Gasunterstützter Druckguss (GADC) ist ein revolutionärer Fortschritt in der Metallumformung, der wesentliche Einschränkungen des traditionellen Druckgusses beseitigt. By integrating high-pressure inert gas (typischerweise Stickstoff) in den Gießprozess ein, Es entstehen Hohlstrukturen oder funktionale Kanäle innerhalb von Teilen – was neue Möglichkeiten für den Leichtbau eröffnet, Komplex, und Hochleistungskomponenten. Für Hersteller, die mit Materialverschwendung zu kämpfen haben, Designbeschränkungen, or defect issues in traditional die casting, GADC offers a game-changing solution. This article breaks down its principles, Vorteile, Anwendungen, and practical implementation to help you leverage this technology effectively.

1. Core Principles of Gas-Assisted Die Casting: Wie es funktioniert

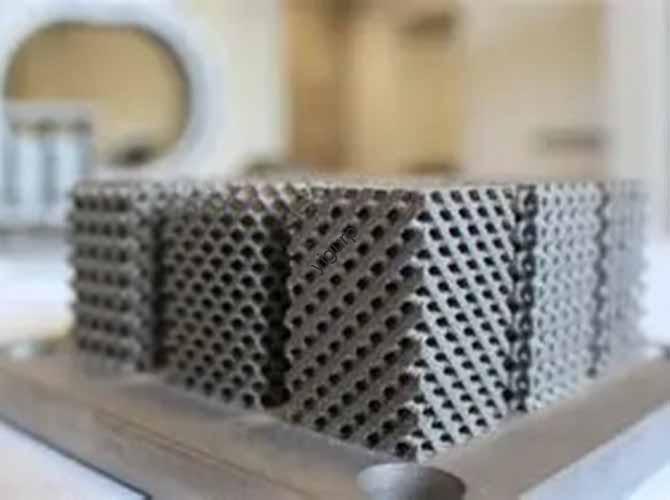

To understand GADC’s value, it’s first critical to grasp its operational mechanism. Im Gegensatz zum herkömmlichen Druckguss (which fills the mold cavity entirely with molten metal), GADC uses gas to “Form” the part from the inside out. Below is a linear, step-by-step breakdown of its key processes, paired with a comparison to traditional methods.

1.1 Key Process Stages

GADC follows four sequential steps, each requiring precise control to ensure quality:

- Melt Dosing & Filling: Similar to traditional die casting, a measured amount of molten metal (z.B., aluminum or magnesium alloy) is injected into the mold cavity. The goal here is partial filling—only enough metal to form a solid outer shell (typically 2-5mm thick, abhängig von der Teilegröße).

- Gas Injection Timing Control: This is the “make-or-break” Schritt. High-pressure inert gas (bis zu 500 Bar) is injected into the cavity nach the molten metal forms a stable surface shell. If injected too early, gas will mix with the metal and cause pores; if too late, the metal will solidify completely, and gas cannot displace it. Sensors monitor mold temperature and metal solidification progress to trigger gas injection at the optimal moment.

- Secondary Chamber Pressure Relief & Extrusion: The gas pushes the remaining molten metal (not yet solidified) into a pre-designed secondary cavity (oder “overflow reservoir”). The gas pressure is maintained throughout this stage to compress the metal shell, minimizing shrinkage and ensuring dimensional accuracy.

- Nachbearbeitung: Once the part solidifies, Die Form öffnet sich, and the casting is removed. Excess material from the secondary cavity is trimmed off, and the internal gas channel is inspected for smoothness (critical for applications like cooling systems).

1.2 GADC vs. Traditional Die Casting: A Comparative Overview

The table below highlights the fundamental differences between GADC and traditional die casting, emphasizing why GADC outperforms in key areas:

| Aspect | Traditional Die Casting | Gas-Assisted Die Casting |

| Materialverbrauch | Fills the entire cavity; high material consumption (15-30% waste from excess metal) | Verwendungsmöglichkeiten 10-40% less metal (only forms an outer shell); minimaler Abfall |

| Designflexibilität | Limited to solid or simple hollow parts (requires removable cores for holes) | Enables complex internal channels (z.B., Kühlkanäle) and thin-walled structures without cores |

| Fehlerrate | Prone to shrinkage holes and porosity (due to full cavity filling and uneven cooling) | Reduces defects by 60-80%: gas pressure eliminates shrinkage; no core-related gaps |

| Part Weight | Heavier (solid structure) | 15-35% leichter (hollow design) – ideal for lightweighting needs (z.B., Elektrofahrzeuge) |

| Nachbearbeitung | Extensive machining to remove excess material and fix surface defects | Minimal trimming (only secondary cavity waste); smoother surfaces reduce machining needs |

2. Technical Characteristics of GADC: What Makes It Reliable

GADC’s success hinges on three technical features that ensure consistency and adaptability—critical for industrial-scale production. These characteristics use a 总分 structure, starting with an overview and diving into details.

