Additive Manufactured Parts: A Complete Guide for Beginners and Professionals

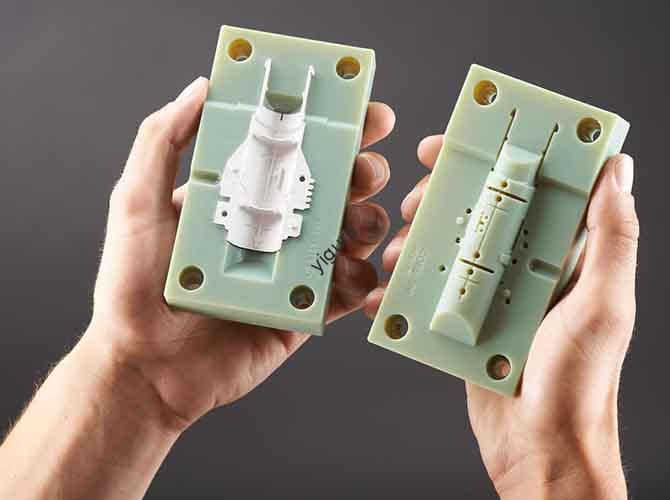

If you’ve ever wondered what additive manufactured parts are and why they’re revolutionizing industries from aerospace to healthcare, you’re in the right place. Simply put, additive manufactured parts are components created through 3D printing technologies, where material is built up layer by layer—unlike traditional “subtractive” methods that cut or drill material away from a solid […]