Metalldruckguss-Service

Yigu Technology ist auf die Lieferung spezialisiert hoch – Hochwertige Metallstanze – Gussteile mit außergewöhnlicher technischer Präzision. Unser Staat – von – Die – Kunstprozesse sorgen für schnelle Produktionszyklen, So können wir zuverlässig weiterhelfen – pünktliche Lieferung. Von der ersten Prototypenphase bis zur Vollständigkeit – Massenproduktion im Maßstab, Wir nutzen unsere fortschrittlichen Technologien und unser Fachwissen, um Ihren Erfolg in Metall zu verwandeln – Schneller, schlauer, und besser. Wir sind bestrebt, diese überlegenen Komponenten zu wettbewerbsfähigen Preisen anzubieten, Wir stellen sicher, dass unsere Kunden den besten Gegenwert für ihre Investition erhalten.

Unsere Kompetenz im Metalldruckguss

Yigu Technology ist ein führender Anbieter von Druckgusslösungen, einschließlich HPDC, LPDC, Quetschen und so weiter, ausgestattet mit über 30 fortschrittliche Maschinen, um beispiellose Qualität und Effizienz zu gewährleisten. Unser Staat – von – Die – Art Facility verfügt über Zertifizierungen wie ISO 9001,, die unsere strikte Einhaltung der höchsten Industriestandards belegen. Wir zeichnen uns durch hohe Qualität aus – Präzision, hoch – Massenproduktion in verschiedenen Branchen, einschließlich Automobil- und Medizinanwendungen, mit strengen Qualitätskontrollmaßnahmen.

Unser Industrie – führende Druckgusstechnologie ist auf Präzisionskomponenten aus Aluminium spezialisiert, Magnesium, und Zinklegierungen. Hier sind die wichtigsten Highlights unseres Wettbewerbsvorteils:

- Ultra – Enge Toleranzen: Wir erreichen Toleranzen von bis zu ±0,02 mm, Erfüllung der anspruchsvollsten Anforderungen im Automobilbereich, Elektronik, und medizinische Anwendungen.

- Hoch – Massenproduktion: Unsere vollautomatischen Produktionslinien sorgen für schnelle Durchlaufzeiten, So können wir enge Fristen einhalten, ohne Kompromisse bei der Qualität einzugehen.

- Ende – Zu – Kontrolle beenden: Wir bieten integrierte Dienstleistungen an, die den gesamten Produktionsprozess abdecken, vom Formenentwurf bis zur Post – Verarbeitung, Dadurch haben wir die vollständige Kontrolle über die Qualität und Konsistenz unserer Produkte.

- Materialkompetenz: Wir haben drin – fundierte Kenntnisse über kundenspezifische Legierungen, So können wir Leichtgewichte schaffen, Korrosion – beständig, und hoch – Stärkekomponenten, die auf Ihre spezifischen Bedürfnisse zugeschnitten sind.

Arbeiten Sie mit Yigu Technology zusammen, um zuverlässig zu sein, nachhaltig, und Kosten – effektive Druckgussdienstleistungen, die die Erwartungen stets übertreffen.

Kalte Kammer

Beim Kaltkammer-Druckguss wird geschmolzenes Metall unter hohem Druck präzise in eine Form eingespritzt, hochfeste Metallteile.

Heiße Kammer

Heißkammer-Druckguss schmilzt und spritzt Metall schnell ein, Ideal für niedrig schmelzende Legierungen wie Zink, Sicherstellung schnell, effiziente Produktion.

Vakuumunterstützt

Beim vakuumunterstützten Druckguss wird Luft aus dem Formhohlraum entfernt, Reduzierung der Porosität und Verbesserung des Metallflusses für eine höhere Qualität, dichte Gussteile.

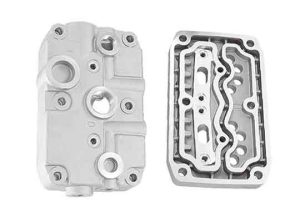

Anzeige von Metalldruckgussteilen

Die unten angezeigten Produkte wurden vom Kunden genehmigt, und wir halten uns strikt an die Vertraulichkeitsvereinbarung.

