Guide to CNC Machining Prototype Processes: From Selection to Archiving

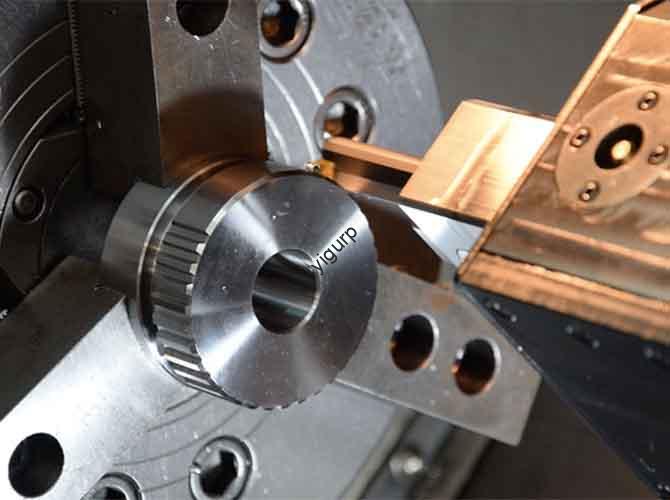

If you’re a procurement professional sourcing prototype parts or a product engineer refining a new design, understanding CNC machining prototype processes is key to ensuring quality, speed, and cost-effectiveness. Unlike traditional machining, CNC (Computer Numerical Control) prototype manufacturing relies on precise computer programming to shape materials—making it ideal for complex or low-volume prototype runs. Below […]