Our CNC Engraving Services

Elevate your projects with custom CNC engraving services from Yigu Technology—where cutting-edge CNC engraving technology meets uncompromising precision. Whether you need intricate designs on metal, plastic, or wood, our advanced processes deliver consistent quality, tight tolerances, and fast turnaround times. From automotive parts to medical devices, we turn your ideas into reality with expertise that outperforms traditional methods. Choose reliability, choose customization, choose Yigu for your CNC engraving needs.

What Is CNC Engraving?

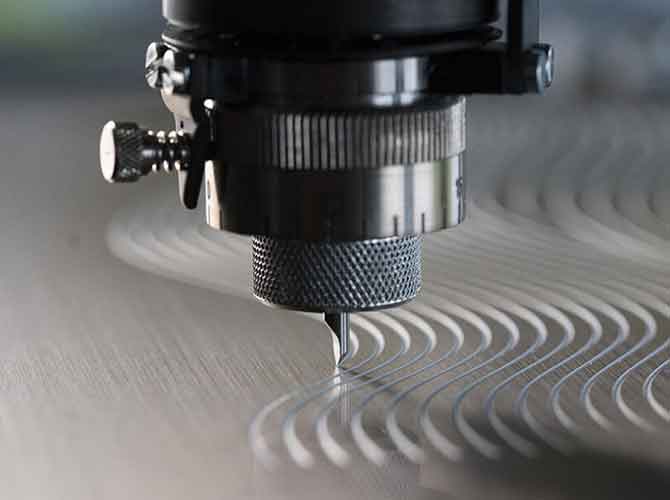

CNC engraving (Computer Numerical Control engraving) is a precision manufacturing process that uses computerized systems to control engraving tools, creating detailed designs, text, or patterns on various materials. Unlike traditional engraving, which relies on manual skill and is prone to human error, CNC engraving technology uses pre-programmed software to ensure repeatability and accuracy—making it ideal for both small-batch prototypes and large-scale production.

At its core, CNC engraving machine principles involve translating digital designs into toolpaths, which guide the engraving tool (such as a router or laser) to cut, carve, or mark the material surface. Key benefits of this approach include precision CNC engraving (with tolerances as tight as ±0.001 inches) and versatility across industries. Below is a quick comparison of CNC engraving vs. traditional engraving:

| Feature | CNC Engraving | Traditional Engraving |

| Accuracy | ±0.001–±0.005 inches | ±0.01–±0.05 inches |

| Repeatability | 100% consistent across batches | Depends on operator skill |

| Speed | 2–5x faster for complex designs | Slower for intricate patterns |

| Material Compatibility | Metals, plastics, wood, acrylic, etc. | Limited to softer materials (often) |

| Customization | Easy to adjust digital designs | Requires retooling for new designs |

Our CNC Engraving Capabilities: What We Can Do for You

At Yigu Technology, our CNC engraving capabilities are designed to meet the diverse needs of modern industries. We offer a full range of CNC engraving services, from simple text marking to complex 3D carving, with a focus on quality, speed, and customization.

| Capability | Details |

| CNC Engraving Precision | Achieve tolerances of ±0.001 inches for high-precision parts. |

| Material Compatibility | Work with metals (aluminum, brass, stainless steel), plastics (polycarbonate), wood, and acrylic. |

| Surface Finish Options | Offer polishing, plating, anodizing, and texturing for a professional look. |

| Speed & Efficiency | Complete small batches in 1–2 days; large-scale production in 5–7 days. |

| Customization | Accept CAD files and hand-drawn designs to create unique engravings. |

The CNC Engraving Process: From Design to Delivery

Our CNC engraving process is streamlined to ensure efficiency without compromising quality. Each project follows a clear workflow, from initial design to final quality control.

- Design Consultation: We review your design (CAD files or sketches) to confirm feasibility and suggest optimizations for CNC engraving toolpath generation.

- Software Setup: Our team uses advanced CNC engraving software (such as AutoCAD and Mastercam) to convert your design into machine-readable code.

