Key Advantages of Replica Prototypes: Why They Matter for Your Project

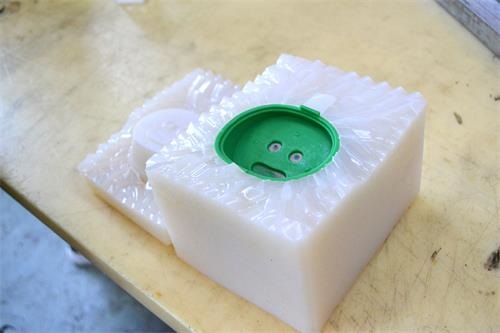

If you’re in product development, you’ve likely heard about replica prototypes—but do you know why they’ve become such a valuable tool for manufacturers and designers? Unlike traditional manufacturing methods that rely on expensive steel molds, replica prototypes use silicone molds to create multiple copies of a master model. This approach offers unique benefits that make […]