In today’s fast-paced industrial manufacturing world, finding technologies that balancehohe Präzision, fast speed, Undenvironmental friendliness ist der Schlüssel, um wettbewerbsfähig zu bleiben. The laser cutting process stands out as an advanced solution, leveraging a high-energy-density laser beam to punch and cut materials with remarkable accuracy. Egal, Möbel, or aerospace manufacturing, understanding the core features of laser cutting can help you solve pain points like low machining efficiency, poor cut quality, and high tool maintenance costs. Unten, we break down the critical features of laser cutting in detail, mit echten Daten, Beispiele, und praktische Erkenntnisse.

1. Exceptional High Cutting Quality: Meeting Strict Precision Requirements

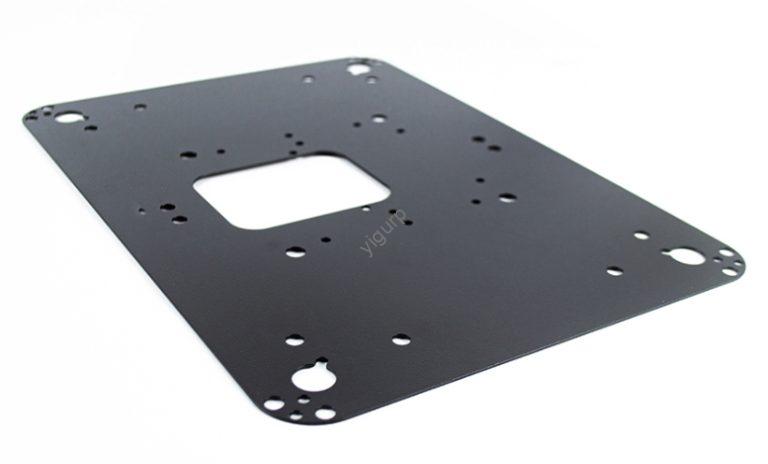

One of the most significant advantages of laser cutting is itshigh cutting quality—a game-changer for industries where dimensional accuracy and surface finish are non-negotiable. This quality stems from two key factors: the laser’s small spot size and concentrated energy.

- Eng, uniform kerf: The laser’s focused energy creates a narrow kerf (the width of the cut), ensuring the two sides of the incision remain parallel and perpendicular to the material surface. This eliminates the need for secondary finishing, saving time and labor.

- Superior dimensional accuracy: The process achieves a dimensional accuracy of ± 0,05 mm—critical for parts like automotive components, Medizinprodukte, or electronic enclosures where even tiny deviations can cause assembly failures.

- Smooth cut surface & minimal deformation: The laser’s localized heat input results in a smooth cut surface (often requiring no sanding or polishing) and a minimal Wärme-betroffene Zone (Gefahr). A small HAZ means the material around the cut doesn’t warp or lose structural strength, which is essential for thin materials like aluminum sheets or delicate composites.

Beispiel für reale Welt: A manufacturer of aerospace parts uses laser cutting to produce titanium alloy brackets. The ±0.05mm accuracy ensures the brackets fit perfectly with other components, while the minimal HAZ preserves the titanium’s high strength—avoiding costly rejections or safety risks.

2. Fast Cutting Speed: Dramatically Improving Machining Efficiency

Speed is a top priority for manufacturers looking to scale production, and laser cutting delivers impressiveSchnelle Schnittgeschwindigkeit that outperforms traditional methods like mechanical sawing or plasma cutting. The speed varies by laser power and material type, but even mid-range lasers offer significant efficiency gains.

To illustrate, here’s a comparison of cutting speeds for common materials using a 1200W laser (a popular power level for industrial use):

| Materialtyp | Materialstärke | Schnittgeschwindigkeit (1200W Laser) |

|---|---|---|

| Mild steel plate | 2mm | 600 cm/min |

| Polypropylene resin sheet | 5mm | 1200 cm/min |

| Aluminum alloy sheet | 3mm | 450 cm/min |

| Leather (for upholstery) | 1mm | 1800 cm/min |

Praktische Auswirkungen: A furniture manufacturer switching from mechanical cutting to laser cutting for 5mm polypropylene resin sheets saw their production rate triple—from 400 sheets per day to 1200 sheets per day. This not only reduced lead times for clients but also allowed the factory to take on more orders without adding extra shifts.

3. Non-Contact Cutting: Reducing Maintenance & Umweltauswirkungen

Im Gegensatz zu herkömmlichen Schneidwerkzeugen (Z.B., Sah Klingen, Fräser) that touch the workpiece, laser cutting uses anon-contact cutting method—where the laser torch never makes physical contact with the material. This feature solves two major industry challenges: tool wear and environmental pollution.

