If you’re searching for reliable die casting solutions in Europe, Slovakia stands out as a top-tier destination. With its strategic location at the heart of the continent, skilled workforce, and deep integration into the automotive and manufacturing supply chains, Slovakia offers high-quality Aluminium -Sterben, Zinkstirsche, and precision engineering services that meet global standards. Whether you’re a small business or a large multinational, partnering with Slovak die casting providers can streamline your production, Kosten senken, and ensure consistent part quality—all key reasons why the country has become a hub for European die casting needs.

Why Choose Die Casting in Slovakia? Key Industry Advantages

Slovakia’s die casting sector isn’t just successful by chance; it’s built on a foundation of unique advantages that address the most common pain points of manufacturers. Let’s break down the factors that make it a competitive choice:

Strategic Geographical Location

Slovakia’s position in Central Europe is a game-changer for logistics. It shares borders with Austria, Hungary, Polen, the Czech Republic, and Ukraine, putting it within a 1,000-kilometer radius of major European markets like Germany, Frankreich, and Italy. For companies in the automotive industry—Slovakia’s largest manufacturing sector—this means faster delivery times. Zum Beispiel, a die casting supplier in Bratislava can ship aluminum auto components to a German automaker’s assembly plant in under 24 Std., cutting down on inventory costs and supply chain delays. This proximity also simplifies face-to-face meetings with suppliers, a critical factor for projects requiring tight collaboration.

Skilled Workforce and Technical Expertise

Slovakia has a long history of manufacturing excellence, dating back to its industrial heritage in the former Czechoslovakia. Heute, the country invests heavily in technical education, with vocational schools and universities (such as the Slovak University of Technology in Bratislava) offering specialized programs in metallurgy, tool design, Und advanced manufacturing. This focus ensures a steady pipeline of skilled workers: according to the Slovak Automotive Industry Association (ZAP), über 35% of the country’s manufacturing workforce has specialized training in engineering or technical fields—well above the European average of 28%.

A real-world example is a medium-sized die casting firm in Košice, which partners with local vocational schools to run apprenticeship programs. These programs train students in CNC machining and die casting process optimization, was zu a 20% lower error rate in their production lines compared to industry benchmarks.

Cost Competitiveness Without Quality Compromise

While Western European countries like Germany or Switzerland offer top-tier die casting, they often come with higher labor and operational costs. Slovakia bridges this gap: labor costs in the country’s manufacturing sector are approximately 40% lower than in Germany (data from Eurostat, 2024) , but the quality of work remains on par. This is because Slovak die casting companies adhere to strict international standards, einschließlich ISO 9001 for quality management and IATF 16949 for automotive-specific requirements.

One multinational client in the electronics industry reported saving 18% on their zinc die casting components after switching to a Slovak supplier, without any reduction in part precision (tolerances remained at ±0.05mm).

Key Die Casting Processes and Materials Used in Slovakia

Slovak die casting providers specialize in the two most widely used processes: Heiße Kammerstirbsguss Und Kaltkammer -Sterblichkeitsguss. Each is tailored to specific materials and part requirements, ensuring optimal results for different applications.

Heiße Kammerstirbsguss

Ideal for materials with low melting points, wie zum Beispiel Zink Und Magnesium, hot chamber die casting is a fast, effizienter Prozess. In this method, the injection system is submerged in the molten metal, allowing for quick cycle times (often 15–30 seconds per part). This makes it perfect for high-volume production of small to medium-sized parts, like electronic enclosures, automotive hardware, or consumer goods components.

A leading Slovak supplier in Žilina uses hot chamber die casting to produce 500,000 zinc alloy brackets monthly for a European white goods manufacturer. The process’s speed and consistency have helped the client meet peak demand during holiday seasons without delays.

Kaltkammer -Sterblichkeitsguss

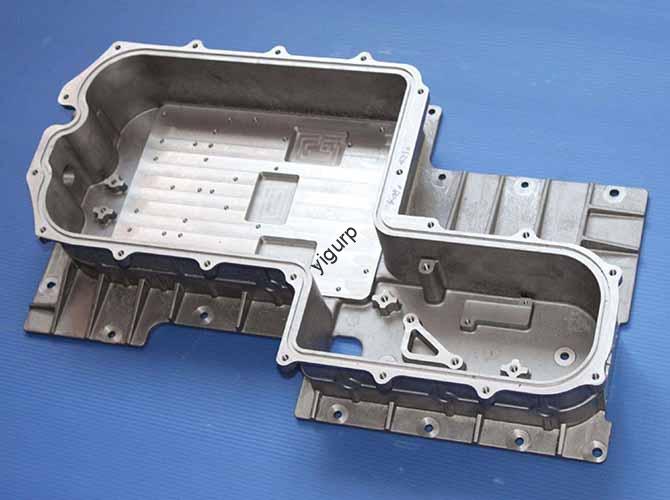

For materials with higher melting points—primarily Aluminium (the most popular die casting material globally)—cold chamber die casting is the standard. In this process, molten aluminum is poured into a separate chamber before being injected into the die. While cycle times are slightly longer (20–45 seconds per part), cold chamber die casting can handle larger, more complex parts, such as automotive engine blocks, Übertragungsgehäuse, und strukturelle Komponenten.

