Additiv gefertigte Teile: Ein vollständiger Leitfaden für Anfänger und Profis

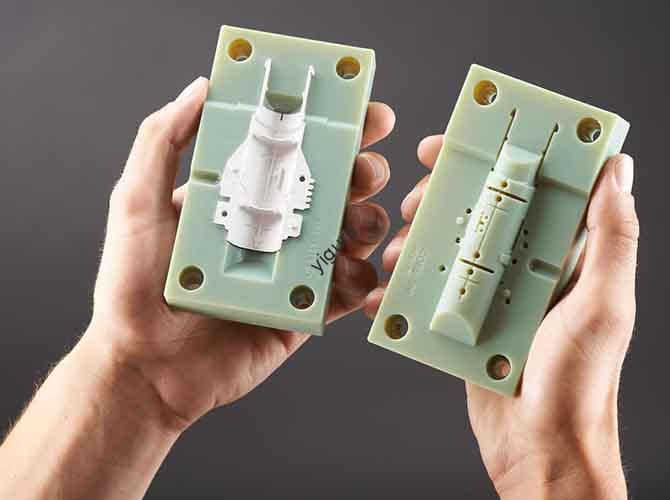

Wenn Sie sich jemals gefragt haben, was additiv gefertigte Teile sind und warum sie Branchen von der Luft- und Raumfahrt bis zum Gesundheitswesen revolutionieren, Du bist am richtigen Ort. Einfach gesagt, Additiv gefertigte Teile sind Komponenten, die durch 3D-Drucktechnologien hergestellt werden, Dabei wird Material Schicht für Schicht aufgebaut – im Gegensatz zu herkömmlichen „subtraktiven“ Methoden, bei denen Material von einem Festkörper weggeschnitten oder gebohrt wird […]