Our CNC Polishing Services

Elevate your parts’ aesthetics and performance with our CNC Polishing services—the gold standard for precision polishing and consistent surface finishes across industries. Leveraging advanced automated polishing technology, we transform metals (stainless steel, titanium), plastics, composites, and glass into flawless components with Ra values as low as 0.02μm. Whether you need mirror-like medical tools, corrosion-resistant aerospace parts, or sleek consumer goods, our custom solutions blend efficiency, versatility, and uncompromising quality—reducing manual labor and ensuring every part shines.

What Is CNC Polishing?

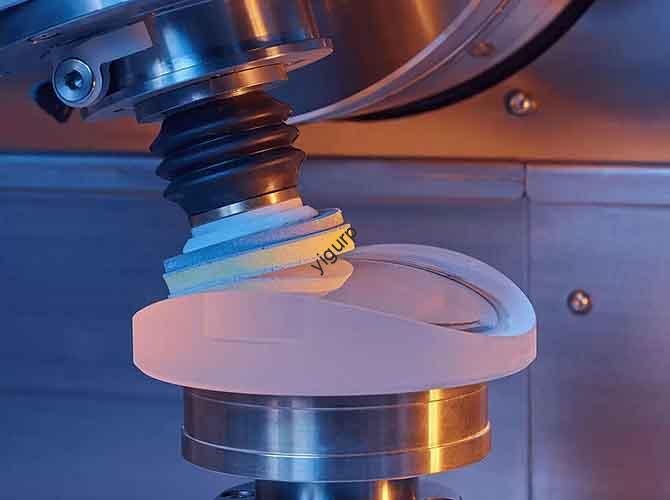

CNC Polishing is an advanced surface-finishing technology that uses computer-controlled machines to smooth, refine, and enhance the surface of materials—replacing manual polishing with automated precision. Unlike manual polishing (which relies on human skill and is prone to inconsistency), it uses pre-programmed tool paths and specialized abrasives to achieve uniform, repeatable results.

The process overview is straightforward: A CNC (Computer Numerical Control) system interprets design files to guide polishing tools (e.g., buffing wheels, abrasive pads) across the material’s surface. The machine adjusts pressure, speed, and abrasive grit based on the material and desired finish—removing micro-imperfections (scratches, tool marks) without altering the part’s dimensions.

To explain “how it works” simply: Imagine a robot armed with a series of fine sandpapers and buffing pads, following a digital map to polish every inch of a part. For a stainless steel medical tool, the CNC machine first uses a coarse abrasive to remove machining marks, then progresses to finer grits to create a mirror finish—all without human error. This blend of automation and precision is what makes CNC Polishing superior to manual methods, especially for complex or high-volume parts.

Our CNC Polishing Capabilities

We offer comprehensive polishing capabilities tailored to diverse materials and finish requirements, with a focus on precision levels, surface finish quality, and flexibility. Below is a detailed breakdown of our key capacities:

| Capability | Specification |

| Precision Levels | – Surface roughness (Ra): 0.02μm–1.6μm (mirror finish to matte finish)- Dimensional tolerance retention: ±0.001mm (no part distortion) |

| Tolerance Achievements | – Maintains original part tolerances (meets ISO 2768-1 fine grade)- Uniformity: ±0.05μm Ra variation across the part surface |

| Maximum Part Size | – Small parts: 0.5mm × 0.5mm × 0.5mm (micro-components like medical needles)- Large parts: 3000mm × 1500mm × 800mm (aerospace panels, automotive body parts)- Weight: Up to 500kg |

| Material Compatibility | – Metals: Stainless steel, aluminum, titanium, brass, copper, exotic metals (inconel, tantalum)- Non-Metals: Plastics (ABS, polycarbonate), composites, glass, ceramics- Special Materials: High-performance polymers (PEEK), optical glass |

| Custom Polishing | – Finish types: Mirror (Ra ≤ 0.05μm), satin (Ra 0.1–0.2μm), matte (Ra 0.8–1.6μm), brushed (linear grain)- Complex geometries: Internal cavities, curved surfaces, undercuts (via 5-axis polishing heads) |

| Surface Finish Quality | – Meets industry standards: ASTM B607 (metal polishing), ISO 8785 (surface roughness)- Specialized finishes: Electropolished (for corrosion resistance), chemically polished (for plastics) |

| Quality Assurance | – In-line inspection: Laser profilometers (real-time Ra measurement)- Post-polishing: Optical comparators, CMMs (verify dimensions and finish)- Compliance: ISO 9001, AS9100 (aerospace), ISO 13485 (medical) |

Whether you need 100 titanium orthopedic implants with a 0.03μm Ra finish or 10,000 aluminum smartphone casings with a satin finish, our capabilities scale to match your project’s needs.

