Simple Mold Production and Processing Process for Low-Cost, Flexible Manufacturing

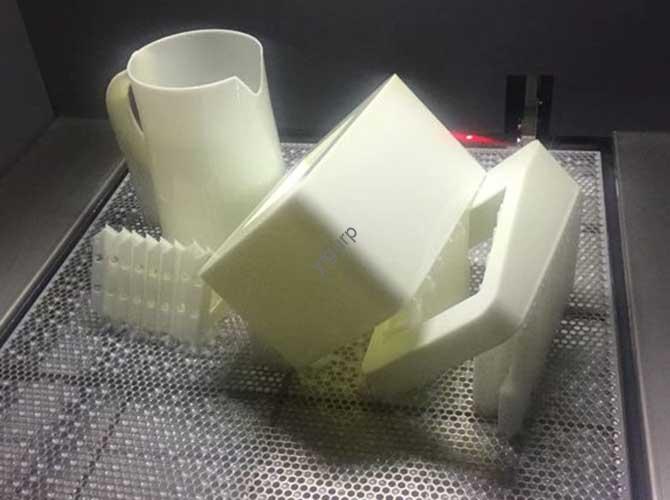

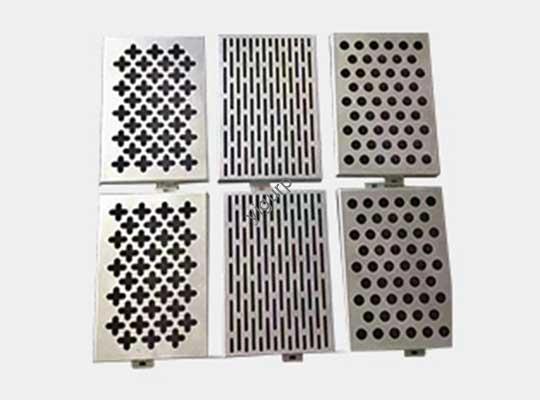

In product development, not every project needs expensive, high-volume tooling. Whether you’re validating a new design, testing a product in the market, or making personalized items, the simple mold production and processing process offers a flexible, budget-friendly solution. It bridges the gap between prototype and full-scale production, making it easy to turn ideas into tangible products—without the […]