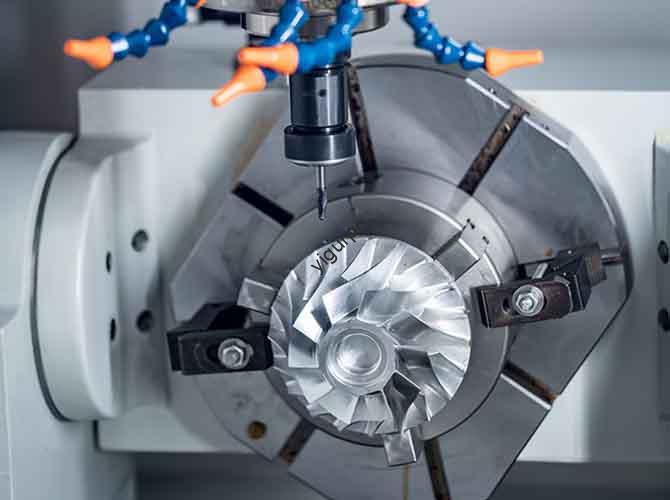

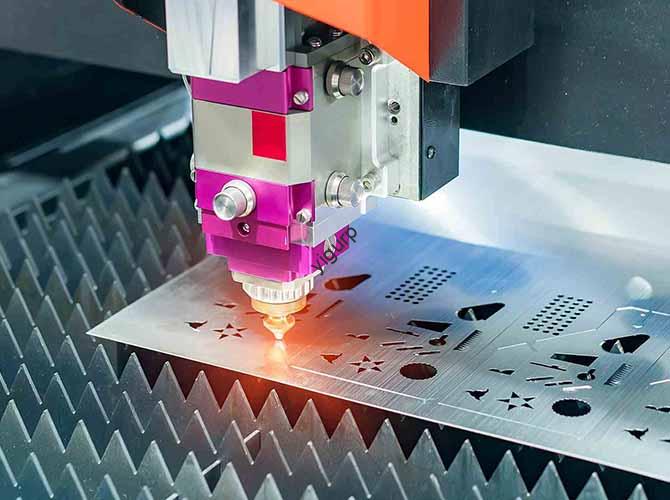

Precision Machining Components: Guide to Design, Manufacturing & Applications

In today’s high-tech manufacturing landscape, precision machining components serve as the backbone of countless industries—from aerospace and medical devices to automotive and electronics. These components, crafted with exceptional accuracy and consistency, ensure the reliability, efficiency, and performance of end products. Whether you’re an engineer selecting components for a new project, a procurement specialist sourcing materials, […]