The CNC Polishing Process (Step-by-Step)

Our step-by-step process is optimized to deliver consistent, high-quality finishes while preserving the part’s original dimensions:

- Design and CAD Modeling: We start by reviewing your part’s CAD model and finish requirements (e.g., Ra value, finish type). Our engineers identify critical areas (e.g., bearing surfaces that need ultra-smooth finishes) and select the best polishing technique (mechanical, chemical, or electrochemical) for the material.

- CAM Programming: The CAD model is imported into CAM software (Mastercam, SolidWorks CAM) to generate tool paths—mapping the polishing tool’s movement across the part. We program parameters like tool speed (500–3000 RPM), pressure (1–10 N), and abrasive grit sequence (coarse → medium → fine) to achieve the desired finish.

- Setup and Calibration: The part is secured in custom fixture design (e.g., vacuum chucks for thin parts, soft jaws for delicate plastics) to prevent movement. We calibrate the polishing tool’s pressure and alignment using laser sensors—ensuring it follows the tool path without altering the part’s dimensions. Abrasives and coolant systems (for heat-sensitive materials) are loaded.

- Polishing Execution: The CNC machine runs the program, progressing through the abrasive sequence. For example:

- Mechanical Polishing: Uses rotating buffing wheels with abrasive compounds (alumina for metals, diamond for ceramics) to remove imperfections.

- Electrochemical Polishing: Applies an electric current and chemical solution to dissolve surface imperfections (ideal for stainless steel medical parts).

- Vibratory Polishing: Tumbles small parts with abrasive media (ceramic beads) for uniform finishing (great for high-volume small components like brass connectors).

Post-Polishing Inspection: Parts undergo rigorous quality control—we measure surface roughness with a profilometer, check for uniformity with an optical comparator, and verify dimensions with a CMM. Parts that meet the Ra requirement move to final packaging; those that don’t are reworked with adjusted parameters.

Materials We Work With

CNC Polishing works with almost every material, but the technique and abrasives vary based on the material’s hardness and properties. Below is a breakdown of our supported materials, recommended polishing techniques, and ideal finishes:

| Material Category | Examples | Key Properties | Recommended Polishing Technique | Ideal Finish (Ra Value) | Common Applications |

| Metals | Stainless Steel | Corrosion-resistant, hard | Electrochemical polishing, mechanical | 0.02μm–0.1μm (mirror) | Medical tools, food processing equipment |

| | Aluminum | Lightweight, soft, prone to oxidation | Mechanical polishing (with oxide inhibitors) | 0.05μm–0.2μm (satin) | Automotive trim, electronics casings |

| | Titanium | High strength, biocompatible, hard | Mechanical polishing (diamond abrasives) | 0.03μm–0.1μm (mirror) | Orthopedic implants, aerospace components |

| | Brass | Malleable, conductive, tarnishes easily | Mechanical polishing (buffing wheels) | 0.05μm–0.1μm (mirror) | Electrical connectors, decorative parts |

| | Copper | Soft, conductive, prone to oxidation | Chemical polishing (acid-based) | 0.05μm–0.2μm (satin) | Heat exchangers, musical instruments |

| Non-Metals | Plastics (ABS/Polycarbonate) | Lightweight, soft, prone to melting | Mechanical polishing (fine abrasive pads) | 0.1μm–0.8μm (matte) | Consumer goods casings, prototypes |

| | Composites | Layered structure, abrasive-sensitive | Mechanical polishing (low-pressure, fine grit) | 0.2μm–1.6μm (matte) | Aerospace panels, racing car parts |

