In der heutigen schnelllebigen Fertigungsindustrie, speed matters—especially when it comes toCNC machining prototypes. Egal, ob Sie ein Startup sind, das ein neues Produktdesign testet, oder ein großer Hersteller, der eine Komponente validiert, Wenn Sie wissen, wie lange die Herstellung Ihres Prototyps dauern wird, können Sie Zeitpläne planen, Kosten senken, und der Konkurrenz immer einen Schritt voraus sein. Die Wahrheit ist, Es gibt keine allgemeingültige Antwort: CNC machining prototype speed ranges from a few days to a few weeks, depending on four critical factors. This article breaks down each factor, shares real examples, and gives tips to speed up your prototype process.

1. Design Complexity: The Bigger the Challenge, the Longer the Time

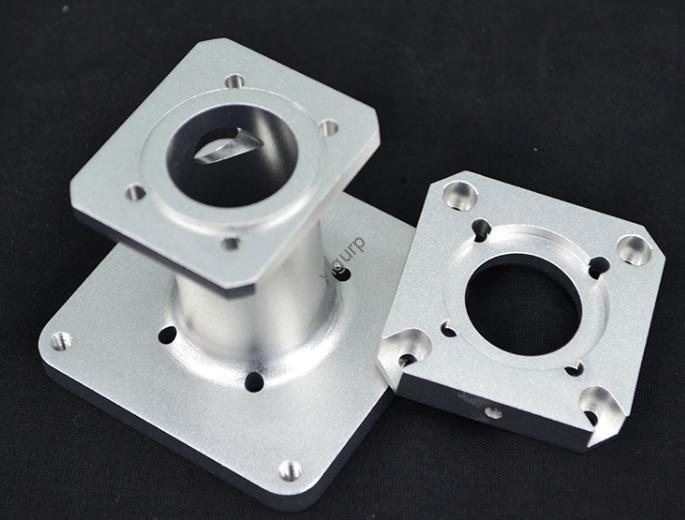

Design complexity is one of the biggest drivers ofCNC machining prototype speed. A simple, flat part will be ready in days, while a design with intricate details or complex surfaces can take weeks. Here’s why:

CNC machines work from pre-programmed paths—every curve, hole, and texture needs a precise code. Complex designs require more programming time (to map each detail) and more machine setup steps (to switch tools or adjust angles). Zum Beispiel:

- A basic plastic bracket (mit 2 holes and a flat surface) needs 1–2 hours of programming and 3–4 hours of machining.

- A complex robotic arm component (with curved edges, innere Hohlräume, Und 10+ kleine Löcher) needs 8–10 hours of programming and 15–20 hours of machining.

Real-World Example

A medical device startup needed a prototype for a tiny surgical tool (10cm long) with a serrated edge and 3 Mikrolöcher (0.5mm Durchmesser). The complex design required 6 hours of programming (to ensure the holes were perfectly aligned) Und 12 hours of machining (to avoid damaging the delicate serrations). The total prototype time was 3 Tage – im Vergleich zu 1 day for a simple tool without micro-holes.

2. Materialauswahl: Harder Materials Slow Things Down

The material you choose directly impacts how fast yourCNC machining prototype is made. Verschiedene Materialien haben einzigartige Eigenschaften (Härte, Verschleißfestigkeit, cutting difficulty) that change machining speed. Here’s a breakdown of common materials and their typical prototype timelines:

| Materialtyp | Härte (Rockwell Scale) | Bearbeitungsgeschwindigkeit (mm/min) | Typical Prototype Time (Simple Part) | Typical Prototype Time (Complex Part) |

|---|---|---|---|---|

| PMMA (Acryl) | R65–R70 | 300–500 | 1–2 Tage | 3–4 Tage |

| Aluminiumlegierung 6061 | B95–B100 | 200–400 | 2–3 Tage | 4–5 Tage |

| Edelstahl 304 | B70–B80 | 100–200 | 3–4 Tage | 6–7 Tage |

| Titanlegierung | C30–C35 | 50–100 | 5–6 Tage | 8–10 Tage |

Why This Happens

Harder materials like stainless steel or titanium require slower cutting speeds (to prevent tool wear) and more frequent tool changes (to keep cuts precise). Zum Beispiel, machining a stainless steel part at 150 mm/min takes twice as long as machining an aluminum part at 300 mm/min. Soft materials like PMMA are easier to cut—they don’t dull tools quickly, so the machine can run faster.

Real-World Example

An automotive company tested two prototypes for a car dashboard clip: one in aluminum (6061) and one in stainless steel (304). The aluminum clip took 2 days to make (fast cutting speed, no tool changes). The stainless steel clip took 4 days—workers had to slow the machine to 180 mm/min and change the cutting tool 3 times (because the steel dulled it).

