How to Design and Produce High-Quality Hardware Shrapnel Prototypes?

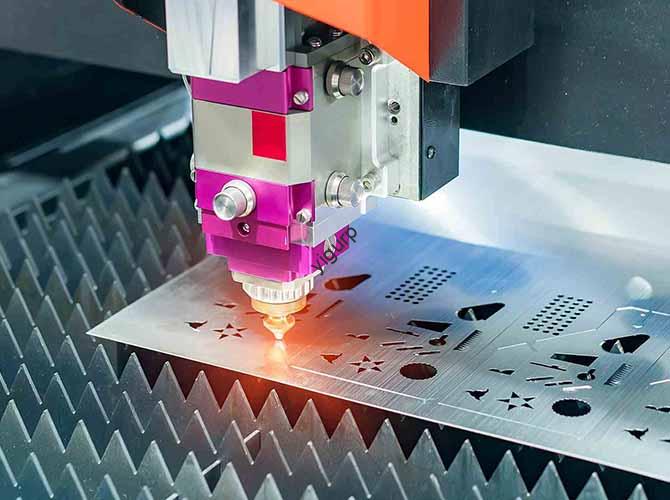

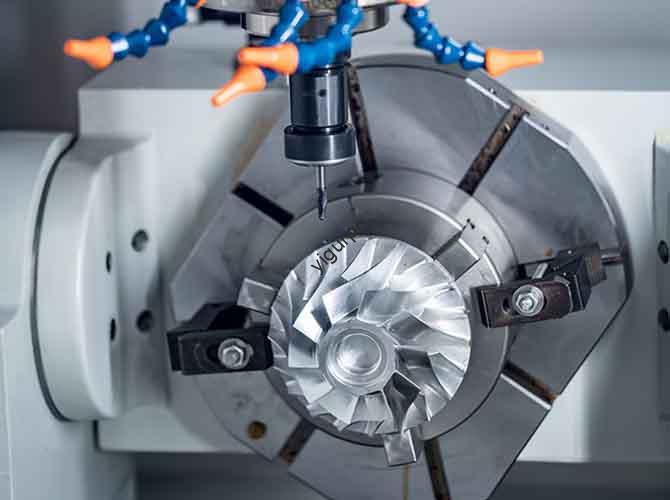

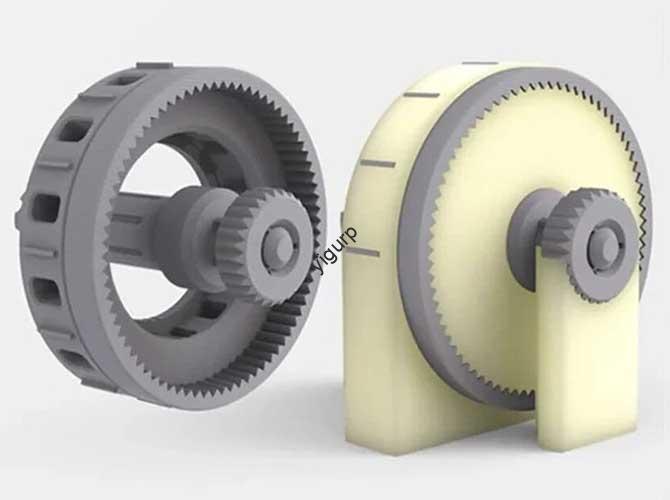

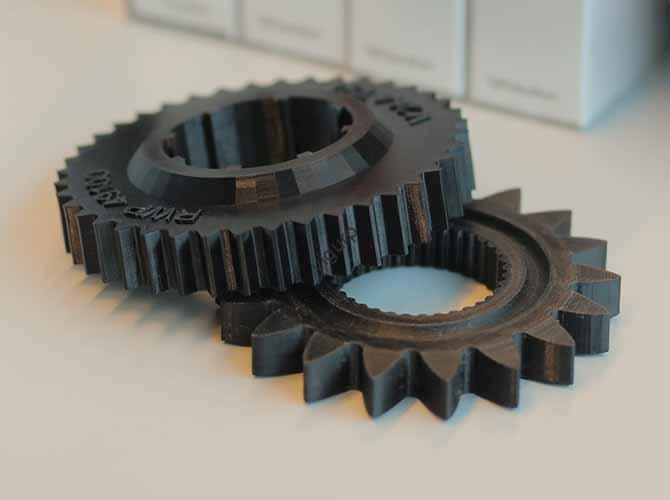

Hardware shrapnel prototypes are critical components in electronic devices, automotive parts, and industrial equipment—their elasticity, precision, and durability directly affect product performance. From material selection to testing validation, every link in the production process requires careful planning to meet functional and cost goals. This article systematically breaks down the core requirements, production processes, cost optimization, […]