| | Glass | Hard, brittle, scratch-prone | Mechanical polishing (diamond abrasives) | 0.02μm–0.05μm (optical) | Optical lenses, display screens |

| | Ceramics | Hard, heat-resistant, brittle | Mechanical polishing (diamond pads) | 0.02μm–0.1μm (mirror) | Medical implants, industrial valves |

| Special Materials | Exotic Metals (Inconel) | Heat-resistant, hard | Mechanical polishing (ceramic abrasives) | 0.1μm–0.3μm (satin) | Aerospace engine parts |

| | High-Performance Polymers (PEEK) | Heat-resistant, chemical-resistant | Mechanical polishing (non-abrasive pads) | 0.2μm–0.8μm (matte) | Medical device casings, industrial seals |

Surface Treatment & Finishing Options

CNC Polishing is often paired with complementary surface treatment techniques to enhance durability, aesthetics, or functionality. Below are our most popular finishing options, along with their benefits and ideal uses:

| Finishing Option | Process Description | Key Benefits | Material Compatibility | Cost (per sq. meter, avg.) | Best For |

| Mechanical Polishing | Uses rotating abrasive tools (buffing wheels, pads) to remove imperfections | Fast, cost-effective, customizable finish | All metals, plastics, composites | 50–150 | High-volume parts (automotive trim) |

| Electrochemical Polishing | Uses electric current + chemical solution to dissolve surface flaws | Corrosion-resistant, uniform finish, no tool marks | Stainless steel, titanium, brass | 80–200 | Medical tools, food-grade parts |

| Chemical Polishing | Uses acid/base solutions to etch away surface imperfections | No contact (ideal for delicate parts), fast | Copper, brass, plastics | 40–120 | Small, complex plastic parts |

| Vibratory Polishing | Tumbles parts with abrasive media (ceramic beads, plastic chips) | Uniform finish for small parts, low labor | Small metals (brass pins), plastics | 20–80 | Electronics connectors, jewelry |

| Buffing | Uses soft cloth wheels + polishing compounds (wax, rouge) to create shine | Mirror finish, enhanced aesthetics | Stainless steel, brass, aluminum | 60–180 | Decorative parts, consumer goods |

| Brushed Finishing | Uses linear abrasive pads to create parallel grain patterns | Hides fingerprints, matte aesthetic | Aluminum, stainless steel | 45–130 | Appliance panels, smartphone casings |

| Coating Removal | Uses fine abrasives to strip old coatings (paint, plating) before re-polishing | Prepares parts for re-finishing, cost-saving | All metals, plastics | 30–100 | Refurbished parts (industrial machinery) |

For example, we use electrochemical polishing for stainless steel medical tools (to ensure corrosion resistance) and brushed finishing for aluminum smartphone casings (to hide fingerprints while maintaining a sleek look).

Tolerances & Quality Assurance

Tolerances for CNC Polishing focus on two key metrics: surface roughness (Ra value) and dimensional stability (ensuring polishing doesn’t alter the part’s original dimensions). Our quality control processes are designed to meet strict industry standards:

| Material | Target Ra Range | Ra Uniformity Tolerance | Dimensional Tolerance Retention | Accuracy Standard Used | Measurement Technique |

| Stainless Steel | 0.02μm–0.1μm | ±0.05μm | ±0.001mm | ASTM B607, ISO 8785 | Laser Profilometer + CMM |

| Aluminum | 0.05μm–0.2μm | ±0.08μm | ±0.002mm | ISO 8785, AMS 2750 | Profilometer + Optical Comparator |

| Titanium | 0.03μm–0.1μm | ±0.06μm | ±0.001mm | ISO 8785, AMS 4928 | Laser Profilometer + CMM |

| Glass | 0.02μm–0.05μm | ±0.03μm | ±0.0005mm | ISO 10110, ASTM C1036 | Optical Profilometer + Interferometer |

| ABS Plastic | 0.1μm–0.8μm | ±0.1μm | ±0.005mm | ISO 8785, ASTM D638 | Profilometer + Micrometer |

Our quality control processes include:

- Pre-polishing: Inspecting parts for initial surface condition (e.g., machining marks, scratches) and verifying dimensions.

- In-process: Real-time Ra measurement with laser profilometers (adjusting tool pressure/speed if Ra deviates from target).

