PEEK Pipes: The Ultimate Guide for Industrial, Medical & Aerospace Use

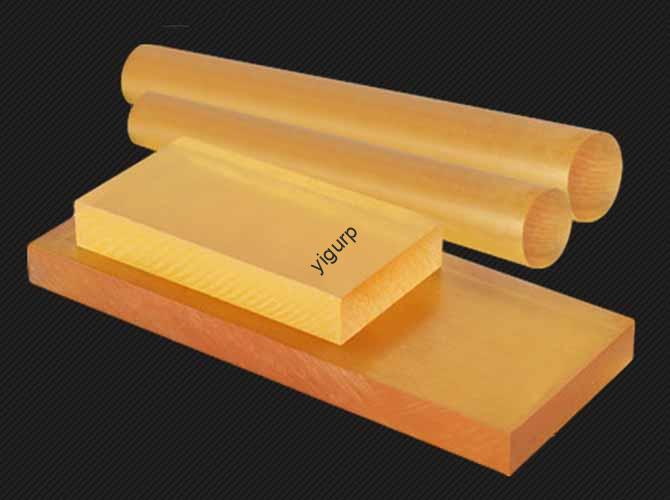

If you’re an engineer, manufacturer, or buyer wondering what PEEK pipes are and why they’re a game-changer for your industry, let’s get straight to the point. PEEK (short for Polyether Ether Ketone) is a high-performance thermoplastic, and PEEK pipes are hollow tubes made from this material—designed to handle extreme conditions that break down ordinary plastics or metals. […]