Hochtemperatur-Silikonstopfen sind spezielle Elastomerkomponenten, die extremer Hitze standhalten und gleichzeitig Öffnungen abdichten oder schützen (z.B., Löcher, Threads) im Industriebereich, medizinisch, und lebensmittelbezogene Anwendungen. Made from high-purity silicone rubber blended with heat-resistant additives, Sie behalten ihre Elastizität und strukturelle Integrität auch bei Temperaturen bei, die weit über denen von Standard-Silikonprodukten liegen. But what sets them apart from regular silicone plugs, how are they made, and how do you choose the right one?

1. Key Characteristics: Why High-Temperature Silicone Plugs Excel

High-temperature silicone plugs outperform standard silicone plugs and other sealing materials (z.B., Gummi, Plastik) in four critical areas. The table below highlights their unique advantages:

| Merkmal | High-Temperature Silicone Plugs | Standard Silicone Plugs | Rubber/Plastic Plugs |

| Temperaturbeständigkeit | Hält stand 200–350°C (kurzfristig: 350°C für 2 Std.); no cracking or hardening | Only tolerates up to 150°C; deforms above 180°C | Melts or brittle at 80–120°C |

| Physical Durability | Zugfestigkeit: 3–8MPa; Bruchdehnung: >400%; no permanent deformation after compression | Zugfestigkeit: 2–5MPa; Verlängerung: <300%; prone to set after repeated use | Low tensile strength (<2MPa); cracks easily with friction |

| Chemical Stability | Beständig gegen Säuren (pH-Wert 2–12), Alkalien, Öle, und Lösungsmittel; no corrosion or swelling | Limited resistance to strong acids/alkalis; swells in oil | Dissolves or degrades in most chemicals |

| Safety Compliance | Food-grade variants meet FDA/GB standards; medical-grade options are biocompatible (no tissue irritation) | Rarely food/medical certified; may contain harmful additives | Often non-toxic but not suitable for food/medical contact |

2. Materialien & Manufacturing Process: Building Heat Resistance

The performance of high-temperature silicone plugs starts with material selection and strict production control. Below is a linear breakdown of the key steps:

Schritt 1: Material Blending (The Foundation of Heat Resistance)

- Base Silicone: Verwenden fumed silica gel (high purity, low impurity content) as the base—this boosts density and heat resistance compared to precipitated silica.

- Additive Integration: Mix in specialized additives:

- Heat stabilizers (z.B., Eisenoxid) to prevent thermal oxidation at 300°C+.

- Antioxidants to extend aging resistance (service life: 5+ years in high-heat environments).

- For food/medical grades: Add non-toxic plasticizers (no phthalates) to maintain flexibility.

Schritt 2: Formen (Shaping for Precision)

Choose a molding method based on the plug’s shape and volume:

- Formpressen: Ideal for high-volume standard shapes (z.B., blind hole plugs). Heat silicone compound in a mold (160–180°C) under pressure (10–20MPa) to form the plug.

- Extrusion Molding: Used for long, cylindrical plugs (z.B., through-hole types). Push silicone through a die, then cut to length after cooling.

Schritt 3: Vulcanization (Locking in Performance)

- Primary Vulcanization: Cure the molded plug in an oven (180–200°C) for 5–10 minutes to set the basic shape.

- Secondary Vulcanization: Post-cure at 200–220°C for 2–4 hours to remove volatile by-products. This step critical—without it, the plug may lose heat resistance over time.

Schritt 4: Quality Testing

- Check Temperaturbeständigkeit: Expose samples to 350°C for 2 Std.; ensure no deformation or hardness change.

- Verifizieren Maßhaltigkeit: Use calipers to confirm diameter (±0.1mm tolerance for precision plugs).

- For food/medical grades: Conduct toxicity tests (no heavy metals, no VOCs).

3. Anwendungen nach Branchen: Where Heat Resistance Matters

High-temperature silicone plugs solve unique problems across sectors. Here’s how they’re used in key industries:

| Industrie | Typical Use Cases | Recommended Plug Type | Hauptvorteile |

| Industrielle Fertigung | – Protecting screw holes/process holes during high-temperature spraying (250°C+) or electroplating.- Sealing communication cabinet through-holes to prevent dust/chemical ingress. | Countersunk thread type (for threaded holes); large-diameter plugs (25–50mm for big process holes) | Resists paint/chemicals; wiederverwendbar (bis zu 50 times) |

| Medizinische Geräte | – Sealing medicine bottle necks (prevents drug contamination).- Protecting medical instrument ports during autoclave sterilization (134°C, Hochdruck). | Small-diameter blind hole plugs (3–10mm); medical-grade silicone | Biokompatibel; withstands repeated sterilization |