- Post-polishing: 100% inspection for critical parts (medical, aerospace); statistical sampling (5–10%) for high-volume parts. We also conduct adhesion tests (for coated parts) and corrosion tests (for metals).

Documentation: Providing a finish report with every order, including Ra values, measurement locations, and compliance certificates.

Key Advantages of CNC Polishing

Compared to manual polishing or other finishing methods, CNC Polishing offers unmatched benefits for consistency, efficiency, and quality:

- High Precision: Achieves surface roughness as low as 0.02μm—critical for parts like optical lenses (where even tiny imperfections affect performance) or medical implants (where smooth surfaces reduce tissue irritation).

- Consistency and Repeatability: CNC programming ensures every part has the same finish—no variation from part to part (unlike manual polishing, where results depend on the operator’s skill).

- Complex Geometries: 5-axis CNC polishing heads reach internal cavities, curved surfaces, and undercuts—finishing areas manual methods can’t access (e.g., the inside of a titanium knee implant).

- Reduced Setup Time: CAM programming and automated tool changes cut setup time by 60–80% compared to manual polishing—ideal for high-volume runs (e.g., 10,000 aluminum casings).

- Increased Efficiency: CNC machines run 24/7 with minimal supervision—producing 3–5x more parts per hour than manual polishers.

- Versatility: Works with almost every material (metals, plastics, glass, composites) and can create any finish (mirror, satin, brushed).

- Cost-Effectiveness: While upfront costs are higher than manual polishing, reduced labor costs (no need for skilled operators) and lower rework rates (fewer inconsistent parts) save money long-term—especially for high-volume orders.

- Improved Surface Finish: Removes micro-imperfections (machining marks, scratches) that manual polishing misses—enhancing aesthetics and functionality (e.g., smooth surfaces reduce friction in moving parts).

- Enhanced Aesthetics: Creates uniform, professional finishes that boost product value—critical for consumer goods (e.g., smartphones, jewelry) and decorative parts.

Reduced Manual Labor: Eliminates repetitive, labor-intensive manual polishing—reducing worker fatigue and improving workplace safety.

Industry Applications

CNC Polishing is used across industries where surface finish impacts performance, aesthetics, or compliance. Here are its most common applications:

| Industry | Common Uses | Key Benefit of CNC Polishing |

| Aerospace | Titanium engine components, aluminum fuselage panels, stainless steel fuel lines | Corrosion resistance + dimensional stability |

| Automotive | Aluminum trim, stainless steel exhaust tips, plastic interior panels | Aesthetics + consistency for high-volume production |

| Medical Devices | Stainless steel surgical tools, titanium orthopedic implants, plastic device casings | Smooth surfaces (reduces tissue irritation) + compliance |

| Industrial Manufacturing | Steel machinery parts, ceramic valves, composite conveyor belts | Reduced friction + durability |

| Electronics | Aluminum heat sinks, brass connectors, plastic smartphone casings | Aesthetics + improved heat dissipation (smooth surfaces) |

| Defense | Titanium weapon components, stainless steel vehicle armor parts | Corrosion resistance + durability in harsh environments |

Advanced Manufacturing Techniques in CNC Polishing

To deliver exceptional finishes across diverse materials and geometries, we leverage specialized polishing techniques and optimized processes:

9.1 Core Polishing Techniques

- Mechanical Polishing:

The most versatile technique—uses rotating tools (buffing wheels, abrasive pads) with graded grits (80–10,000 grit) to remove surface imperfections. We tailor tools to material:

- Buffing Wheels: Cotton/polyester wheels for metals (stainless steel, brass) to create mirror finishes; foam wheels for plastics to avoid melting.

- Abrasive Pads: Diamond-impregnated pads for hard materials (ceramics, glass); alumina pads for metals; silica pads for composites.

- Application: Ideal for large parts (aerospace panels) and high-volume runs (automotive trim).

- Electrochemical Polishing (ECP):

Uses an electrolytic cell (part as anode, conductive tank as cathode) and a specialized electrolyte (e.g., phosphoric acid for stainless steel). When current is applied, surface metal dissolves uniformly—removing tool marks and creating a passive oxide layer.

