When creating mold replication models—whether for industrial prototypes, artistic statues, or functional parts—choosing the right material directly impacts the model’s accuracy, Haltbarkeit, und Kosten. This article breaks down the most widely used materials for mold replication models, ihre Schlüsselmerkmale, Anwendungsszenarien, and step-by-step operation methods to help you make the optimal choice.

1. Core Materials for Mold Replication Models: At-a-Glance Comparison

To quickly evaluate which material fits your project, start with this comprehensive comparison table. It highlights each material’s advantages, Einschränkungen, and typical uses—saving you time in preliminary selection.

| Material | Kernvorteile | Schlüsselbeschränkungen | Typical Replication Model Applications |

| Silikon | Hochtemperaturwiderstand, Korrosionsbeständigkeit, starker Tränenwiderstand, high replication precision | Higher cost than gypsum; requires ratio mixing | Mannequins, mechanische Teile, Autoteile, silicone dolls, figure prototypes |

| Gypsum | Niedrige Kosten, simple operation, Einfache Reinigung, high rigidity/hardness | Poor impact resistance; low temperature tolerance | Silicone model shells, simple decorative replicas, low-precision structural supports |

| Harz (Unsaturated/Epoxy) | Hohe Stärke, hohe Zähigkeit, Resistenz tragen, Korrosionsbeständigkeit, hohe Präzision | Longer curing time; Giftige Dämpfe (without proper ventilation) | High-end figures, statues, detailed auto parts, industrial prototypes |

| Hot Melt Adhesive | Strong toughness, good shape retention, bendable without damage | Geringe Hitzebeständigkeit; limited precision for fine details | Small decorative replicas, temporäre Prototypen, low-stress functional parts |

2. Detailed Breakdown of Each Replication Material

Below is an in-depth analysis of each material, using a “trait + Betrieb + scenario” structure to link technical features to real-world use cases. This helps you understand Warum Und Wie to use each material for your model.

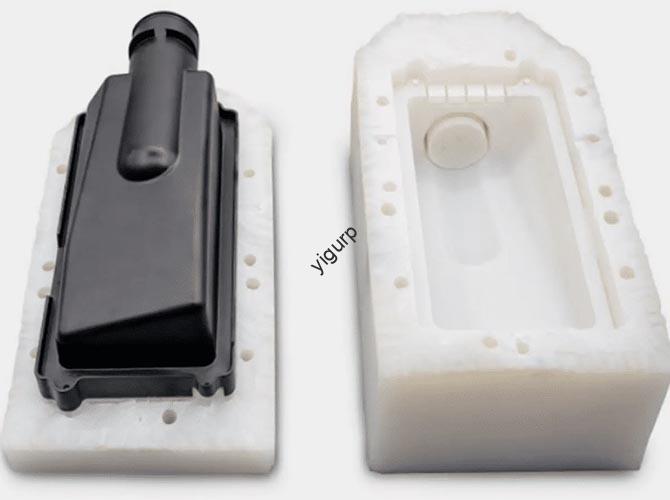

2.1 Silikon: The Precision Choice for High-Detail Replicas

Warum ist es Silikon a top pick for mold replication models? Its four unrivaled traits make it ideal for capturing fine details:

- High replication precision: Silicone can replicate even tiny surface textures (Z.B., 0.1mm grooves on a mechanical part) ohne Verzerrung. This is critical for making accurate auto part prototypes or figure prototypes, where detail fidelity directly affects the model’s usability.

- Extreme durability: Mit Hochtemperaturwiderstand (up to 200–300°C depending on grade) Und Korrosionsbeständigkeit, silicone models withstand harsh environments—perfect for testing industrial parts that may encounter heat or chemicals.

- Strong tear resistance: Unlike fragile materials like gypsum, silicone models won’t tear easily during demolding or handling, reducing waste in production.

How to Use Silicone for Replication:

- Prepare two components of silicone (usually labeled A and B) and mix them in a 1:1 Verhältnis (check the product manual for exact proportions).

- Add the recommended amount of curing agent and stir thoroughly to avoid air bubbles.

- Pour the mixture into the prepared mold cavity, ensuring it covers all details.

- Wait for the silicone to cure (typically 4–8 hours at room temperature; faster with heat).

Gemeinsame Szenarien: Industrial mechanical part prototypes, high-end silicone dolls, life-sized mannequins, detailed auto part replicas.

2.2 Gypsum: The Budget-Friendly Option for Simple Replicas

Gypsum shines when cost and ease of use are priorities. Its key benefits address the needs of beginners or low-budget projects:

- Niedrige Kosten: Gypsum powder is significantly cheaper than silicone or resin, making it ideal for large-scale but low-precision models (Z.B., a 1m-tall decorative statue shell).

- Easy operation: No complex ratio mixing or special equipment is needed—even those new to mold replication can master it quickly.

