die-Casting Material Options

Die Casting uses a huge range of metal, making it ideal for many applications across nearly every industry.

Our die casting technology level

In the realm of die-casting, the evaluation of performance metrics is crucial for gauging efficiency, quality, and cost-effectiveness. The key performance indicators include cycle time, defect rate, dimensional accuracy, surface finish, and tooling life.

Our die-casting solutions are designed with advanced capabilities to meet the most demanding requirements. The max clamping force of our machines reaches an impressive 2500T, ensuring robust and reliable molding processes. We can achieve a min wall thickness of 0.5mm, which is ideal for creating lightweight yet strong components. Additionally, our standard surface finish is Ra1.6μm, with the option for post-machining to enhance it to Ra0.8μm, providing a superior finish that meets the highest standards of quality.

Complete Your Die-Casting And Manufacturing Process in 5 steps

Why Choose Yigu Metal Die Casting?

At Yigu Technology, we specialize in the production of high-precision and durable die-cast components. Our state-of-the-art technology and rigorous quality control processes ensure that our products deliver flawless performance in demanding industries such as automotive, aerospace, and industrial manufacturing.

Each component we produce adheres to global standards, guaranteeing reliability and cost-effectiveness. By partnering with Yigu Technology, you gain access to custom solutions tailored to your specific needs, all backed by our dedication to excellence.

Advantages of Die Casting

High-Precision Manufacturing: Our advanced die-casting technology ensures tight tolerances (±0.05mm), making it ideal for complex geometries while significantly reducing the need for secondary machining.

Lightweight Material Expertise: We have proven capabilities in die casting with aluminum and magnesium alloys, achieving the perfect balance between strength and weight reduction. This is particularly beneficial for applications in the automotive and electronics industries.

High-Volume Production Efficiency: Our automated production lines enable fast and large-scale deliveries at reduced costs, making us the ideal choice for meeting mass production demands.

Die Casting Applications

Automotive: We specialize in manufacturing critical components such as engine housings, transmission parts, and EV battery trays, ensuring durability and precision for the automotive industry.

Electronics: Our expertise extends to the electronics sector, where we produce 5G heat sinks, smartphone frames, and connectors, delivering high-performance solutions for modern technology.

Medical: In the medical field, we manufacture surgical instrument components and imaging device parts, maintaining the highest standards of quality and reliability for critical applications.