What Makes Precision Aluminum Die Casting a Core Process in Modern Manufacturing?

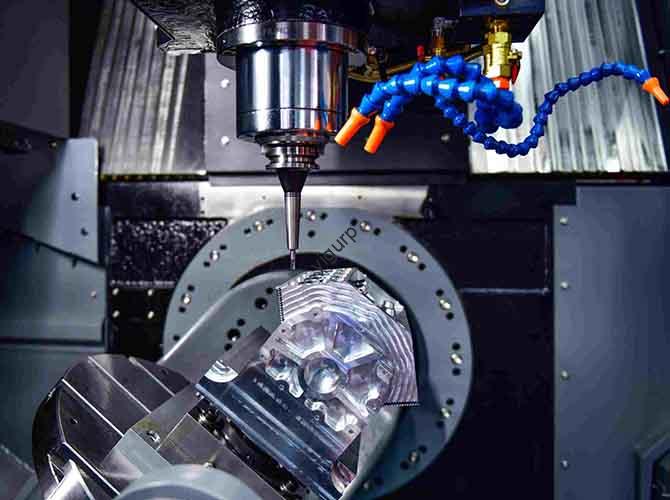

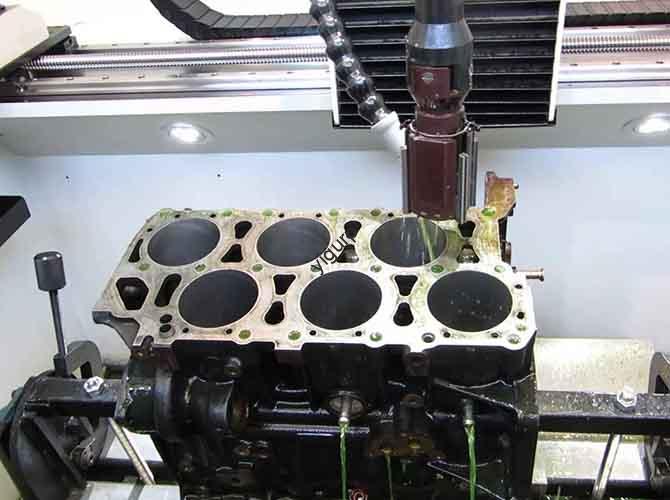

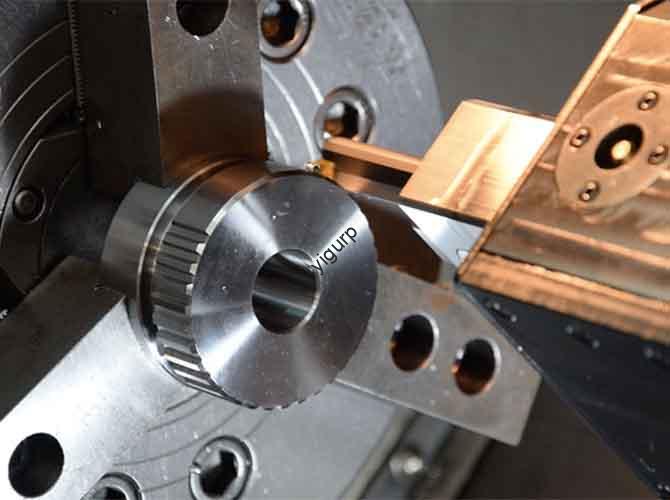

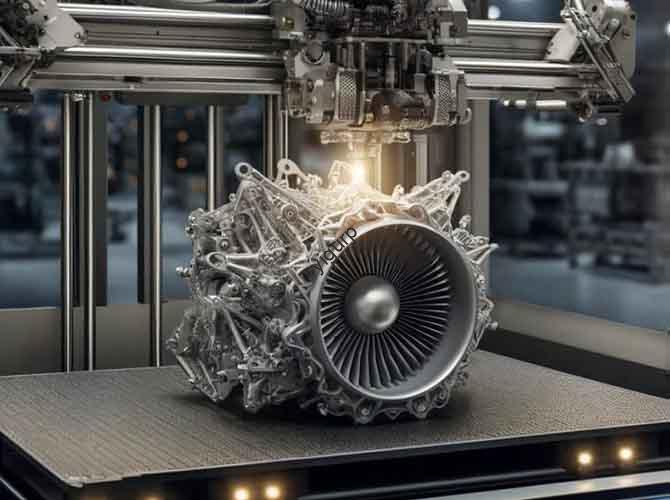

Precision aluminum die casting stands as a cornerstone of advanced manufacturing, merging high-pressure forming, precise mold design, and material optimization to produce complex, high-accuracy aluminum parts. Unlike traditional die casting, it prioritizes dimensional precision (tolerance ±0.1–0.2 mm) and surface quality (Ra 1.6–6.3 μm), making it indispensable for industries like automotive, electronics, and aerospace. This article […]