Wenn Sie schon einmal mit langsamen Design-Iterationen konfrontiert waren, hoher Materialabfall, or inconsistent print quality in 3D manufacturing—whether for prototypes or mass-produced parts—3D printing artificial intelligence (KI) ist deine Lösung. Diese leistungsstarke Kombination vereint die Analyse- und Optimierungsfähigkeiten der KI mit der additiven Flexibilität des 3D-Drucks, Aber wie integriert man sie effektiv?? Welche Branchen profitieren am meisten?? And how can you overcome challenges like data security or tech compatibility? Dieser Ratgeber beantwortet alle diese Fragen, helping you leverage 3D-Druck AI for efficient, hochwertige Ergebnisse.

What Is 3D Printing Artificial Intelligence?

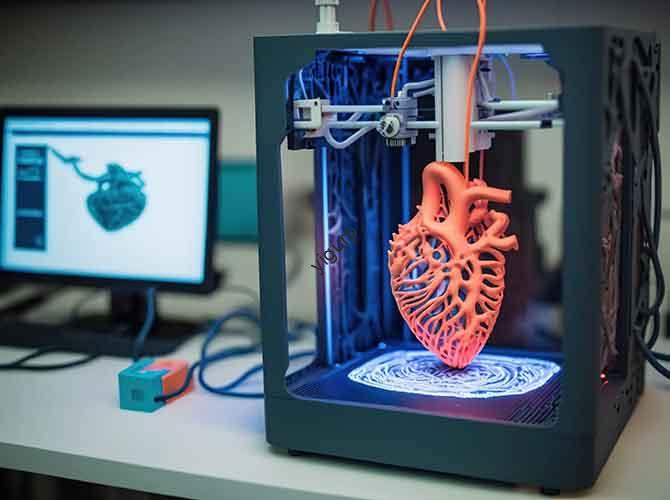

3D printing artificial intelligence refers to the integration of AI technologies—such as machine learning, computer vision, and predictive analytics—into the 3D printing workflow. Im Gegensatz zum herkömmlichen 3D-Druck (which relies on manual design tweaks and trial-and-error), AI acts as a “smart assistant”: it optimizes designs, refines print paths, and detects errors in real time.

Think of it like a chef with a smart kitchen: the chef (designer/manufacturer) creates a recipe (3D model), and the smart kitchen (KI) adjusts cooking time/temperature (print settings) to avoid burning, suggests ingredient substitutions (material tweaks) for better flavor, and alerts the chef if a tool is broken (error detection). For 3D printing, this means faster, more reliable production with less waste.

Key roles of AI in 3D printing:

- Design optimization: AI learns from thousands of designs to improve part strength, Gewicht reduzieren, and eliminate unnecessary material.

- Print path optimization: AI algorithms rearrange print paths to cut time and waste (z.B., avoiding redundant movements).

- Qualitätsprüfung: AI uses computer vision to spot defects (like layer separation) during printing—before they ruin the part.

Step-by-Step Workflow of 3D Printing Artificial Intelligence

Integrating AI into 3D printing follows a linear, repeatable process that enhances every stage. Nachfolgend finden Sie eine detaillierte Aufschlüsselung, from design to post-print analysis:

- AI-Powered Design Creation & Optimierung

- Start with a basic 3D model in CAD-Software (z.B., SolidWorks). Import the model into an AI design tool (z.B., Autodesk Generative Design).

- AI analyzes the model’s intended use (z.B., “this part needs to support 10kg of weight”) and generates 5-10 optimized designs. Zum Beispiel:

- It may add lattice structures to reduce weight by 30% without losing strength.

- It may remove overhangs to eliminate the need for supports (cutting post-processing time).

- Export the optimized model as an STL-Datei—now ready for slicing.

- AI-Driven Slicing & Print Path Optimization

- Upload the STL file to an AI-enabled slicer (z.B., Ultimaker Cura with AI plugins).

- AI does three critical things:

- Material matching: It recommends the best material (z.B., “use PETG for this outdoor part”) based on the model’s specs.

- Parameter tuning: It sets print speed (z.B., 55mm/s for PLA), Schichthöhe (0.15mm), and infill (60%) to minimize waste and maximize quality.

