In the world of modern manufacturing, finding a reliable and efficient way to produce complex metal parts is crucial for businesses across industries. Hier die casting service shines as a cornerstone of precision engineering. Egal, Luft- und Raumfahrt, Elektronik, oder Konsumgüter, understanding the ins and outs of die casting can transform your production process, Kosten senken, and elevate product quality. This comprehensive guide will walk you through everything you need to know about die casting services, from their core principles to selecting the right provider for your project.

What Is Die Casting Service?

Die casting service refers to a manufacturing process where molten metal is forced into a mold cavity under high pressure, allowing it to take the shape of the mold before cooling and solidifying. Die Form, known as a die, is typically made from high-grade steel and designed to produce consistent, intricate parts with tight tolerances. Unlike other metal forming methods such as forging or machining, die casting excels at creating complex geometries in a single production step, making it a preferred choice for mass production.

Im Kern, a die casting service involves several key stages: Entwurfsberatung, die creation, metal melting, Injektion, Kühlung, Auswurf, und fertig. Each stage requires specialized expertise and equipment to ensure the final product meets exact specifications. Modern die casting services leverage advanced technologies like computer-aided design (CAD) and simulation software to optimize mold designs, reduce defects, and shorten production cycles.

Key Advantages of Using Professional Die Casting Services

Choosing a professional die casting service offers numerous benefits that make it a superior option for metal part production compared to alternative methods. Here are the most significant advantages:

- High Precision and Consistency: Professional die casters can achieve tight tolerances (often as low as ±0.005 inches) and maintain consistent part quality across large production runs. This is critical for industries like automotive and aerospace, where part performance directly impacts safety.

- Cost-Effectiveness for Mass Production: Once the initial die is created, the per-unit cost of die casting decreases significantly for large volumes. A study by the American Die Casting Association found that die casting can reduce production costs by 20-50% compared to machining for runs exceeding 10,000 Einheiten.

- Complex Geometries and Intricate Details: Die casting allows for the creation of parts with complex shapes, dünne Wände, and detailed features that would be difficult or impossible to achieve with other methods. This includes undercuts, Themen, and logos that can be integrated directly into the mold.

- Überlegene Oberfläche: Die cast parts typically have a smooth surface finish (RA -Werte so niedrig wie 1.6 μm), reducing the need for additional post-processing steps like polishing or grinding. This saves time and lowers overall production costs.

- Material Vielseitigkeit: Professional die casting services support a wide range of metals, einschließlich Aluminium, Zink, Magnesium, und Kupferlegierungen, each offering unique properties to suit specific applications.

- Fast Production Cycles: Modern die casting machines can produce hundreds or even thousands of parts per hour, enabling quick turnaround times for urgent projects. Lead times for die casting services typically range from 2-6 Wochen, depending on part complexity and order size.

Types of Die Casting Processes Offered by Leading Services

Reputable die casting services offer various processes tailored to different materials, part requirements, und Produktionsvolumen. Understanding the differences between these processes can help you choose the right one for your project:

Heiße Kammerstirbsguss

Heiße Kammerstirbsguss, also known as gooseneck die casting, is ideal for low-melting-point metals such as zinc, führen, and tin alloys. In this process, the injection mechanism is submerged in a molten metal bath, allowing for fast cycle times (Typischerweise 15-30 cycles per minute). This makes it highly efficient for high-volume production of small to medium-sized parts like zipper pulls, Spielzeugkomponenten, and electrical connectors.

Vorteile:

- Fast production cycles

- Lower energy consumption (no need to reheat metal for each cycle)

- Suitable for thin-walled parts

Einschränkungen:

- Limited to low-melting-point metals

- Not ideal for large parts due to machine size constraints

Kaltkammer -Sterblichkeitsguss

Cold chamber die casting is used for high-melting-point metals such as aluminum, Magnesium, und Kupferlegierungen. Unlike hot chamber machines, the molten metal is poured into a separate cold chamber before being injected into the die. This process is slower than hot chamber die casting (5-15 cycles per minute) but offers greater flexibility for larger parts and high-strength alloys.

Vorteile:

- Compatible with high-melting-point metals

- Can produce larger and thicker-walled parts

- Better suited for high-strength alloys required in structural applications

Einschränkungen:

- Longer cycle times than hot chamber processes

- Higher energy consumption due to metal reheating

Vakuumkaste

Vacuum die casting is a specialized process where the mold cavity is evacuated before metal injection, reducing the risk of porosity and air bubbles in the final part. This results in higher-quality castings with improved mechanical properties, making it ideal for critical applications in aerospace and medical devices.

