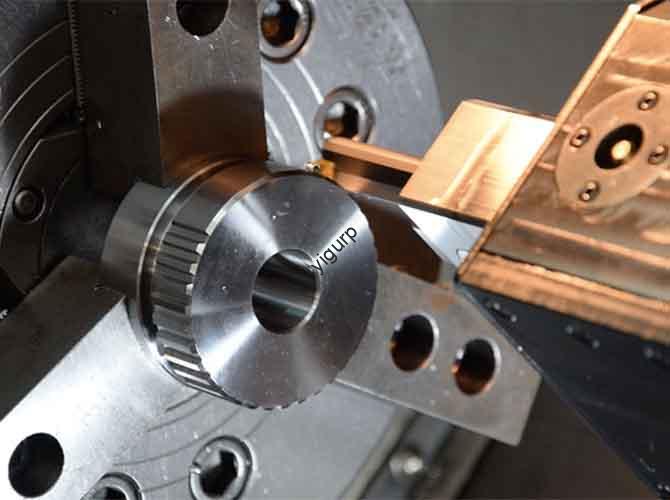

Precision Sheet Metal Prototype Parts Bending: Mastering Accuracy for Custom Prototypes

In product development, precision sheet metal prototype parts bending is not just a manufacturing step—it’s the bridge between design blueprints and functional, high-quality prototypes. Whether you’re creating a small electronic enclosure or a complex automotive component, getting the bending right ensures your prototype fits, performs, and meets every design standard. But how do you achieve […]