2.1 High-Precision Real-Time Control

GADC relies on advanced sensor technology to monitor three key parameters continuously:

- Formtemperatur: Maintained at 180-250°C (for aluminum alloys) to ensure uniform shell formation.

- Internal Cavity Pressure: Tracks gas pressure and metal flow to prevent over-pressurization (which causes mold damage) or under-pressurization (which leads to incomplete hollowing).

- Gas Injection Path: Ensures gas flows evenly through the cavity, avoiding localized pressure spikes that could crack the metal shell.

This control reduces process variability, keeping defect rates below 2% (im Vergleich zu 5-10% in traditional die casting).

2.2 Modular System Design

GADC systems are built with interchangeable modules, making them adaptable to different part sizes and materials:

- Gas Injection Module: Delivers inert gas at adjustable pressures (50-500 Bar) to match part requirements (z.B., 300 bar for thick-walled automotive parts, 100 bar for thin electronic components).

- Gate Valve Module: Controls the flow of molten metal into the secondary cavity, preventing backflow.

- Central Control Unit (z.B., MAGIT Module): Integrates data from all sensors, supporting multi-channel independent control for complex parts with multiple gas injection points.

This modularity means manufacturers can upgrade existing die casting machines to GADC with minimal investment.

2.3 Strong Material Adaptability

GADC works seamlessly with light metals commonly used in high-demand industries:

- Aluminiumlegierungen (z.B., ADC12, A380): The most popular choice—GADC reduces their weight while maintaining strength, ideal for automotive and aerospace parts.

- Magnesiumlegierungen (z.B., AZ91D): Noch leichter als Aluminium; GADC’s gas pressure prevents magnesium’s tendency to form shrinkage defects.

- Zinklegierungen (z.B., Belastungen 5): Used for small, Präzise Teile (z.B., Elektronikgehäuse); GADC enables thinner walls (down to 1mm) without deformation.

3. Core Advantages of GADC: Solving Traditional Die Casting Pain Points

GADC’s value lies in its ability to address four major challenges manufacturers face with traditional methods. Each advantage uses a problem-solution structure to highlight practical benefits.

3.1 Increased Design Freedom

Problem: Traditional die casting cannot create complex internal structures (z.B., integrated cooling ducts) without removable cores—these cores add cost, increase defect risk, and limit part geometry.

Lösung: GADC uses gas to form hollow channels directly, eliminating the need for cores. Zum Beispiel, an automotive motor housing that previously required 3 separate components (housing + cooling pipe + bracket) can now be manufactured as a single part with integrated ducts. This reduces assembly steps by 70% and eliminates welding-related quality issues.

3.2 Material & Kostenoptimierung

Problem: Traditional die casting wastes 15-30% of metal on excess material (z.B., Läufer, overflow). Molds with cores are also more expensive to design and maintain.

Lösung: GADC reduces material consumption by 10-40% (via hollowing) and cuts mold costs by 20-30% (no cores). For a manufacturer producing 100,000 aluminum EV battery frames annually, this translates to savings of ~$200,000 in material costs alone. Zusätzlich, lighter parts reduce shipping costs by 15-25%.

3.3 Enhanced Part Performance

Problem: Traditional solid castings have uneven cooling, leading to inconsistent mechanical properties. They also lack built-in functional features (z.B., heat dissipation channels).

Lösung: GADC’s gas pressure creates a uniform metal shell with:

- Improved Stiffness & Stärke: Reinforced rib layouts (enabled by hollow design) increase bending strength by 25-40%.

- Better Heat Dissipation: Integrated cooling channels reduce part temperature by 30-50% in high-heat applications (z.B., power electronic components).

- Leakage Resistance: Glatt, uniform internal airways (no core gaps) make GADC parts ideal for pressure-bearing applications (z.B., hydraulische Ventile).