- Machine Calibration: We calibrate our CNC machines to match your project’s requirements—adjusting tool speed, depth, and material fixturing for optimal results.

- Engraving Execution: The machine follows the pre-programmed toolpaths to perform CNC engraving cutting or marking on the selected material.

- Post-Processing: After engraving, we conduct CNC engraving post-processing (e.g., polishing, cleaning, or coating) to enhance the final product’s appearance and durability.

- Quality Control: Every part undergoes rigorous CNC engraving quality control—using precision measuring tools (calipers, micrometers) to verify dimensions and tolerances.

Delivery: Approved products are packaged securely and shipped to your location, with full project documentation provided.

Compatible Materials for CNC Engraving

Choosing the right material is critical for successful CNC engraving. Yigu Technology works with a wide range of CNC engraving compatible materials, each selected for its durability, machinability, and aesthetic appeal. Below is a breakdown of our most popular materials:

| Material Type | Examples | Best For | Engraving Characteristics |

| Metals | Aluminum, brass, stainless steel | Automotive parts, medical devices, jewelry | High precision; produces clean, sharp edges |

| Plastics | Polycarbonate, acrylic | Signage, electronics enclosures | Lightweight; easy to engrave complex designs |

| Wood | Oak, maple, plywood | Decorative items, furniture accents | Creates natural, textured finishes |

| Composite Materials | Fiberglass, carbon fiber | Aerospace components, industrial parts | High strength; requires specialized tools |

Surface Treatment Options for CNC Engraved Parts

CNC engraving surface treatment is essential to enhance the functionality and appearance of your parts. We offer a variety of finishing processes to meet your specific needs:

- Polishing: Creates a smooth, reflective surface—ideal for metal parts like jewelry or decorative components.

- Anodizing: Adds a protective oxide layer to aluminum parts, improving corrosion resistance and color options (black, silver, gold).

- Plating: Coats parts with metals like nickel or chrome for increased durability and a sleek, professional look.

- Painting: Applies high-quality paints to match brand colors or provide additional protection against wear.

- Texturing: Creates non-slip or decorative surfaces (e.g., knurling on tool handles) for improved grip or aesthetics.

Laser Marking: Uses laser technology for permanent, high-contrast markings on metals and plastics—perfect for serial numbers or logos.

CNC Engraving Tolerances: Ensuring Precision You Can Trust

CNC engraving tolerances refer to the acceptable deviation from the intended dimensions of a part. At Yigu Technology, we prioritize CNC engraving accuracy to meet the strict standards of industries like aerospace and medical manufacturing.

Our tolerance capabilities vary by material and project complexity, but we consistently achieve:

- Tight tolerances of ±0.001 inches for high-precision applications (e.g., medical device components).

- Dimensional accuracy of ±0.005 inches for general industrial parts (e.g., automotive brackets).

- Repeatability of 99.9% across batches—ensuring every part matches your design.

To maintain these standards, we use CNC engraving measurement techniques such as coordinate measuring machines (CMMs) and optical comparators, along with strict quality assurance protocols.

Advantages of CNC Engraving Services

Choosing CNC engraving services over traditional methods offers numerous benefits for businesses across industries:

- Precision Advantages: CNC engraving precision eliminates human error, ensuring parts meet exact specifications—critical for industries like aerospace and medical.

- Speed Benefits: CNC machines operate 24/7 with minimal downtime, reducing project lead times by 50% compared to traditional engraving.

- Cost-Effectiveness: While initial setup costs are higher, CNC engraving cost-effectiveness shines in high-volume production—lowering per-unit costs by 30–40%.

- Customization Benefits: Easy to adjust digital designs, allowing for quick changes to prototypes or custom orders without retooling.

- Versatility: Works with a wide range of materials and can handle complex designs (e.g., 3D engravings) that traditional methods cannot.

Environmental Benefits: Reduces material waste by 20–30% through precise toolpath planning, and uses energy-efficient machines.

