In 3D Druck, why do even high-quality resin prints sometimes lack strength or smoothness right after printing? Die Antwort liegt in 3D printing secondary curing—a critical post-processing step that unlocks the full potential of printed parts. Unlike primary curing (which happens during printing), secondary curing uses light or heat to further harden and refine parts, solving issues like weak interlayer bonds or rough surfaces. In diesem Artikel werden die Grundprinzipien erläutert, Schlüsselmethoden, Anwendungen in der Praxis, Sicherheitstipps, and common mistakes to avoid, helping you master this essential technique.

What Is 3D Printing Secondary Curing?

3D Printing Secondary Curing is a post-processing technique that uses external energy (light or heat) to complete the curing reaction of 3D printed parts. During primary printing (Z.B., SLA or DLP), parts are only partially cured to ensure they can be removed from the printer. Secondary curing takes these semi-cured parts and strengthens their molecular structure—think of it like “baking a cake”: the initial mix (primary cure) sets the shape, but the final bake (secondary cure) makes it firm and flavorful.

This step is especially critical for resin-based 3D printing. Ohne es, parts may be brittle, have poor heat resistance, or degrade over time. Secondary curing fixes these issues by forming more chemical bonds between polymer molecules, resulting in stronger, more durable components.

Kernprinzipien: Light Curing vs. Heat Curing

The two main secondary curing methods—light and heat—work differently, each suited for specific materials and goals. The table below compares their principles, Profis, Nachteile, und ideale Verwendungen:

| Aushärtungsmethode | Kernprinzip | Schlüsselvorteile | Einschränkungen | Ideale Materialien & Anwendungen |

|---|---|---|---|---|

| Lichthärtend | Uses ultraviolet (UV) or visible light to activate photosensitive molecules in the resin, forming new chemical bonds. | – Schnell (10–60 Minuten pro Teil)- Verbessert die Oberflächenglattheit (reduces layer lines)- No risk of thermal deformation. | – Requires material-specific light wavelengths (Z.B., 405NM für die meisten Harze)- Deep curing may be uneven for thick parts. | – SLA/DLP Resins: Zahnmodelle, Konsumgüter (Spielzeug, Telefonkoffer)- Photopolymer-based functional parts (Sensoren, kleine Klammern). |

| Heat Curing | Uses controlled heat (often 60–150°C) to trigger cross-linking reactions in polymers, hardening the material. | – Boosts heat resistance (HDT increases by 20–50°C)- Improves mechanical strength (tensile strength up by 30%)- Works for thick or large parts. | – Langsam (1–4 hours per part)- Risk of warping if temperature is too high- Requires precise temperature control. | – Hochtemperaturharze: Luft- und Raumfahrtkomponenten, Kfz -Motorteile- Thermoplastic-based prints (Z.B., ABS, PC blends) brauchen zusätzliche Starrheit. |

Key Benefits of 3D Printing Secondary Curing

Secondary curing isn’t just an “extra step”—it solves real-world problems for 3D printing users. Hier sind 3 core benefits with concrete examples:

1. Enhances Mechanical Performance

- Problem: A hobbyist prints a resin gear for a robot, but it breaks after 10 minutes of use—primary curing left it too brittle.

- Lösung: UV light secondary curing (405nm, 30 Minuten) strengthens the gear’s molecular bonds. The gear now lasts 500+ Minuten, with tensile strength increasing from 30 MPA zu 55 MPA.

2. Improves Surface Quality

- Problem: A jewelry maker prints a resin pendant, but it has visible layer lines that ruin its appearance—standard primary curing can’t smooth these out.

- Lösung: Heat curing (80° C, 2 Std.) softens the resin slightly, melting away layer lines. The pendant’s surface roughness (Ra) drops from 1.2 μm zu 0.4 μm, making it look professionally polished.

3. Unlocks Special Functions

- Problem: An engineer prints a resin sensor housing, but it can’t conduct electricity—primary curing only gives it basic structural strength.

- Lösung: During heat curing, conductive particles (Z.B., carbon black) are integrated into the resin. The cured housing now acts as a conductive shield, protecting the sensor from electromagnetic interference.

Step-by-Step Guide to Successful Secondary Curing

Follow this linear process to avoid mistakes like over-curing or uneven results—each step builds on the last to ensure quality:

- Prepare the Printed Part

- Stützstrukturen entfernen: Use pliers or a hobby knife to carefully take off supports (avoid bending the part).

- Clean excess resin: Spülen Sie den Teil in Isopropylalkohol aus (90%+ Konzentration) for 5–10 minutes—residue prevents even curing.

- Dry thoroughly: Pat the part with a lint-free cloth or air-dry it for 15 Minuten (moisture disrupts light/heat absorption).

- Choose the Right Curing Method

- Verwenden light curing Wenn: You’re working with SLA/DLP resins, need fast results, or want to improve surface smoothness.

