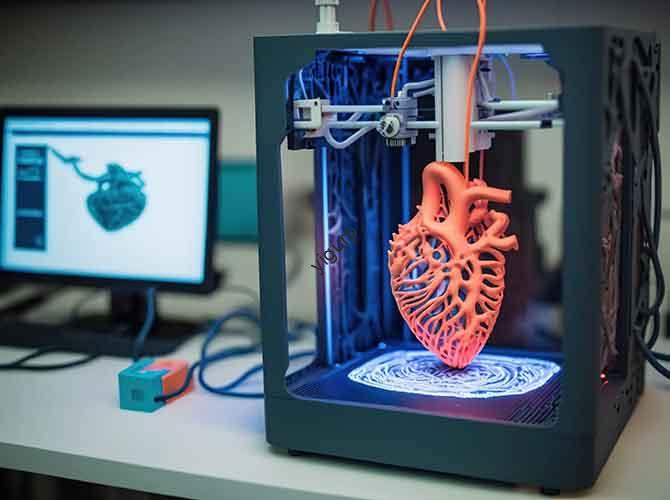

Why are artists, Designer, and cultural institutions turning to 3D printing crafts? Unlike traditional handmade crafts that rely on skill and time, 3D printing transforms digital ideas into physical art with unmatched flexibility—solving pain points like limited design scope, langsame Produktion, and difficulty replicating complex details. This article breaks down how 3D printing works for crafts, seine wichtigsten Vorteile, reale Verwendungen, und Tipps, um häufige Fehler zu vermeiden, helping you unlock new creative possibilities.

How Does 3D Printing Crafts Work?

Im Kern, 3D printing crafts follow a 4-step linear process that turns virtual designs into tangible art. Each step is critical—skip one, and you risk flawed results:

- Digital Modeling: Create a 3D model using software like Tinkercad (Anfänger-freundlich) oder Mixer (fortschrittlich). For cultural heritage projects, use 3D scanners to capture existing relics (Z.B., a broken ceramic vase) into digital files.Für die Spitze: Add fine details (Z.B., patterns on a sculpture) in the model—3D printing can reproduce even 0.1mm-wide lines.

- Schneiden: Convert the 3D model into layer-by-layer instructions using slicing software (Z.B., Behandlung). Set parameters like layer height (0.1–0.2mm for smooth finishes) and infill (10–50% for crafts—higher infill = sturdier pieces).

- Drucken: Load the sliced file into a 3D printer and select the right material (Kunststoff, Keramik, or biodegradable filaments). The printer deposits material layer by layer—for example, a small decorative lamp takes 4–6 hours to print.

- Nachbearbeitung: Refine the printed piece to enhance its look and feel:

- Sand rough edges with 200–400-grit sandpaper.

- Paint with acrylics or apply varnish for a glossy finish.

- For ceramic crafts, fire the printed piece in a kiln (1200–1300°C) to harden it.

3D Printing Crafts vs. Traditional Handmade Crafts: A Clear Comparison

Many creators wonder: “Is 3D printing better than traditional crafting?” The answer depends on your goals—but 3D printing solves key limitations of manual work. Here’s a side-by-side contrast:

| Aspekt | 3D Printing Crafts | Traditional Handmade Crafts |

|---|---|---|

| Designfreiheit | Can create complex shapes (Z.B., hollow sculptures with internal patterns) that are impossible to carve by hand. | Limited by physical tools and human skill—complex details often require years of practice. |

| Produktionsgeschwindigkeit | A small souvenir takes 4–8 hours; 10 identical pieces take ~10 hours (with multiple printers). | One small souvenir takes 1–2 days; 10 identical pieces take 10–20 days. |

| Konsistenz | Every printed piece is identical (Toleranz ± 0,1 mm)—ideal for 批量 gifts or exhibitions. | Variations between pieces are common (Z.B., slight differences in a hand-painted mug). |

| Materialoptionen | Works with plastics (PLA, ABS), Keramik, wood-based filaments, and even biodegradable materials. | Relies on traditional materials (clay, Holz, Metall) that may be hard to source or shape. |

Key Benefits of 3D Printing Crafts (And How They Solve Problems)

3D printing isn’t just a “trend”—it solves real challenges for crafters, Künstler, and cultural organizations. Hier sind 4 core benefits with concrete examples:

1. Unübertroffene Designflexibilität

- Problem: A sculptor wants to create a statue with interlocking parts (no glue needed) but can’t carve the delicate connections by hand.