- Path optimization: It rearranges the print path to reduce travel time—cutting overall print time by 15-20%.

- Real-Time AI Monitoring During Printing

- Start the 3D printer (equipped with cameras or sensors). AI uses computer vision to monitor the print:

- It alerts you if the material runs low (z.B., “PLA cartridge will empty in 10 minutes”).

- It pauses the print if it detects a defect (z.B., “layer separation at 5mm height—check bed adhesion”).

- For industrial printers, AI even adjusts parameters mid-print (z.B., “increasing bed temperature by 5°C to fix warping”).

- Start the 3D printer (equipped with cameras or sensors). AI uses computer vision to monitor the print:

- AI-Powered Post-Print Inspection & Analysis

- Nach dem Drucken, scan the part with a 3D scanner. AI compares the scanned part to the original model:

- It checks for dimensional errors (z.B., “the hole is 0.1mm smaller than designed”).

- It rates surface quality (z.B., “95% of the part is smooth—only minor layer lines on the bottom”).

- AI generates a report with fixes (z.B., “increase hole size by 0.1mm in the next print”)—helping you refine future projects.

- Nach dem Drucken, scan the part with a 3D scanner. AI compares the scanned part to the original model:

3D Printing AI: Anwendungen & Industry Benefits

AI transforms 3D printing use cases across industries. Below is a table highlighting key applications, AI’s role, and tangible benefits:

| Industrie | Anwendung | How AI Enhances 3D Printing | Real-World Benefit |

|---|---|---|---|

| Medizinisch | Maßgeschneiderte Prothetik & chirurgische Führungen | AI analyzes patient scans (z.B., MRI of a leg) to design prosthetics that fit perfectly; it inspects surgical guides for defects. | Prosthetic fit accuracy improves by 40%; surgery time reduces by 25% (no guesswork with guides). |

| Automobil | Prototyping & small-batch parts | AI optimizes car part designs (z.B., “lightweight this bracket by 25%”); it monitors production to ensure consistency. | Prototype development time cuts from 2 Wochen bis 3 Tage; part defect rate drops from 8% Zu 2%. |

| Luft- und Raumfahrt | High-stress components (z.B., Motorteile) | AI tests designs for extreme conditions (z.B., “will this part survive 150°C heat?”); it uses predictive analytics to prevent tool wear. | Part weight reduces by 35% (saving fuel); tool replacement costs drop by 20%. |

| Konsumgüter | Personalized products (z.B., Handyhüllen) | AI generates custom designs based on user input (z.B., “add a logo here”); it optimizes print paths for mass customization. | Customization time cuts from 1 hour to 10 Minuten; production of 100 unique cases takes 5 Std. (vs. 10 hours manually). |

Vorteile & Challenges of 3D Printing Artificial Intelligence

Like any tech combination, 3D printing AI has strengths and limitations. Below is a balanced breakdown to help you set expectations:

Vorteile (Why It’s Worth Investing In)

- Schnellere Markteinführung: AI cuts design and print time by 20-30%—a product that took 1 month to prototype now takes 3 Wochen.

- Lower costs: AI reduces material waste by 25-35% (z.B., using 70g of PLA instead of 100g for a part) and eliminates failed prints (sparen $50-$100 per failed attempt).

- Better quality: AI ensures consistency—95% of parts meet specs (vs. 80% with manual 3D printing).

Herausforderungen (And How to Overcome Them)

- Data privacy & security: AI relies on design and print data—if hacked, competitors could steal your designs.Lösung: Use encrypted AI tools (z.B., cloud-based platforms with end-to-end encryption); avoid sharing sensitive data with third-party AI services.

- Tech compatibility: Older 3D printers may not work with AI tools (z.B., no camera for monitoring).Lösung: Upgrade to entry-level AI-enabled printers (z.B., Creality Ender 5 S1 with AI plugins) für $500-$1,000; or add external sensors (z.B., a Raspberry Pi camera) to older models.

- Learning curve: AI tools can be complex for beginners—setting up generative design may take 1-2 Wochen.Lösung: Use user-friendly AI tools (z.B., Tinkercad with AI design assistants); take free online courses (z.B., Autodesk’s Generative Design 101) to learn basics.

