Miniature Injection Molding: The Complete Guide for Hobbyists & Small Businesses

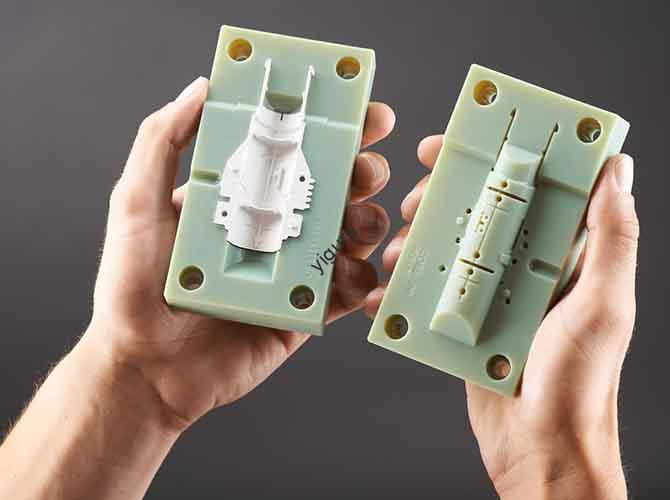

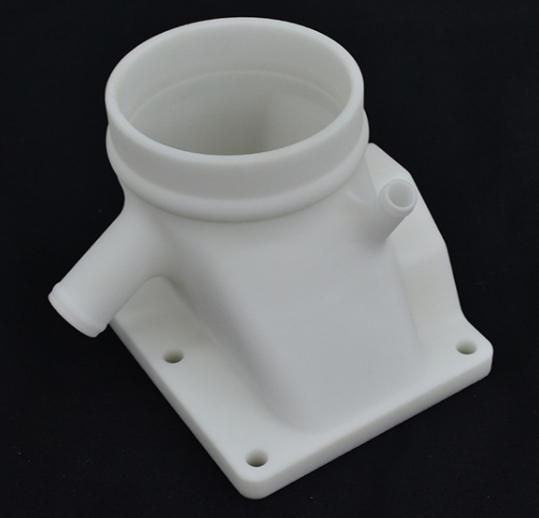

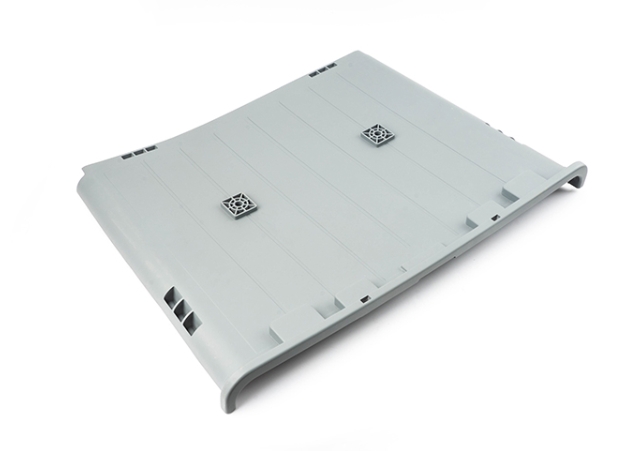

If you need to mass-produce small, precise plastic parts (think: tiny gears for a model robot, custom jewelry components, or micro-components for medical devices), miniature injection molding is the solution. Unlike 3D printing (which is great for prototypes but slow for large batches), this process uses scaled-down injection molding machines to inject molten plastic into small molds—creating […]