- No tool wear: Since there’s no physical contact, there’s no need to replace worn-out blades or bits. This cuts down on maintenance costs (Z.B., no monthly tool replacement budgets) and reduces downtime for tool changes. For a manufacturer cutting 10,000 metal parts monthly, this can save up to $5,000 annually in tool expenses.

- Low noise & Vibration: Laser cutting operates at noise levels below 70 decibels (similar to a normal conversation), making it safer for workers and reducing the need for soundproofing. The lack of vibration also protects delicate workpieces (like thin glass or plastic) from damage.

- Eco-friendly operation: The process produces no dust, Chips, or harmful fumes (when paired with proper ventilation), meeting strict environmental regulations. This is especially important for industries like food packaging or medical device manufacturing, where cleanliness is mandatory.

4. Großes Anwendungsbereich: Cutting Almost Any Material

Laser cutting’s versatility makes it suitable forvarious metal and non-metal materials, making it a one-stop solution for diverse manufacturing needs. Jedoch, it’s important to note that a material’s thermophysical properties (Z.B., Schmelzpunkt, Wärmeleitfähigkeit) Undlaser absorption rate can affect cutting results—so choosing the right laser type (Z.B., fiber laser for metals, CO₂ laser for non-metals) ist Schlüssel.

Common Materials for Laser Cutting

| Materialkategorie | Beispiele | Typical Industry Uses |

|---|---|---|

| Metalle | Weichstahl, Aluminium, Kupfer, Titan | Kfz -Teile, Luft- und Raumfahrtkomponenten, Hardware |

| Non-metals | Leather, Holz, Papier, fiber | Furniture upholstery, Verpackung, textile cutting |

| Verbundwerkstoffe | Metal matrix composites (Mmcs), Kohlefaser | High-performance parts for drones, Rennwagen |

| Polymere | Polypropylen, Acryl, PVC | Beschilderung, Plastikgehäuse, medizinische Tabletts |

Fallstudie: A textile manufacturer uses a CO₂ laser cutter to cut intricate patterns into cotton and polyester fibers. Unlike traditional die-cutting, laser cutting allows for quick design changes (no need to make new dies) and produces clean edges that don’t fray—reducing material waste by 20%.

5. Key Auxiliary Systems: Ensuring Consistent Quality for Large-Format Cutting

For large-format laser cutting (Z.B., cutting 3m x 6m metal sheets), two auxiliary systems work with the laser to maintain quality: Diefollower system Undauxiliary gas.

- Follower system: This system automatically adjusts the cutting head’s height to keep it highly consistent with the material surface—even if the material has slight warping or unevenness. Zum Beispiel, when cutting a large aluminum sheet that’s slightly bowed, the follower system ensures the laser remains at the optimal distance, preventing uneven cuts or burn marks.

- Auxiliary gas: A stream of gas (usually oxygen, Stickstoff, or compressed air) is blown through the cutting head. Its roles include: 1) Blowing away molten slag (Trümmer) from the kerf to keep the cut clean; 2) Cooling the machined surface to reduce the HAZ; 3) Protecting the focusing lens from contamination by slag or fumes. Zum Beispiel, using nitrogen gas when cutting stainless steel prevents oxidation (Rost) on the cut surface, eliminating the need for post-cut cleaning.

Die Perspektive der Yigu -Technologie zum Laserschnitt

Bei Yigu Technology, we recognize that laser cutting is more than just a machining process—it’s a driver of industrial innovation. Its combination of high quality, Geschwindigkeit, and versatility aligns with the needs of modern manufacturers seeking to reduce costs and improve competitiveness. We focus on optimizing auxiliary systems (like intelligent follower systems and gas flow control) to help clients maximize laser cutting efficiency, whether they’re working with thin metals or thick composites. By integrating laser cutting with smart manufacturing tools, we aim to make precision and sustainability accessible to more industries.

(FAQ)

1. What is the maximum material thickness laser cutting can handle?

The maximum thickness depends on laser power and material type. A 1200W laser can cut up to 8mm mild steel or 5mm aluminum, while a 6000W high-power laser can handle 25mm mild steel. For non-metals like wood, a CO₂ laser can cut up to 50mm thick boards.

2. Does laser cutting require a lot of operator training?

No—modern laser cutting machines are user-friendly with intuitive software. Most operators can learn basic operation in 1–2 weeks, and advanced features (like design optimization) take 1–2 months to master. Manufacturers also offer training support to ensure safe, efficient use.

3. Is laser cutting cost-effective for small-batch production?

Yes—unlike traditional methods that require expensive tooling (Z.B., dies for stamping), laser cutting has no upfront tool costs. This makes it ideal for small batches (even 1–10 parts) because you only pay for material and machine time. For small-batch projects, laser cutting can reduce costs by 30–50% compared to mechanical cutting.