- Lösung: 3D print the statue with pre-designed interlocking joints—each part fits perfectly, and the design would be impossible to replicate manually.

2. Cost-Effective Small-Batch Production

- Problem: A small business wants to make 50 custom wedding favors (Z.B., personalized keychains) but can’t afford the time or labor for handmade pieces.

- Lösung: 3D print 50 keychains in 2 Tage (Verwendung 2 Drucker) at a cost of $2–$3 per piece—vs. $10–$15 per handmade keychain.

3. Cultural Heritage Preservation

- Problem: A museum has a fragile ancient pottery shard that can’t be displayed publicly (risk of breaking) and needs a replica for exhibitions.

- Lösung: 3D scan the shard, repair cracks in the digital model, then print an exact replica—visitors can view the replica, and the original is safely stored.

4. Sustainable Crafting

- Problem: A crafter wants to reduce waste (traditional crafting often leaves leftover materials like scrap wood or clay).

- Lösung: Use biodegradable PLA filament for 3D printing—leftover material can be melted and reused, and printed pieces decompose in 6–24 months if composted.

Real-World Applications of 3D Printing Crafts

From home decor to cultural preservation, 3D printing crafts are making an impact across industries. Hier sind 3 inspiring use cases:

- Wohnkultur: A designer in Paris created 3D printed lamp shades with floral patterns that change color when lit. The complex lattice structure (0.5mm dünn) würde nehmen 20+ hours to make by hand—3D printing takes 5 Std..

- Souvenirs & Geschenke: For a music festival, a team printed custom guitar pick souvenirs with attendees’ names. Sie produzierten 500 picks in 3 Tage, Und 95% of attendees said the personalized gift made the festival more memorable.

- Cultural Restoration: The Vatican Museums used 3D printing to restore a broken 16th-century marble statue. They scanned the remaining pieces, rebuilt missing parts (Z.B., a cracked hand) in the digital model, then printed the hand in stone-composite material—visitors can’t tell the difference between the original and the 3D printed part.

Perspektive der Yigu -Technologie

Bei Yigu Technology, Wir glauben3D printing crafts are bridging the gap between tradition and innovation. Our 3D printers are optimized for craft creators: they support multiple materials (from PLA to ceramics), have a user-friendly interface (no technical expertise needed), and include safety features (Z.B., overheat protection) for home use. We’ve helped small businesses cut craft production time by 60% and cultural institutions preserve 200+ fragile relics. As materials improve (Z.B., silk-based filaments for luxury crafts), we’ll keep making 3D printing more accessible—so every creator can turn their ideas into art.

FAQ

- Q: What’s the cost of getting started with 3D printing crafts?A: A beginner-friendly 3D printer costs $200–$500, and PLA filament (the most common material for crafts) is $20–$30 per spool (enough for 5–10 small pieces). No extra tools are needed—just a laptop for modeling software (many free options exist).

- Q: Can 3D printing crafts match the “handmade” feel that many people love?A: Ja! Nachbearbeitung (Sandpapier, Malerei, hand-finishing) adds a tactile, artisanal touch. Many 3D printed crafts are mistaken for handmade—for example, 3D printed ceramic mugs with hand-painted designs.

- Q: How long does it take to learn 3D printing for crafts?A: Beginners can learn to create simple crafts (Z.B., ein Schlüsselbund) in 1–2 Wochen. Mastering komplexe Designs (Z.B., Skulpturen) takes 1–3 months, but free online tutorials (YouTube, Tinkercad’s lessons) speed up the process.