Unsere Optionen für Druckgussmaterialien

Beim Druckguss wird eine große Auswahl an Metallen verwendet, Damit eignet es sich ideal für viele Anwendungen in nahezu jeder Branche.

Unser Niveau der Druckgusstechnologie

Im Bereich Druckguss, Die Auswertung von Leistungskennzahlen ist entscheidend für die Effizienzmessung, Qualität, und Wirtschaftlichkeit. Zu den wichtigsten Leistungsindikatoren gehören: Zykluszeit, Fehlerrate, Maßhaltigkeit, Oberflächenbeschaffenheit, Und Lebensdauer der Werkzeuge.

Unsere Druckgusslösungen sind mit fortschrittlichen Funktionen ausgestattet, um den anspruchsvollsten Anforderungen gerecht zu werden. Der maximale Spannkraft unserer Maschinen erreicht beeindruckende 2500T, Gewährleistung robuster und zuverlässiger Formprozesse. Wir können ein erreichen Mindestwandstärke von 0,5mm, Dies ist ideal für die Herstellung leichter und dennoch robuster Komponenten. Zusätzlich, unser Standard Oberflächenbeschaffenheit beträgt Ra1,6μm, mit der Option einer Nachbearbeitung zur Verbesserung auf Ra0,8μm, Bereitstellung eines erstklassigen Finishs, das den höchsten Qualitätsstandards entspricht.

Schließen Sie Ihren Druckguss- und Fertigungsprozess ab 5 Schritte

Warum sollten Sie sich für Yigu Metalldruckguss entscheiden??

Bei Yigu Technology, Wir sind auf die Herstellung von spezialisiert hochpräzise und langlebig Druckgussteile. Unsere hochmoderne Technologie und strengen Qualitätskontrollprozesse stellen sicher, dass unsere Produkte in anspruchsvollen Branchen wie z. B. einwandfreie Leistung erbringen Automobil, Luft- und Raumfahrt, und industrielle Fertigung.

Jede Komponente, die wir produzieren, hält sich daran globale Standards, Gewährleistung von Zuverlässigkeit und Wirtschaftlichkeit. Durch die Partnerschaft mit Yigu Technology, Sie erhalten Zugang zu maßgeschneiderten Lösungen, die auf Ihre spezifischen Bedürfnisse zugeschnitten sind, Alles gestützt auf unser Engagement für Spitzenleistungen.

Vorteile von Druckguss

Hochpräzise Fertigung: Dafür sorgt unsere fortschrittliche Druckgusstechnologie enge Toleranzen (±0,05 mm), Damit eignet es sich ideal für komplexe Geometrien und reduziert gleichzeitig den Bedarf an Nachbearbeitung deutlich.

Leichtbau-Materialkompetenz: Wir verfügen über bewährte Kompetenzen im Druckgussbereich Aluminium Und Magnesiumlegierungen, Erreichen der perfekten Balance zwischen Kraft und Gewichtsreduzierung. Dies ist insbesondere für Anwendungen in der Automobil- und Elektronikindustrie von Vorteil.

Produktionseffizienz bei hohen Stückzahlen: Unsere automatisierten Produktionslinien ermöglichen schnelle und große Lieferungen zu reduzierten Kosten, Dies macht uns zur idealen Wahl für die Erfüllung der Anforderungen der Massenproduktion.

Druckgussanwendungen

Automobil: Wir sind auf die Herstellung kritischer Komponenten spezialisiert, z Motorgehäuse, Getriebeteile, Und Batteriefächer für Elektrofahrzeuge, Gewährleistung von Haltbarkeit und Präzision für die Automobilindustrie.

Elektronik: Unsere Expertise erstreckt sich auf den Elektronikbereich, wo wir produzieren 5G-Kühlkörper, Smartphone-Rahmen, Und Anschlüsse, Bereitstellung leistungsstarker Lösungen für moderne Technologie.

Medizinisch: Im medizinischen Bereich, wir fertigen Komponenten chirurgischer Instrumente Und Teile von bildgebenden Geräten, Aufrechterhaltung höchster Qualitäts- und Zuverlässigkeitsstandards für kritische Anwendungen.