3D Printing Rigid Resin: A Complete Guide to Applications, Process, and Problem-Solving

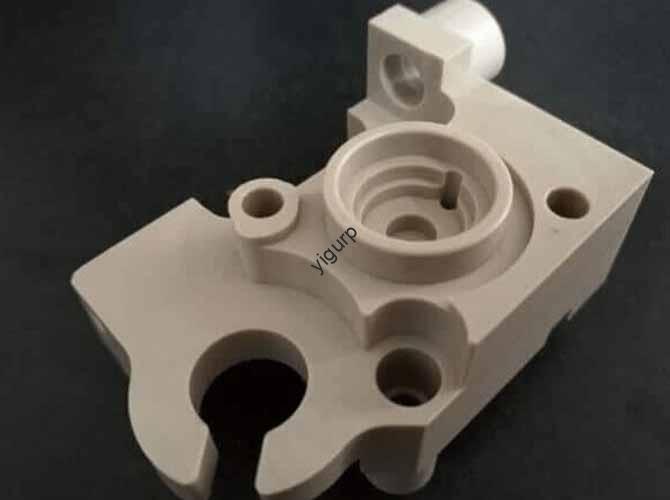

If you’ve ever needed high-strength, precise 3D printed parts—like aerospace components or automotive prototypes—but struggled with flimsy materials or rough surfaces, 3D printing rigid resin is your solution. This light-sensitive material creates robust, detailed parts, but how do you choose the right type? What’s the step-by-step printing process? And how can you fix common issues […]