Aluminum die casting dominates Slovakia’s market, Berücksichtigung 65% of all die casting production (Quelle: Slovak Die Casting Association, 2024) . This is driven by the automotive industry’s shift toward lightweight materials to improve fuel efficiency; aluminum parts are 30% lighter than steel equivalents while maintaining strength.

Materialvergleich: Zinc vs. Aluminum in Slovak Die Casting

To help you choose the right material for your project, here’s a side-by-side comparison of the two most common die casting materials used in Slovakia:

| Besonderheit | Zinkstirsche | Aluminium -Sterben |

| Schmelzpunkt | Niedrig (419° C) – faster heating/cooling | Hoch (660° C) – requires more energy |

| Stärke | Good for small, tragende Teile | Higher tensile strength – ideal for large, Struktureile |

| Gewicht | Schwerer (Dichte: 7.14 g/cm³) | Leicht (Dichte: 2.7 g/cm³) |

| Korrosionsbeständigkeit | Moderate – may need coating | High – naturally forms protective oxide layer |

| Kosten | Higher material cost | Lower material cost (more abundant) |

| Typische Anwendungen | Elektronische Teile, Hardware, Kleine Komponenten | Automobilgehäuse, Motorteile, large structural components |

Top Die Casting Suppliers and Clusters in Slovakia

Slovakia’s die casting industry is concentrated in several key regions, each with a focus on specific sectors. These clusters make it easy to find suppliers that align with your needs, whether you’re in automotive, Elektronik, oder industrielle Fertigung.

Major Industry Clusters

- Bratislava Region: As Slovakia’s capital and largest city, Bratislava is home to multinational die casting companies and Tier 1 automotive suppliers. Many firms here specialize in high-precision aluminum die casting for luxury car brands (Z.B., Volkswagen, BMW, which have assembly plants nearby). Zum Beispiel, a Bratislava-based supplier produces aluminum chassis components for BMW’s electric vehicles, leveraging the city’s proximity to the automaker’s local factory.

- Košice Region: Located in eastern Slovakia, Košice is a hub for medium-sized die casting firms that serve both automotive and industrial clients. The region’s 优势 lies in its skilled workforce and lower operational costs compared to Bratislava. A Košice supplier specializes in zinc die casting for agricultural machinery, working with clients like John Deere to produce corrosion-resistant parts for farm equipment.

- Žilina Region: In northern Slovakia, Žilina focuses on Magnesium -Würfelguss—a niche but growing segment. Magnesium is even lighter than aluminum, making it ideal for aerospace and high-performance automotive parts. A Žilina-based company partners with European aerospace firms to produce magnesium brackets for aircraft interiors, adhering to strict aerospace quality standards (AS9100).

How to Evaluate a Slovak Die Casting Supplier

When choosing a supplier, look beyond just price. Consider these key factors:

- Zertifizierungen: Ensure they hold ISO 9001 (Qualität) und iatf 16949 (Automobil) Zertifizierungen. For aerospace projects, check for AS9100.

- In-House Capabilities: Do they offer post-casting services like machining, fertig, oder Montage? This can reduce lead times and costs.

- Qualitätskontrollprozesse: Ask about their testing methods—e.g., dimensional inspection with CMM (Koordinatenmessmaschinen), or non-destructive testing (Ndt) für kritische Teile.

- Sustainability Practices: Many Slovak suppliers are investing in eco-friendly processes, such as recycling scrap metal (most reuse 95% aus Aluminiumschrott) and reducing energy consumption.

Trends Shaping Slovakia’s Die Casting Industry in 2024 and Beyond

The Slovak die casting sector is constantly evolving to meet global demands for sustainability, Präzision, und Effizienz. Here are the top trends to watch:

Nachhaltigkeit und Kreislaufwirtschaft

Slovakia’s die casting companies are leading the way in eco-friendly manufacturing. The industry’s focus on the circular economy includes:

- Scrap Metal Recycling: Aluminum and zinc are highly recyclable, and Slovak suppliers typically reuse 90–95% of their production scrap. This not only reduces waste but also lowers material costs—recycled aluminum requires 95% less energy to produce than primary aluminum (Quelle: International Aluminum Institute) .

- Energieeffizienz: Many firms are upgrading their facilities with energy-efficient furnaces and LED lighting. A supplier in Nitra, Zum Beispiel, installed solar panels to power 30% of its die casting operations, cutting its carbon footprint by 25%.

- Eco-Friendly Coatings: To reduce environmental impact, suppliers are moving away from toxic coatings and adopting water-based or powder coatings for die cast parts.

