CNC Machining PPS Prototype Models: Guide for Precision Engineering

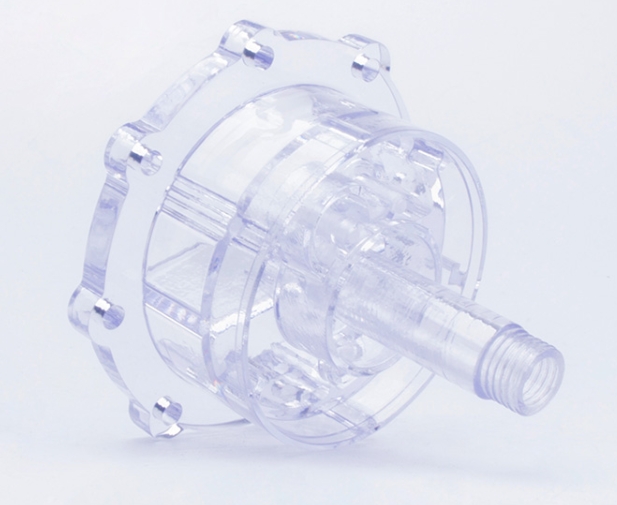

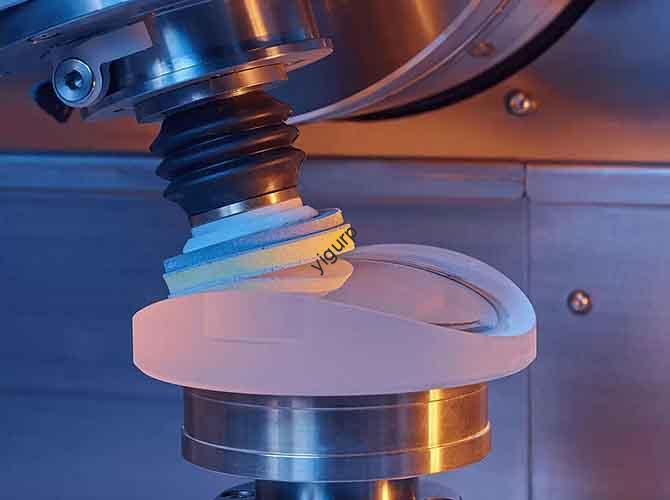

When it comes to creating high-performance prototype parts that can withstand extreme heat and strict dimensional demands, CNC machining PPS prototype models stand out as a top choice for engineers and product developers. Polyphenylene Sulfide (PPS) is a high-performance engineering plastic, and combining it with CNC technology ensures prototypes meet the exacting standards of industries […]