Vorteile:

- Reduced porosity (bis zu 90% fewer defects compared to conventional methods)

- Improved structural integrity and strength

- Better surface finish and dimensional accuracy

Einschränkungen:

- Higher equipment and operational costs

- Slightly longer cycle times due to vacuum setup

Material Selection in Die Casting Services

The choice of material is a critical decision in die casting, as it directly impacts part performance, kosten, and production feasibility. Leading die casting services offer a range of metal alloys, each with unique characteristics:

| Material Alloy | Schlüsseleigenschaften | Typische Anwendungen | Dichte (g/cm³) | Zugfestigkeit (MPA) | Cost Relative to Steel |

| Aluminiumlegierung (Z.B., A380) | Leicht, korrosionsbeständig, Gute thermische Leitfähigkeit | Kfz -Teile, Kühlkörper, Gehäuse | 2.7 | 240-310 | 1.2X |

| Zinklegierung (Z.B., Lasten 3) | Hohe Duktilität, Hervorragende Oberflächenfinish, niedriger Schmelzpunkt | Unterhaltungselektronik, Hardware, Spielzeug | 6.6 | 280-320 | 1.5X |

| Magnesiumlegierung (Z.B., AZ91d) | Leicht strukturelles Metall, Hochfestes Verhältnis | Luft- und Raumfahrtkomponenten, power tools | 1.8 | 230-280 | 2.5X |

| Kupferlegierung (Z.B., Messing) | Hohe elektrische Leitfähigkeit, Korrosionsbeständigkeit | Elektrische Anschlüsse, Klempnerteile | 8.5 | 300-400 | 3.0X |

Bei der Auswahl eines Materials, consider factors such as mechanical requirements (Stärke, Härte), Umweltbedingungen (Temperatur, Korrosion), weight constraints, und Budget. A professional die casting service will provide material consultation to help you choose the optimal alloy for your application.

Industries Benefiting from Die Casting Services

Die casting services cater to a diverse range of industries, thanks to their versatility, Präzision, und Kosteneffizienz. Here’s how different sectors leverage die casting:

Automobilindustrie

The automotive industry is the largest consumer of die casting services, accounting for approximately 50% of global die casting production. Die cast parts are used in engine components, Übertragungssysteme, chassis parts, and interior accessories. Aluminum die castings, insbesondere, help reduce vehicle weight, improving fuel efficiency and reducing emissions. Zum Beispiel, a typical passenger car contains 15-25 kg of die cast aluminum parts.

Luft- und Raumfahrt und Verteidigung

In aerospace and defense, die casting services produce lightweight, high-strength components that meet strict safety and performance standards. Magnesium and aluminum die castings are used in aircraft frames, Motorteile, and military equipment, where weight reduction and durability are critical. Die casting ensures the consistency and precision required for these mission-critical applications.

Electronics and Telecommunications

The electronics industry relies on die casting services for producing housings, Kühlkörper, and connectors for devices such as smartphones, Laptops, and communication equipment. Zinc die castings are popular for their excellent surface finish, allowing for decorative and functional parts that meet aesthetic requirements. Die casting also enables the production of complex heat sink designs that optimize thermal management in electronic devices.

Consumer Goods and Appliances

From kitchen appliances to power tools, die casting services produce durable, cost-effective parts for consumer goods. Aluminum die castings are commonly used in appliance frames and motor housings, while zinc die castings are found in handles, Knöpfe, and decorative components. Die casting allows manufacturers to create parts with consistent quality, even for large production runs, ensuring product reliability and customer satisfaction.

Medizinprodukte

The medical device industry benefits from die casting services for producing precision components such as surgical instruments, diagnostic equipment parts, and device housings. Die casting ensures the high level of accuracy and cleanliness required for medical applications, with many die casters offering ISO 13485 certification to meet medical industry standards.

How to Choose the Right Die Casting Service Provider

Selecting the right die casting service provider is crucial for ensuring the success of your project. Here are key factors to consider:

Technical Expertise and Experience

Look for a provider with extensive experience in your industry and with your specific material and process requirements. Ask about their engineering team’s qualifications, past projects, and ability to assist with design optimization. A reputable die casting service will have a track record of producing high-quality parts for similar applications.

Qualitätskontrollmaßnahmen

Quality should be a top priority. Inquire about their quality control processes, including inspection methods (Z.B., CMM, Röntgenaufnahme, visuelle Inspektion), Zertifizierung (Z.B., ISO 9001, Iatf 16949 für Automobile), und Fehlerquoten. A reliable provider will have a defect rate of less than 0.5% for standard parts and can provide statistical process control (SPC) data to demonstrate consistency.

Production Capacity and Lead Times

Ensure the provider has the capacity to meet your production volume requirements, both for initial runs and ongoing production. Ask about their machine capabilities (Größe, tonnage), maximum part dimensions, and typical lead times. A flexible provider should be able to accommodate rush orders when needed.

Design and Engineering Support

Choose a die casting service that offers design for manufacturability (DFM) support to optimize your part design for die casting. This can help reduce costs, improve quality, and shorten production times. Look for providers with in-house design engineers and access to CAD/CAM software and simulation tools.

Kosten Transparenz

A trustworthy die casting service will provide clear, detailed quotes that include all costs, such as die creation, Material, Produktion, fertig, und Versand. Be wary of providers with vague pricing or hidden fees. Compare quotes from multiple providers to ensure you’re getting a fair price, but remember that the lowest cost may not always equate to the best quality.