3. Machining Method: CNC vs. Handmade—Speed vs. Präzision

The machining method you pick also affectsCNC machining prototype speed. While CNC machining is precise, it needs setup and programming time. Handmade prototypes are faster for simple parts but lack the precision of CNC. So vergleichen sie sich:

| Machining Method | Einrichtungszeit | Programming Time | Bearbeitungsgeschwindigkeit (Simple Part) | Präzision (Toleranz) | Am besten für |

|---|---|---|---|---|---|

| CNC-Bearbeitung | 1–2 Stunden | 1–8 Stunden | 3–20 hours | ±0.01–±0.1 mm | Komplex, hochpräzise Teile |

| Handmade | 15–30 mins | 0 Std. | 1–5 hours | ±0.1–±0.5 mm | Einfach, low-precision parts |

Key Tradeoff

Handmade prototypes are faster for simple designs—for example, a wooden handle can be made in 2 hours by hand, vs. 5 Stunden mit CNC (including setup and programming). But for parts that need precision (like a gear with tight tolerances), CNC is worth the wait. CNC also has better repeatability—if you need 5 identical prototypes, CNC can make them in the same time as 1, while handmade parts will take 5x longer (and may not be identical).

Real-World Example

A consumer goods brand needed 10 prototypes of a plastic bottle cap. They tried both methods:

- Handmade: 2 hours per cap (gesamt 20 Std., 2.5 Tage). Aber 3 caps were too loose (tolerance ±0.3 mm) and couldn’t fit the bottle.

- CNC-Bearbeitung: 1 hour of setup, 2 hours of programming, Und 0.5 hours per cap (gesamt 8.5 Std., 1 Tag). Alle 10 caps had a tolerance of ±0.05 mm and fit perfectly.

4. Number of Samples: Small Batches Are Faster (But Not Always More Efficient)

The number of prototypes you need (sample count) impacts speed, but not in the way you might think. Kleine Chargen (1–5 samples) are faster to start, but larger batches (10–20 samples) can be more efficient per part. Here’s why:

- Kleine Chargen (1–5 samples): You only need to program and set up the machine once, then run the parts one after another. Eine Menge 2 aluminum brackets takes 3 Tage (same as 1 bracket, since setup/programming is only done once).

- Große Chargen (10–20 samples): The setup and programming time is spread across more parts. Eine Menge 10 aluminum brackets takes 4 days—so per part, es ist 0.4 Tage vs. 1.5 days for a batch of 2. But if you only need 2, there’s no point in making 10 (it wastes material and time).

Real-World Example

A robotics startup needed either 3 oder 10 prototypes of a motor mount. Here’s the timeline for both:

- 3 Prototypen: 1 day of setup/programming, 2 days of machining (gesamt 3 Tage). Kosten: $300 (Material + Arbeit).

- 10 Prototypen: 1 day of setup/programming, 3 days of machining (gesamt 4 Tage). Kosten: $800 (Material + Arbeit).

The startup chose 3 prototypes—they saved 1 day and $500, and didn’t need extra parts cluttering their workshop.

3 Tips to Speed Up Your CNC Machining Prototype

Now that you know the factors, here are practical tips to cut down yourCNC machining prototype Zeit:

- Simplify the Design (Where Possible): Remove non-essential details. Zum Beispiel, if a part doesn’t need a decorative texture, skip it—this can cut programming time by 30%.

- Choose the Right Material: Pick a material that balances your needs (Stärke, Aussehen) with speed. If you don’t need stainless steel’s durability, use aluminum—it’s 2x faster to machine.

- Work with an Experienced Provider: A skilled CNC shop can optimize programming and setup. Zum Beispiel, Yigu Technology’s team once cut a client’s prototype time from 5 Tage bis 3 days by adjusting tool paths (to avoid unnecessary steps).

Yigu Technology’s View on CNC Machining Prototype Speed

Bei Yigu Technology, we believeCNC machining prototype speed should never come at the cost of quality. Many clients rush to pick the fastest method (like handmade) only to end up with flawed parts that need rework. We recommend starting with a clear design (simplify where you can) and choosing a material that fits your timeline—aluminum or PMMA for fast prototypes, stainless steel for durable ones. Our team uses optimized programming tools to cut setup time by 20%, and we always test small batches first to avoid delays. Zum Beispiel, we helped a startup get a complex robotic component prototype in 4 Tage (vs. der Branchendurchschnitt von 6 Tage) by streamlining tool changes.

FAQ

- What’s the fastest a CNC machining prototype can be made?

For a simple part (z.B., a flat aluminum bracket with 2 Löcher) using a soft material like aluminum or PMMA, you can get a prototype in 1–2 days. Dazu gehört 1 hour of programming, 1 hour of setup, and 2–3 hours of machining. - Why does a complex CNC prototype take longer than a simple one?

Complex designs need more programming (to map every detail, like micro-holes or curved surfaces) and more machine time (to switch tools, adjust angles, or avoid damaging delicate features). A complex part can take 3–4x longer than a simple one—for example, a robotic arm component takes 5 Tage vs. 1 day for a bracket. - Can I speed up a CNC prototype if I need it urgently?

Ja! Ask your CNC provider about “rush options”: they may prioritize your order, use faster-cutting tools, or simplify non-critical design details. Zum Beispiel, a stainless steel part that normally takes 4 days can be ready in 3 days with a rush—though this may add 20–30% to the cost. Just make sure to communicate your priorities (speed vs. kosten) clearly.