CNC Machine Service: Guide to Keep Your Equipment Running Perfectly

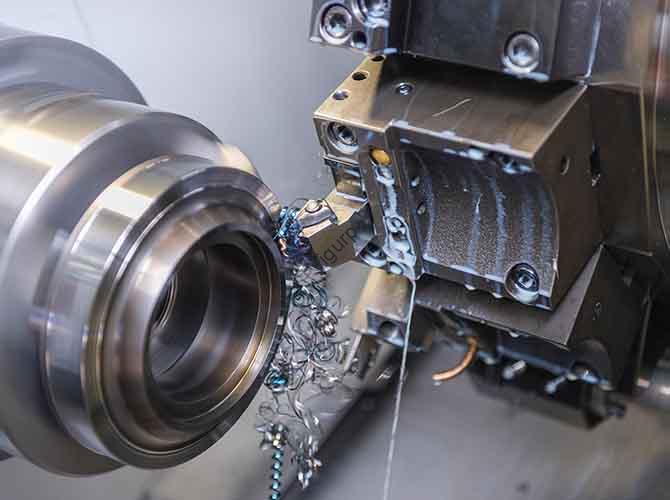

If you’re running a manufacturing shop, you know how crucial your CNC machines are—they’re the backbone of your production. But when they slow down, break down, or lose accuracy, it can throw a wrench in your entire operation. That’s where CNC machine service comes in. This guide isn’t just a list of services; it’s a […]