- Strong structural support: Its high rigidity and hardness make it perfect for creating shells for silicone models (Z.B., a gypsum outer shell to reinforce a soft silicone mannequin).

How to Use Gypsum for Replication:

- Mix gypsum powder and clean water in a 2:1 Verhältnis (nach Gewicht) to form a smooth paste (adjust consistency if needed—too thin = longer drying; too thick = air bubbles).

- Press the original model into the gypsum paste gently, ensuring the paste covers the model’s surface evenly.

- Let the gypsum dry completely (6–12 hours at room temperature; avoid direct sunlight to prevent cracking).

- Carefully remove the original model to reveal the gypsum replication mold.

Gemeinsame Szenarien: Silicone model outer shells, simple decorative replicas (Z.B., small statues), school project prototypes.

2.3 Harz: The Durable Choice for High-Performance Models

Harz (including unsaturated resin and epoxy resin) is the go-to for replication models that need strength and precision. Its standout traits include:

- High mechanical performance: Resin models have hohe Stärke Und Zähigkeit, making them suitable for functional prototypes (Z.B., a test version of an auto part that needs to withstand pressure).

- Wear and corrosion resistance: Unlike gypsum, resin models won’t chip easily or degrade when exposed to mild chemicals—ideal for long-term use or outdoor displays (mit richtiger Beschichtung).

- Vielseitigkeit: Different resin types serve different needs:

- Unsaturated resin: Faster curing (1–2 Stunden) und niedrigere Kosten, good for general-purpose replicas.

- Epoxidharz: Higher precision and stronger bonding, perfect for high-end figures or industrial parts requiring tight tolerances.

How to Use Resin for Replication:

- For unsaturated/epoxy resin, mix the two components (A = resin, B = hardener) in the recommended ratio (normalerweise 10:1 for unsaturated, 2:1 for epoxy).

- Stir the mixture slowly to avoid creating air bubbles (use a vacuum chamber if available for high-precision models).

- Pour the resin into the mold and let it cure (unsaturated resin: 1–2 Stunden; Epoxidharz: 4–6 Stunden).

- Demold and sand the surface for a smooth finish if needed.

Gemeinsame Szenarien: High-end collectible figures, detailed statues, industrial auto part prototypes, corrosion-resistant mechanical components.

2.4 Hot Melt Adhesive: The Quick-Fix for Small, Flexible Replicas

Hot melt adhesive is a practical choice for small-scale or temporary mold replication models. Its key advantages are:

- Schnelle Turnaround: No curing time—just heat, gießen, and cool (10–15 minutes total), making it great for urgent prototype needs.

- Strong shape retention: Einmal abgekühlt, hot melt adhesive models maintain their shape and can be bent hard without breaking—ideal for parts that need minor flexibility (Z.B., a small toy component).

- Low cost and accessibility: Hot melt adhesive sticks are cheap and widely available at hardware stores, no specialized materials required.

How to Use Hot Melt Adhesive for Replication:

- Heat a hot melt adhesive gun until the adhesive is fully melted (typically 150–180°C).

- Slowly squeeze the melted adhesive into the mold cavity, filling all gaps without overpouring.

- Let the adhesive cool to room temperature (5–10 Minuten) until it hardens.

- Gently remove the model from the mold—no additional curing steps needed.

Gemeinsame Szenarien: Small decorative replicas (Z.B., keychain charms), temporary prototypes for design testing, low-stress toy parts.

3. Yigu Technology’s View on Materials for Mold Replication Models

Bei Yigu Technology, we believe the best material for mold replication models depends on three factors: project precision needs, Budget, and end-use environment. For high-detail industrial parts, silicone or epoxy resin is unbeatable; for low-cost simple shells, gypsum works best; for small urgent projects, hot melt adhesive saves time. We always advise clients to test a small sample first—this avoids wasting materials and ensures the model meets expectations. Zusätzlich, we’re seeing a trend toward eco-friendly variants (Z.B., water-based silicone, low-VOC resin) to reduce environmental impact, which we actively promote for sustainable replication projects.

4. FAQ: Common Questions About Materials for Mold Replication Models

Q1: Can I use silicone to replicate a model that needs to withstand high temperatures (Z.B., a small engine part)?

Ja! High-temperature silicone (grade 300°C+) is designed for this scenario. It retains its shape and toughness even at elevated temperatures, making it suitable for replicating heat-exposed parts like small engine components.

Q2: Is gypsum suitable for making detailed figure prototypes?

NEIN. Gypsum has low replication precision and poor impact resistance—it cannot capture fine details (Z.B., facial features on a figure) and is prone to chipping. For detailed figures, use silicone or epoxy resin instead.

Q3: Do I need safety equipment when using resin for mold replication models?

Ja. Harz (especially unsaturated resin) releases toxic fumes during mixing and curing. Always work in a well-ventilated area, wear nitrile gloves to protect your hands, and use a face mask to avoid inhaling fumes.