Automatisierung und Industrie 4.0 Integration

Automation is transforming die casting in Slovakia, improving precision and reducing labor costs. Key technologies include:

- Robotic Process Automation (RPA): Robots are used for tasks like part removal, Trimmen, und Inspektion, Reduzierung des menschlichen Fehlers. A Bratislava supplier implemented robotic inspection for its aluminum auto parts, increasing quality control efficiency by 40%.

- IoT-Enabled Machines: Die casting machines equipped with IoT sensors monitor temperature, Druck, and cycle times in real time. This data is used to optimize processes—for example, adjusting pressure to reduce defects—resulting in a 15% improvement in yield rates.

- Digital Twins: Some forward-thinking suppliers use digital twins (virtual replicas of production lines) to simulate and test new die designs before physical production. This cuts down on trial-and-error and shortens time-to-market for new parts.

Growth in Electric Vehicle (Ev) Komponenten

As Europe shifts to electric vehicles, Slovakia’s die casting industry is adapting to meet the demand for EV-specific parts. These include:

- Battery Housings: Aluminum die casting is ideal for EV battery housings, as it provides strength to protect the battery while remaining lightweight. Slovak suppliers are partnering with automakers like Volkswagen (which has an EV factory in Bratislava) to produce these critical components.

- Electric Motor Parts: Precision zinc and aluminum die casting are used for motor housings and connectors, which require tight tolerances to ensure optimal performance. According to ZAP, EV-related die casting orders in Slovakia increased by 35% In 2023, and this trend is expected to continue through 2030.

Yigu Technology’s Perspective on Die Casting in Slovakia

Bei Yigu Technology, we recognize Slovakia as a standout player in the European die casting landscape—one that balances quality, kosten, and innovation effectively. What sets Slovakia apart is its ability to adapt to global manufacturing trends, especially the shift toward sustainability and EV production. Unlike some other European countries, Slovakia offers a “middle ground” of competitiveness: it has the technical expertise to meet strict automotive and aerospace standards, yet its costs are more accessible than Western Europe.

We’ve seen clients benefit significantly from partnering with Slovak suppliers, particularly in terms of supply chain resilience. Die zentrale Lage der Slowakei verringert die Abhängigkeit von entfernten Lieferanten (Z.B., in Asien) und minimiert Versandverzögerungen – ein entscheidender Vorteil im heutigen volatilen Logistikumfeld. Zusätzlich, Der Fokus des Landes auf die Ausbildung von Arbeitskräften stellt sicher, dass Lieferanten komplexe Projekte bewältigen können, von großvolumigen Aluminium-Autoteilen bis hin zu Präzisions-Magnesium-Luft- und Raumfahrtkomponenten.

Für Unternehmen, die ihre europäische Produktionspräsenz erweitern möchten, Der slowakische Druckgusssektor ist eine strategische Entscheidung. It’s not just about getting parts made—it’s about building long-term partnerships with suppliers that understand your needs and can grow with your business.

FAQ About Die Casting in Slovakia

1. What industries do Slovak die casting suppliers primarily serve?

Slovak die casting firms focus most heavily on the Automobilindustrie (Berücksichtigung 70% of total die casting output), followed by electronics, industrielle Fertigung, und Luft- und Raumfahrt. Many suppliers also serve niche sectors like medical devices (producing precision zinc components) and renewable energy (Z.B., aluminum parts for solar panels).

2. What lead times can I expect for die casting projects in Slovakia?

Lead times vary based on part complexity, Material, and order volume. For standard aluminum or zinc parts with existing dies, Die Vorlaufzeiten betragen typischerweise 2–4 Wochen. For custom parts requiring new die design and production, Die Vorlaufzeiten reichen von 6 bis 12 Wochen (including die testing and validation). Rush orders may be possible for an additional fee.

3. Do Slovak suppliers offer design assistance for die casting parts?

Ja, most reputable suppliers provide Design für Herstellbarkeit (DFM) Dienstleistungen. Their engineers can review your part designs to optimize them for die casting—e.g., adjusting wall thicknesses, adding draft angles, or modifying features to reduce defects and lower costs. This service is often free for new clients.

4. Are Slovak die casting products compliant with European regulations?

Absolut. All major Slovak suppliers adhere to EU standards, including REACH (restrictions on hazardous substances) and RoHS (limits on lead, Quecksilber, and other toxins). Für Automobilteile, suppliers meet IATF 16949, and for aerospace, they comply with AS9100. Most can provide certification documents upon request.

5. Can Slovak suppliers handle large-volume production runs?

Ja. Many Slovak die casting firms have the capacity for high-volume production. Zum Beispiel, some automotive suppliers can produce over 1 million aluminum parts per month using automated production lines. They also offer flexible scaling—so whether you need 1,000 Teile oder 100,000 Teile, they can adjust to your needs.