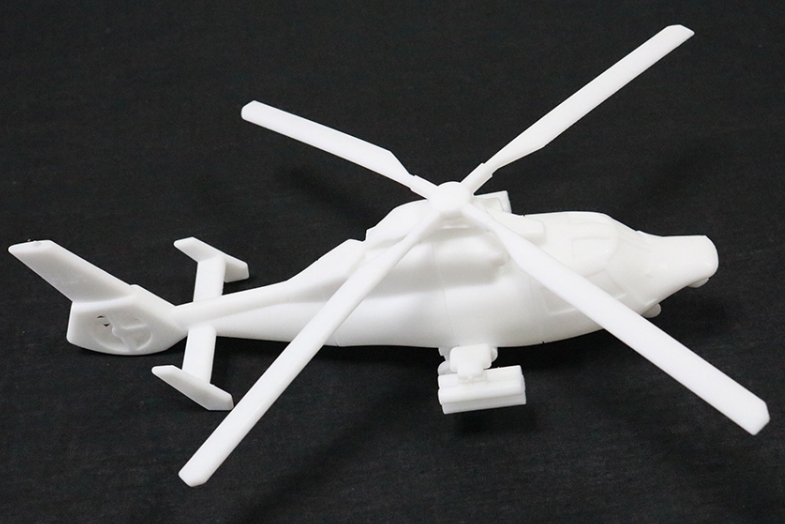

Prototype Model of the Soft Rubber Robot: Guide for Precision Manufacturing

In the fast-developing robotics industry, verifying design feasibility and functionality early is key to avoiding costly mistakes in mass production. The prototype model of the soft rubber robot is a game-changer—it lets engineers test flexible parts, simulate real working conditions, and collect reliable data at a lower cost. Whether you’re a procurement engineer selecting materials […]