Real-World Case Studies of 3D Printing AI

3D printing AI is already revolutionizing manufacturing. Below are specific examples of its impact:

1. Medizinisch: Custom Knee Implants

A hospital wanted to create custom knee implants for 50 Patienten. They used:

- 3D printing AI: AI analyzed each patient’s CT scan to design implants that matched bone structure; AI-monitored printers ensured no defects.

- Ergebnis:

- Implant fit accuracy improved by 45%—patients reported less pain post-surgery.

- Design time per implant dropped from 8 Stunden bis 1 Stunde; print time cut by 20%.

- No failed prints (vs. 5 failed attempts with manual 3D printing)—saving $2,500 in material costs.

2. Automobil: Electric Vehicle (EV) Bracket Prototyping

An EV manufacturer needed to prototype a battery bracket (weight goal: under 2kg, strength goal: support 50kg). They used:

- 3D printing AI: AI generated 8 optimized bracket designs; it optimized print paths to use 25% less ABS plastic.

- Ergebnis:

- The final bracket weighed 1.8kg (met weight goal) and supported 55kg (exceeded strength goal).

- Prototyping time cut from 14 Tage bis 4 days—letting the team test 3 iterations instead of 1.

- Material costs dropped by $300 per prototype.

3. Luft- und Raumfahrt: Satellite Component Manufacturing

A space company needed to print a satellite antenna bracket (must withstand launch vibrations). They used:

- 3D printing AI: AI simulated launch conditions to test the bracket; it monitored printing to prevent defects.

- Ergebnis:

- The bracket survived vibration tests (10g force)—no cracks or deformation.

- Print time reduced by 18%; defect rate dropped to 0% (vs. 10% with manual printing).

- The bracket was 40% lighter than the traditionally machined version—saving $10,000 in launch costs (lighter satellites cost less to launch).

Future Trends of 3D Printing Artificial Intelligence

As AI and 3D printing evolve, their combination will become even more powerful. Here are three trends to watch:

- AI-Generated Full Product Designs: Soon, AI will create entire product designs from a single prompt (z.B., “design a lightweight bike frame for a 70kg rider”). No more basic CAD models—AI will handle the entire design process.

- AI-Driven Material Innovation: AI will develop new 3D printing materials (z.B., “a biodegradable PLA that’s 2x stronger”). It will analyze material properties (z.B., “this polymer melts at 180°C”) and mix ingredients to create tailored materials.

- Decentralized AI 3D Printing: AI will connect 100+ small 3D printers (z.B., in a city) to act as a single “virtual factory.” If one printer is busy, AI sends the job to another—cutting lead times for local manufacturing.

Yigu Technology’s Perspective on 3D Printing Artificial Intelligence

Bei Yigu Technology, we believe3D printing artificial intelligence is the future of smart manufacturing. Our AI-enabled 3D printers (z.B., Yigu Tech AI-F5) come with built-in computer vision for real-time monitoring and AI slicing tools that optimize print paths. We also offer a cloud-based AI design platform—users can upload basic models and get optimized versions in 10 Minuten. For small businesses, we provide free AI training workshops to reduce the learning curve. 3D printing AI isn’t just about tech—it’s about helping users make better parts, Schneller, for less money.

FAQ: Common Questions About 3D Printing Artificial Intelligence

- Q: Do I need expensive hardware to use 3D printing AI?A: NEIN! Entry-level AI tools (z.B., free plugins for Cura) work with most desktop printers (z.B., Creality Ender 3). Für den industriellen Einsatz, you may need printers with sensors, but small businesses can start with basic AI software for $0-$50 per month.

- Q: Can AI fix a bad 3D model (z.B., one with gaps or overlapping faces)?A: Ja! Most AI design tools (z.B., Autodesk Generative Design) automatically repair minor model errors (z.B., filling small gaps). For major errors (z.B., overlapping faces), AI will flag the issue and suggest fixes (z.B., “simplify this section of the model”).

- Q: Is 3D printing AI suitable for hobbyists, or is it only for industrial users?A: It’s for everyone! Hobbyists can use AI to design custom toys (z.B., “AI generate a dinosaur with movable legs”) or fix print failures (z.B., “why is my part warping?”). Industrial users benefit from mass production optimization, but hobbyists get just as much value from AI’s design and troubleshooting help.