| Lebensmittelverarbeitung | – Sealing food can lids (maintains freshness).- Covering baking mold holes (prevents batter leakage during oven heating, 220°C). | Food-grade transparent plugs; heat-resistant up to 250°C | Ungiftig; leicht zu reinigen (spülmaschinenfest) |

| Scientific Research | – Sealing laboratory flasks/test tubes during high-temperature experiments (z.B., distillation at 200°C).- Protecting sensor ports in environmental chambers (Temperaturwechsel: -40°C bis 300 °C). | Heat-resistant through-hole plugs; flexible variants (for irregular openings) | Withstands extreme temperature swings; ensures airtight seals |

4. Spezifikation & Shape Guide: Choose the Right Fit

Selecting the wrong size or shape leads to leaks or damage. Use this table to match plugs to your needs:

| Specification/ Shape | Key Details | Ideal für |

| Durchmesser (Common Sizes) | – Klein: 3–10mm (medical bottles, Reagenzgläser)- Medium: 11–20mm (industrial process holes)- Groß: 21–50mm (automotive/communication cabinets) | Choose based on the hole’s inner diameter (add 0.5–1mm for a tight seal) |

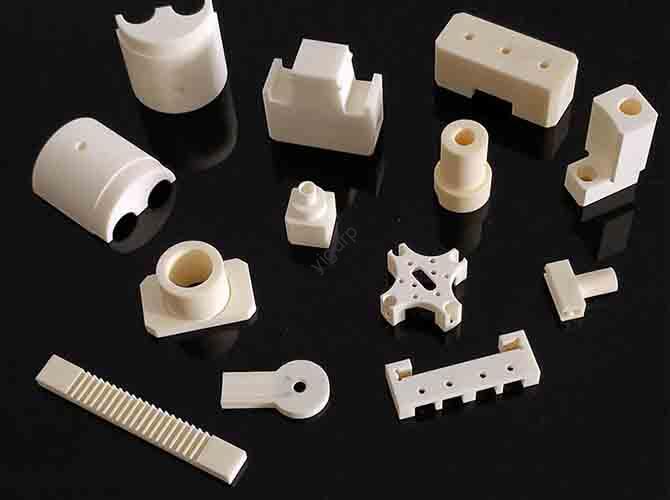

| Shape Types | – Through-Hole Type: Hollow center; fits holes that need to be penetrated (z.B., sensor wires).- Blind Hole Type: Solid bottom; seals one-end closed holes (z.B., medicine bottle necks).- Countersunk Thread Type: Has a recessed top; fits countersunk threaded holes (z.B., Maschinenteile). | Through-hole: Wire/cable pass-throughsBlind hole: Full sealing needsCountersunk: Threaded hole protection |

5. Yigu Technology’s Perspective on High-Temperature Silicone Plugs

Bei Yigu Technology, we see high-temperature silicone plugs as “heat-resistant guardians” for critical components. Für Industriekunden, unser countersunk thread plugs reduce rework rates by 60% during high-temperature spraying—they stay in place even at 300°C and leave no residue. For medical partners, unser FDA-certified blind hole plugs unterziehen 100+ autoclave cycles without losing flexibility, ensuring drug safety.

Looking ahead, we’ll focus on two innovations: 1) Developing ultra-high-temperature plugs (up to 400°C) for aerospace applications, Und 2) Creating custom shapes (z.B., irregular holes) with 3D printing technology to reduce lead time by 30%. Our goal is to make high-temperature silicone plugs more adaptable to extreme and niche scenarios.

FAQ

- How to clean and reuse high-temperature silicone plugs?

For industrial plugs: Wipe with a solvent (z.B., isopropyl alcohol) to remove paint/chemicals; avoid sharp tools that scratch the surface. For food/medical plugs: Wash with warm soapy water or autoclave (134°C). Most plugs can be reused 30–50 times if no cracks or deformation occur.

- Can high-temperature silicone plugs be used in low-temperature environments?

Yes—they maintain flexibility from -60°C bis 350 °C. This makes them ideal for applications with temperature swings (z.B., outdoor industrial equipment that faces cold nights and hot days).

- What’s the difference between food-grade and industrial-grade high-temperature silicone plugs?

Food-grade plugs use non-toxic additives (no heavy metals/VOCs) and meet FDA/GB food safety standards; they’re safe for direct food contact. Industrial-grade plugs may contain cost-effective additives (z.B., carbon black for UV resistance) that are not food-safe—never use them in food processing.