CNC Engraving Applications by Industry

CNC engraving applications span nearly every industry, thanks to its versatility and precision. Below are some of the most common uses:

| Industry | Applications |

| Automotive | Engraving serial numbers on engine parts, decorative trim, and dashboard components. |

| Aerospace | Precision marking on turbine blades, aircraft brackets, and avionics parts. |

| Electronics | Engraving logos on circuit boards, USB drives, and smartphone cases. |

| Medical Devices | Marking patient ID numbers on implants, surgical tools, and diagnostic equipment. |

| Jewelry | Intricate 3D engravings on rings, necklaces, and bracelets. |

| Signage & Advertising | Creating custom signs for businesses, event banners, and promotional items. |

| Manufacturing | Prototyping parts, engraving tooling, and batch production of components. |

CNC Engraving Manufacturing Techniques

At Yigu Technology, we use a range of CNC engraving manufacturing techniques to optimize results for different materials and designs:

- CNC Milling: Uses rotating cutting tools to remove material from the workpiece—ideal for 3D engravings and complex shapes.

- CNC Routing: Uses a high-speed router to carve deep, wide grooves—perfect for wood and plastic signage.

- Laser Engraving: Uses a laser beam to mark or cut materials—excellent for high-contrast, detailed markings on metals and plastics.

- Drilling: Creates precise holes in parts, often used in conjunction with engraving for electronics or mechanical components.

- Hybrid Techniques: Combines two or more methods (e.g., milling + laser marking) to achieve complex results for specialized projects.

Tool selection is also critical—we use carbide tools for metals, high-speed steel (HSS) tools for plastics, and diamond-tipped tools for ultra-hard materials like stainless steel.

CNC Engraving Case Studies: Real-World Success Stories

Nothing showcases the power of CNC engraving services better than real-world results. Below are three detailed CNC engraving case studies—spanning automotive, medical, and signage industries—that highlight our ability to solve complex challenges, boost efficiency, and deliver exceptional quality. Each story includes CNC engraving project examples, customer feedback, and insights into how we turned goals into reality.

Case Study 1: Automotive Parts Engraving – Boosting Traceability for a Global Manufacturer

Project Background

A leading global automotive supplier approached Yigu Technology with a critical need: to engrave unique serial numbers and part IDs on 5,000 aluminum engine brackets per month. Their previous traditional engraving process was slow (taking 2 minutes per part) and error-prone—resulting in 3% of parts being rejected due to unreadable markings. This delayed production and increased costs.

Our Solution

We recommended laser CNC engraving—a faster, more durable method than their previous manual process. Our team:

- Programmed custom toolpaths using Mastercam software to match their part designs.

- Calibrated a 5-axis CNC laser machine to engrave serial numbers with ±0.002-inch accuracy.

- Implemented a automated feeding system to handle high-volume production.

Results

- Efficiency: Engraving time dropped from 2 minutes to 15 seconds per part—a 75% speed increase (aligning with CNC engraving efficiency case studies goals).

- Quality: Rejection rate fell to 0.1% (from 3%), as laser markings were resistant to heat, oil, and corrosion.

Traceability: Every part now has a scannable QR code (engraved alongside the serial number) for easy tracking.

Why Choose Yigu Technology for CNC Engraving Services?

When you partner with Yigu Technology, you’re choosing a team with the expertise, technology, and commitment to deliver exceptional CNC engraving services. Here’s why clients trust us:

- Expertise: Our engineers have 10+ years of experience in CNC engraving technology, ensuring they can handle even the most complex projects.

- Quality: We adhere to strict CNC engraving quality assurance standards, with 99.8% of projects meeting or exceeding client specifications.

- Customer Service: Our team provides 24/7 support—from design consultation to post-delivery follow-up—to ensure your project runs smoothly.

- Innovation: We invest in the latest advanced CNC engraving technology (e.g., 5-axis machines) to offer cutting-edge solutions.

Value: We balance competitive pricing with high-quality results, delivering CNC engraving cost-effectiveness for both small and large projects.