3.4 Improved Quality & Maßgenauigkeit

Problem: Traditional die casting suffers from shrinkage holes, Porosität, and surface defects—these require costly rework or scrapping.

Lösung: GADC’s gas pressure compresses the metal shell, eliminating shrinkage and porosity. Oberflächenrauheit (Ra) is reduced to 1.6-3.2 μm (im Vergleich zu 3.2-6.3 μm in traditional casting), meeting strict automotive and aerospace surface standards. Dimensional tolerance is also improved: GADC parts maintain ±0.1mm accuracy for parts up to 500mm in length.

4. Typical Application Areas of GADC: Where It Adds the Most Value

GADC excels in industries where lightweighting, Komplexität, und Leistung sind entscheidend. Below are three key sectors with Beispiele aus der Praxis to illustrate practical use cases.

4.1 New Energy Vehicles (NEVs)

NEVs demand lightweight, high-strength parts to extend battery range. GADC is used for:

- Motorgehäuse: Integrated cooling ducts reduce motor temperature by 40%, extending its lifespan by 50%.

- Battery Packs: Hollow frames reduce weight by 30% while maintaining crash resistance (meeting ISO 26262 Sicherheitsstandards).

- Lightweight Frames: GADC’s thin-walled structures (1.5-2mm) cut frame weight by 25%, improving vehicle energy efficiency.

4.2 Elektronikindustrie

Electronic devices require small, precise parts with heat management capabilities. GADC is ideal for:

- High-Heat Dissipation Enclosures: z.B., 5G base station housings—integrated gas channels dissipate heat 3x faster than solid aluminum enclosures.

- Power Electronic Components: z.B., inverter modules for EV chargers—GADC’s low porosity ensures electrical insulation (no leakage risks).

- Thin-Walled Housings: z.B., laptop chassis—GADC enables 1mm-thick magnesium alloy walls that are 20% lighter than plastic, with better durability.

4.3 Luft- und Raumfahrt

Aerospace parts need to be lightweight yet ultra-strong. GADC is used for:

- High-Strength Structural Parts: z.B., aircraft seat frames—GADC’s aluminum-magnesium alloy parts weigh 35% less than traditional steel frames.

- Fluid Control Valves: Smooth internal channels (no core gaps) ensure precise fluid flow, critical for fuel or hydraulic systems.

- Satellitenkomponenten: Lightweight GADC parts reduce launch costs (every 1kg saved cuts launch expenses by ~$10,000).

5. Yigu Technology’s Perspective on Gas-Assisted Die Casting

Bei Yigu Technology, we see GADC as a cornerstone of the “leicht, high-efficiency” manufacturing trend—especially for NEVs and aerospace. Many manufacturers hesitate to adopt GADC due to concerns about process complexity, but the reality is that modern modular systems (like those with MAGIT modules) make it accessible even for mid-sized factories.

We recommend a phased approach: start with simple parts (z.B., Elektronikgehäuse) to master gas injection timing and pressure control, then scale to complex components (z.B., motor housings). CAE simulation is also critical—we help clients use simulation tools to predict gas flow and optimize mold design, reducing trial-and-error costs by 40%.

Letztlich, GADC is not just a technology upgrade—it’s a strategic investment. As industries demand lighter, effizientere Teile, manufacturers who adopt GADC early will gain a competitive edge in cost, Qualität, und Designflexibilität.

6. FAQ: Common Questions About Gas-Assisted Die Casting

Q1: Is gas-assisted die casting suitable for small-batch production?

Ja, but it’s most cost-effective for medium-to-large batches (10,000+ parts/year) due to initial mold and system investment. Für kleine Chargen, we recommend retrofitting existing die casting machines with modular GADC kits (instead of buying new equipment) to lower costs.

Q2: What type of gas is used in GADC, and is it safe?

High-purity nitrogen (99.999%) is the standard—It’s inert, so it won’t react with molten metal (avoiding oxidation or contamination). Nitrogen is also non-toxic and recyclable, making GADC environmentally friendly. No safety risks are associated with gas use if the system is properly maintained (z.B., checking for leaks).

Q3: Can GADC be used to repair defective traditional die castings?

NEIN, GADC is a preventive manufacturing technology, not a repair method. It eliminates defects (z.B., Porosität, Schwindung) during production, rather than fixing them after. For defective traditional castings, repair is often costly—switching to GADC is a better long-term solution to avoid defects entirely.