- Benefit: No contact (avoids part distortion) and enhances corrosion resistance.

- Application: Medical tools (stainless steel), food-grade parts (brass), and parts with internal cavities (titanium implants).

- Chemical Polishing:

Uses acid/base solutions (e.g., nitric acid for copper, sodium hydroxide for plastics) to etch away surface flaws. Unlike ECP, it requires no electricity—parts are dipped or sprayed with the solution, then rinsed.

- Benefit: Fast, low-cost for small, complex parts (e.g., plastic electronics connectors).

- Application: Copper heat exchangers, ABS plastic casings, and brass decorative parts.

- Vibratory Polishing:

Places small parts (e.g., brass pins, medical needles) in a vibrating tub filled with abrasive media (ceramic beads, plastic chips) and a polishing compound. Vibration causes media to rub against parts, creating a uniform finish.

- Benefit: Low labor (unattended operation) and consistent results for high-volume micro-parts.

- Application: Electronics connectors (brass), jewelry findings (gold-plated brass), and medical micro-components.

- 5-Axis CNC Polishing:

Uses a 5-axis machine (3 linear + 2 rotary axes) with a flexible polishing head (e.g., foam or felt) to reach complex geometries—internal cavities, undercuts, and curved surfaces (e.g., titanium knee implants).

- Benefit: Finishes areas manual or 3-axis polishing can’t access.

- Application: Aerospace turbine blades (inconel), orthopedic implants (titanium), and optical molds (steel).

9.2 Supporting Technologies

- Abrasive Selection:

Grit size and material determine finish quality:

- Coarse grit (80–240): Removes machining marks (initial step).

- Medium grit (400–800): Smooths surface (intermediate step).

- Fine grit (1000–10,000): Creates desired finish (final step).

For hard materials (ceramics, glass), we use diamond abrasives; for soft materials (aluminum, plastics), we use alumina or silica.

- Coolant Systems:

Prevents overheating (critical for plastics and soft metals):

- Water-Based Coolants: For mechanical polishing of metals—reduces friction and flushes away abrasive debris.

- Oil-Based Coolants: For plastics—avoids warping and improves finish uniformity.

- Mist Coolants: For 5-axis polishing of micro-parts—delivers a fine mist to avoid residue buildup.

- Fixture Design:

Custom fixtures ensure parts stay stable during polishing:

- Vacuum Chucks: For thin parts (aluminum sheets, glass panels) to avoid deformation.

- Soft Jaws: For delicate plastics (polycarbonate) and polished metals (brass) to prevent scratches.

Magnetic Fixtures: For ferrous metals (steel dies) to enable fast setup.

Case Studies: CNC Polishing Success Stories

Our CNC Polishing services have solved finish challenges for clients across medical, aerospace, and consumer goods industries. Below are two successful projects showcasing our expertise:

Case Study 1: Medical Device Company (Stainless Steel Surgical Scissors)

- Challenge: The client needed 50,000 stainless steel surgical scissors monthly—requiring a mirror finish (Ra ≤ 0.05μm) for corrosion resistance and easy sterilization. Their previous supplier used manual polishing, which caused 12% of scissors to have inconsistent finishes (some too rough, some with scratches) and failed FDA compliance checks. Lead time was 4 weeks, delaying product launches.

- Solution: We used electrochemical polishing (ECP)—the scissors were mounted on a custom fixture and submerged in a phosphoric acid electrolyte. We programmed the ECP system to apply 12V current for 3 minutes (optimized for stainless steel), then rinsed and passivated the scissors to enhance corrosion resistance. We added in-line laser profilometers to inspect Ra values in real time, rejecting parts with Ra > 0.05μm.

- Results:

- Finish consistency improved from 88% to 99.8%—only 100 scissors failed per month (vs. 6,000 previously).

- The scissors passed FDA compliance (corrosion resistance test: 500+ hours in salt spray).

- Lead time shortened from 4 weeks to 10 days—helping the client meet launch deadlines.

- Client Testimonial: “CNC ECP transformed our scissors’ quality. The mirror finish is perfect every time, and the FDA approval was seamless. We’ve expanded our order to include hemostats and forceps.” — Maria L., Medical Device Production Manager.

