Warum ist CNC-Laserschneiddesign eine Kernkompetenz in der Industrie??

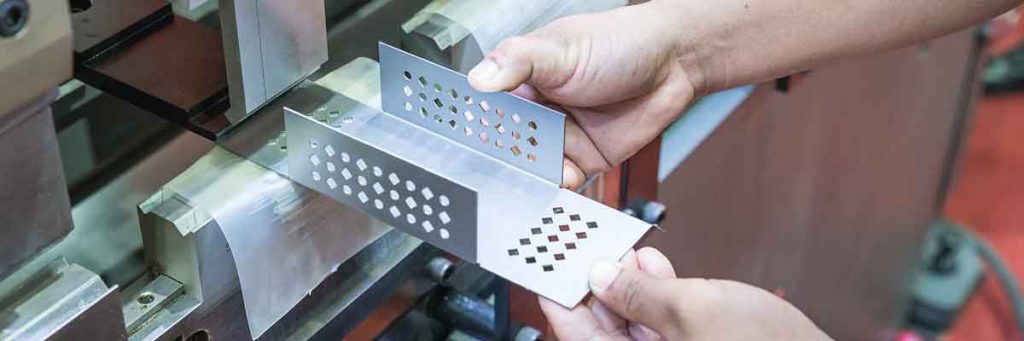

In verschiedenen Bereichen wie der industriellen Fertigung, Kunstdesign, und Autoteilebearbeitung, Das CNC-Laserschneiden hat sich mit seinen Vorteilen hoher Präzision und Effizienz zur gängigen Bearbeitungsmethode entwickelt. Jedoch, Viele Benutzer werden auf Probleme stoßen wie “unvollständiger Schnitt”, “Grate an den Kanten”, Und “Fehler beim Dateiimport” im tatsächlichen Betrieb, und der Hauptgrund […]