The Ultimate Guide to CNC Finishing Prototype: From Design to Quality

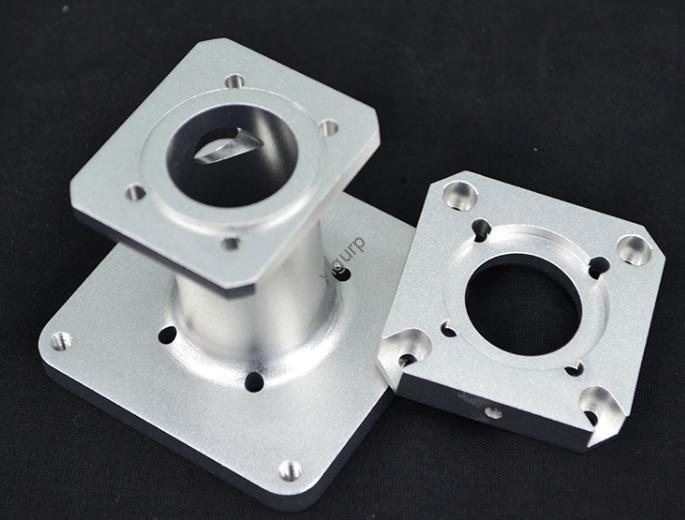

CNC finishing prototype is a high-precision machining process that uses computer numerical control (CNC) technology to refine prototypes or parts, creating near-final products for testing and validation. It plays a critical role in the late stages of product development—helping teams check functionality, appearance, and dimensional accuracy before mass production. This guide covers every key step […]