Why is CNC laser cutting design a core skill in industry?

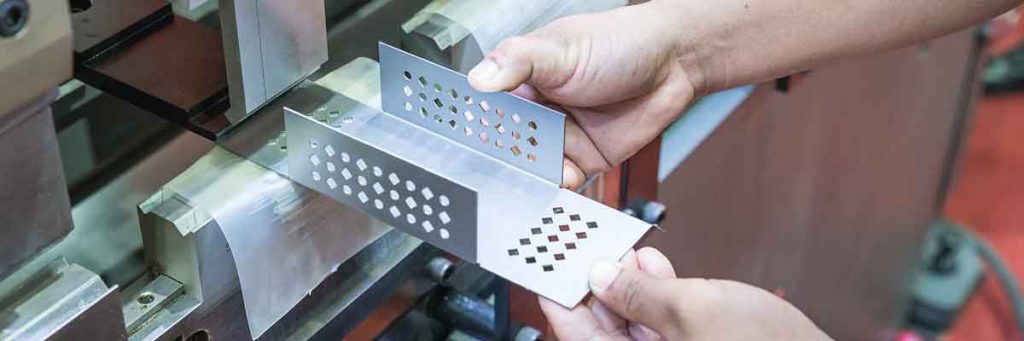

In various fields such as industrial manufacturing, art design, and auto parts processing, CNC laser cutting has become the mainstream processing method with its advantages of high precision and efficiency. However, many users will encounter problems such as “incomplete cutting”, “burrs on the edges”, and “file import errors” in actual operation, and the core reason […]