- Verwenden heat curing Wenn: You’re using high-temperature resins, need to boost heat resistance, or have thick/large parts.

- Set Optimal ParametersRefer to this parameter guide for common materials:Material TypeCuring MethodLight Wavelength (gegebenenfalls)Temperatur (gegebenenfalls)Curing TimeStandard SLA ResinUV Light405nmN/A20–40 minsHigh-Temperature ResinHeatN/A100–120°C1–3 hoursConductive ResinHeat + Light365nm90°C45 mins

- Execute Curing & Überprüfen

- For light curing: Place the part in a UV curing chamber, ensuring all surfaces are exposed (rotate halfway through if needed).

- For heat curing: Use a temperature-controlled oven (avoid household ovens—they have uneven heat). Monitor with a thermometer to prevent overheating.

- Inspect the part: Überprüfen Sie auf Risse (sign of over-curing) or soft spots (under-curing). If flawed, adjust parameters and retry with a test part.

Critical Considerations to Avoid Mistakes

Secondary curing has pitfalls—here are 4 key tips to keep your parts in top shape:

- Prevent Over-Curing

- Over-curing breaks down polymer bonds, making parts brittle. Zum Beispiel: UV curing a standard resin for 2 Std. (anstatt 30 Minuten) reduces its toughness by 40%.

- Fix: Set timers and follow material guidelines—never exceed recommended curing times.

- Match Light Wavelength to Material

- Different resins need specific wavelengths: 405nm for most standard resins, 365nm for high-performance resins. Using the wrong wavelength (Z.B., 365nm for a 405nm resin) results in under-curing.

- Fix: Check the resin’s datasheet for recommended wavelength—invest in a multi-wavelength UV chamber for versatility.

- Ensure Safe Operation

- UV light risks: Direct exposure can burn skin and damage eyes—wear UV-protective gloves and goggles.

- Heat risks: High temperatures can melt plastic tools or start fires—keep the curing area clear of flammables (Z.B., Papier, alcohol).

- Testen Sie zuerst mit kleinen Teilen

- Before curing a large/valuable part, test parameters on a small scrap piece. Zum Beispiel: If you’re heat curing a $50 resin bracket, first cure a 2cm×2cm test cube—this lets you adjust temperature/time without wasting the bracket.

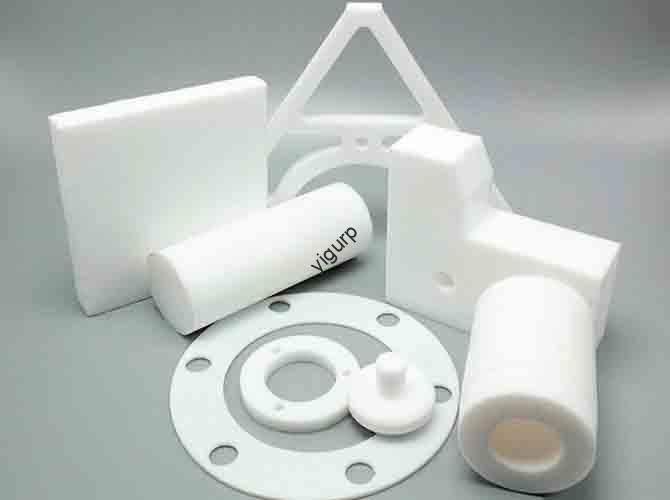

Perspektive der Yigu -Technologie

Bei Yigu Technology, Wir sehen3D printing secondary curing as the “final step to perfection” for resin parts. Our all-in-one curing systems combine UV light (365nm/405nm) und Hitze (50–150 ° C.) functions, with smart sensors that auto-adjust parameters based on material type. We’ve helped clients—from jewelry makers to aerospace engineers—boost part durability by 60% and cut curing time by 30%. As resin technology advances, we’re adding AI-driven parameter suggestions to our systems—soon, they’ll analyze your part’s size/material and recommend the ideal curing setup, making professional results accessible to everyone.

FAQ

- Q: Can I use a household UV lamp for secondary curing?A: Ja, but only for small parts. Household lamps (Z.B., blacklights) have uneven light distribution—large parts may cure unevenly. Für beste Ergebnisse, use a dedicated UV curing chamber (they ensure consistent exposure).

- Q: How do I know if a part is over-cured?A: Signs include brittleness (breaks easily when bent), Verfärbung (turns yellow/brown), or warping (misshapes from heat). Wenn Sie diese sehen, reduce curing time by 20% or lower temperature by 10°C for the next part.

- Q: Do FDM prints need secondary curing?A: Rarely—FDM uses thermoplastics that melt and solidify during printing, so primary cooling is usually enough. Jedoch, some FDM materials (Z.B., ABS) can benefit from heat curing (80° C, 1 Stunde) Warping reduzieren.