Advanced Technologies in Modern Die Casting Services

The die casting industry has embraced advanced technologies to improve efficiency, Qualität, and capabilities. Here are some of the cutting-edge technologies used by leading die casting services:

Computergestütztes Design (CAD) and Simulation

CAD software allows engineers to create detailed 3D models of die cast parts and molds, enabling precise design and optimization. Simulation tools, such as flow analysis software, predict how molten metal will fill the mold, helping identify potential issues like air traps or uneven filling before the die is manufactured. This reduces the need for costly die modifications and improves first-pass yield.

Robotics and Automation

Many die casting services use robotics for tasks such as part extraction, Trimmen, und Inspektion. Automation increases production efficiency, reduces labor costs, and improves consistency by minimizing human error. Robotic systems can operate 24/7, enabling higher production volumes and faster turnaround times.

Real-Time Monitoring and IoT Integration

Advanced die casting machines are equipped with sensors that monitor key parameters such as temperature, Druck, and cycle time in real-time. This data is analyzed using IoT (Internet of Things) platforms to detect anomalies, predict maintenance needs, and optimize process parameters. Real-time monitoring can reduce defect rates by up to 30% und verlängern die Lebensdauer der Ausrüstung durch 15-20%.

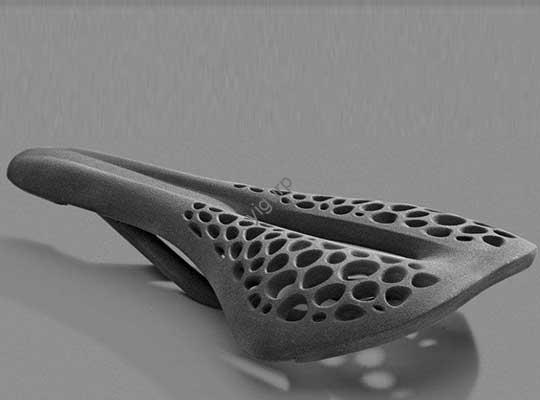

Additive Manufacturing for Prototyping

Some die casting services use 3D printing (Additive Fertigung) to create prototype dies or sacrificial patterns for small-batch production. This allows for faster prototyping (reducing lead times from weeks to days) and enables testing of part designs before investing in expensive production dies. Additive manufacturing is particularly useful for complex geometries that would be difficult to produce with traditional prototyping methods.

Environmental Considerations in Die Casting Services

As sustainability becomes increasingly important, leading die casting services are implementing practices to reduce their environmental impact:

- Recycling Programs: Die casting generates minimal waste, as excess material and scrap can be recycled and reused. Most die casters have recycling programs that recover 95% or more of metal scrap, reducing the need for virgin materials and lowering energy consumption.

- Energieeffizienz: Modern die casting machines are designed to be more energy-efficient, with variable speed pumps and heat recovery systems that reduce energy usage by 15-20% Im Vergleich zu älteren Modellen.

- Emission Reduction: Advanced filtration systems and pollution control technologies minimize emissions of volatile organic compounds (VOCs) and particulate matter. Many die casting services are also switching to water-based lubricants to reduce hazardous waste.

- Nachhaltige Materialien: Some providers offer recycled or low-carbon aluminum alloys, which have a significantly lower environmental footprint than virgin materials. Zum Beispiel, using recycled aluminum reduces energy consumption by 95% compared to producing aluminum from bauxite ore.

Yigu Technology’s Perspective on Die Casting Services

Bei Yigu Technology, Wir glauben die casting service ist das Rückgrat von effizientem, high-quality metal manufacturing. Our expertise lies in blending precision engineering with advanced technologies to deliver tailored solutions across industries. We prioritize material innovation and sustainable practices, ensuring each project balances performance, kosten, und Umweltverantwortung. By focusing on collaborative design and rigorous quality control, we empower clients to turn complex concepts into reliable, mass-produced parts that drive industry progress.

Häufig gestellte Fragen (FAQ)

- What is the typical lead time for a die casting service?

Lead times vary based on part complexity, die creation, and order size. For new projects requiring custom dies, lead times are usually 4-8 Wochen. For repeat orders using existing dies, production can often be completed in 2-4 Wochen.

- How much does a custom die cost for die casting?

Die costs depend on size, Komplexität, und Material. Klein, simple dies may cost \(5,000-\)15,000, während groß, complex dies for automotive or aerospace parts can range from \(50,000-\)200,000 oder mehr. Jedoch, dies can produce hundreds of thousands of parts, making the per-unit cost very low for large production runs.

- Can die casting services handle low-volume production?

Ja, but die casting is most cost-effective for medium to high volumes (10,000+ Einheiten). Für die Produktion mit niedrigem Volumen (Weniger als 5,000 Einheiten), some providers offer prototype die casting or use alternative methods like sand casting. Discuss your volume requirements with the provider to find the most economical solution.