- Before and After: Manual polished scissors had visible scratches and uneven shine; ECP scissors featured a uniform mirror finish that resisted rust and simplified sterilization.

Case Study 2: Consumer Electronics Brand (Aluminum Smartphone Casings)

- Challenge: The client needed 100,000 aluminum smartphone casings monthly—requiring a brushed finish (Ra 0.15μm, linear grain) to hide fingerprints and match their brand aesthetic. Their previous supplier used manual brushing, which caused 15% of casings to have misaligned grain (some curved, some uneven) and inconsistent Ra values (0.1–0.3μm). The client needed a 2-week lead time to support their phone launch.

- Solution: We used 5-axis CNC mechanical polishing—equipping the machine with a linear abrasive pad (800 grit) and programming it to create parallel grain lines (0.5mm apart) across the casing’s curved surfaces. We used a custom vacuum fixture to secure the casings (avoiding scratches) and water-based coolant to prevent aluminum oxidation. We sampled 1% of casings hourly with a profilometer to ensure Ra stayed at 0.15μm.

- Results:

- Grain alignment accuracy improved from 85% to 99.5%—only 500 casings had misaligned grain (vs. 15,000 previously).

- Ra uniformity was maintained at ±0.02μm (all casings 0.13–0.17μm)—meeting the brand’s strict aesthetic standards.

- Lead time was met (2 weeks)—enabling the client’s on-schedule phone launch.

- Challenge Overcome: Manual brushing couldn’t follow the casing’s curved edges; 5-axis CNC ensured grain lines stayed straight and uniform across all surfaces.

Client Testimonial: “The brushed casings look identical to our design specs—no more customer complaints about fingerprint visibility. The consistency and speed have made them our sole supplier for aluminum parts.” — David K., Consumer Electronics Procurement Director.

Why Choose Our CNC Polishing Services?

With numerous CNC polishing providers, here’s what sets us apart as a trusted partner for medical, aerospace, and consumer industries:

- Expertise in CNC Polishing: Our team has 18+ years of specialized experience—we master all core techniques (mechanical, ECP, chemical, vibratory) and tailor them to material properties. Our engineers are certified in AS9100 (aerospace) and ISO 13485 (medical) and can solve complex challenges (e.g., 0.02μm finishes for optical glass, brushed grain on curved aluminum).

- Experience in Various Industries: We’ve served 650+ clients across 10 industries—from small medical startups to Fortune 500 electronics brands. This cross-industry experience means we understand sector-specific needs: FDA compliance for medical parts, scratch resistance for consumer goods, and corrosion resistance for aerospace components.

- High-Quality Equipment: We invest in state-of-the-art machines—12 CNC polishing systems (including 5 5-axis machines), 8 ECP tanks, 5 vibratory polishing tubs, and in-line laser profilometers. All equipment is calibrated weekly (using NIST-traceable standards) to maintain precision.

- Excellent Customer Service: Our team is available 24/7 to support your project—from finish selection (helping you choose the right Ra value) to post-delivery follow-up. We offer free sample polishing (up to 5 parts) so you can verify finish quality before placing large orders. For urgent projects (e.g., medical supply shortages), we assign a dedicated project manager.

- Fast Turnaround Times: Our optimized processes deliver industry-leading lead times:

- Prototypes (1–100 parts): 1–3 days

- Low-volume (100–1,000 parts): 3–7 days

- High-volume (1,000+ parts): 7–14 days

For rush orders (e.g., consumer goods launches), we can deliver 10,000+ parts in 5 days by running machines 24/7.

- Cost-Effective Solutions: We help you save money through:

- Automation: Unattended operation (vibratory, ECP) reduces labor costs by 60% vs. manual polishing.

- Abrasive Optimization: Reusing fine grit abrasives (for final steps) cuts material costs by 20%.

- Volume discounts: 10% off orders over 10,000 parts and 15% off orders over 50,000 parts—ideal for consumer electronics and medical high-volume runs.

Commitment to Quality: We’re ISO 9001, AS9100, and ISO 13485 certified—our quality control processes ensure 99.9% of parts meet your finish requirements. We also provide full traceability (each batch’s Ra reports, process logs) for compliance.