Large-Scale 3D Printing: Technologies, Advantages, and Future Trends

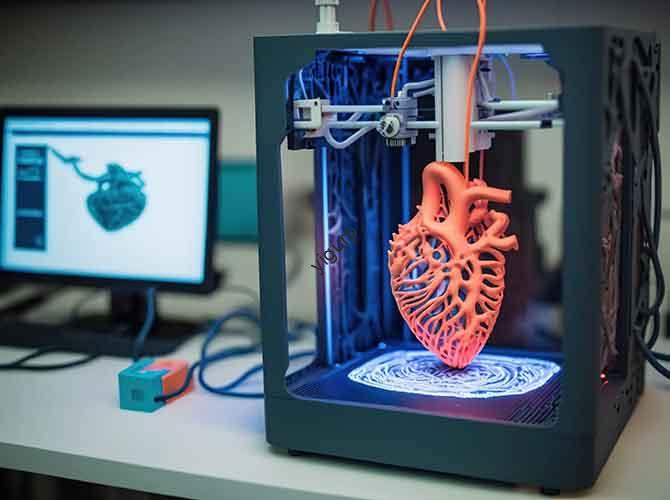

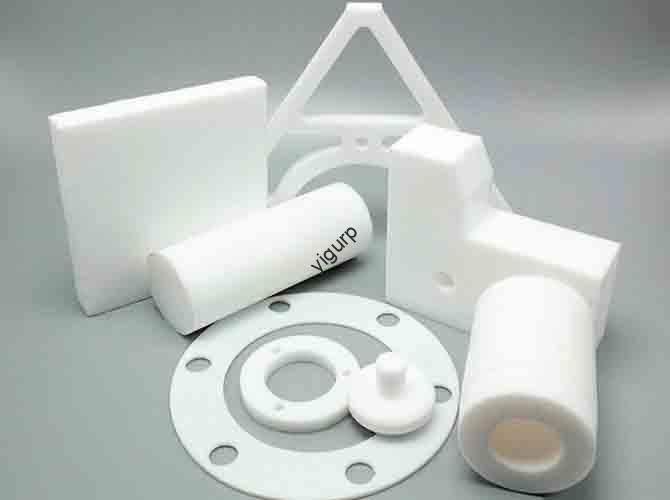

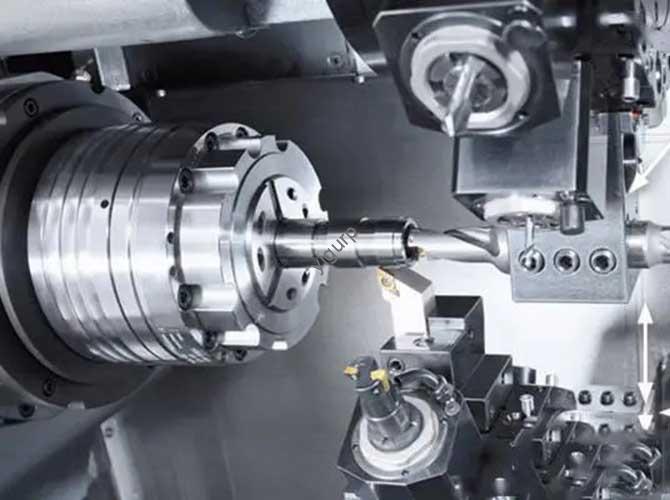

Large-scale 3D printing has redefined modern manufacturing by enabling the production of oversized, complex components—from aerospace parts to entire building structures—with unprecedented efficiency. Unlike traditional small-format 3D printing, this technology addresses the needs of industries requiring full-scale, custom solutions. This article breaks down its core technologies, key benefits, real-world applications, and upcoming innovations to help […]