If you’re in the oil and gas, بناء, or engineering industry, you know how critical it is to pick the right steel for high-pressure, مشاريع المخاطر العالية. هذا هو المكانX65 API pipeline steel comes in—it’s a top choice for demanding applications, thanks to its unbeatable mix of strength, متانة, والتنوع. This guide will walk you through everything you need to know to decide if X65 is the right fit for your next project.

1. Material Properties of X65 API Pipeline Steel

X65’s performance starts with its carefully engineered properties. Let’s break them down into four key categories to make it easy to understand.

التكوين الكيميائي

الالتكوين الكيميائي of X65 API steel is tailored to boost strength, صلابة, and resistance to wear. أدناه هو انهيار نموذجي (per API 5L standards, the global benchmark for pipeline steels):

| عنصر | نطاق المحتوى (بالوزن ٪) | دور رئيسي |

|---|---|---|

| الكربون (ج) | 0.24 الأعلى | Adds strength without making the steel too brittle for forming/welding |

| المنغنيز (MN) | 1.60 الأعلى | Improves toughness and helps with weldability |

| السيليكون (و) | 0.40 الأعلى | Removes oxygen during steelmaking (prevents defects) |

| الفسفور (ص) | 0.030 الأعلى | تسيطر عليها بدقة (low levels avoid brittleness in cold environments) |

| الكبريت (ق) | 0.015 الأعلى | Minimized to prevent cracking during rolling or welding |

| الكروم (كر) | 0.50 الأعلى | يعزز مقاومة التآكل (vital for underground or marine pipelines) |

| الموليبدينوم (شهر) | 0.20 الأعلى | يعزز القوة في درجات حرارة عالية (good for hot oil pipelines) |

| النيكل (في) | 0.30 الأعلى | يحسن صلابة درجات الحرارة المنخفضة (works in freezing regions) |

| الفاناديوم (الخامس) | 0.08 الأعلى | Refines the steel’s grain structure for better overall mechanical performance |

الخصائص الفيزيائية

These traits affect how X65 behaves in real-world conditions—from temperature changes to weight calculations:

- كثافة: 7.85 ز/سم (مثل معظم الفولاذ الهيكلي, so it’s easy to estimate project weight)

- نقطة الانصهار: ~1450–1510°C (compatible with standard steel manufacturing processes)

- الموصلية الحرارية: 44 ث/(م · ك) (spreads heat evenly, reducing stress during welding)

- معامل التمدد الحراري: 13.4 × 10⁻⁶/درجة مئوية (low enough to avoid warping in extreme temperature swings)

- المقاومة الكهربائية: 0.18 × 10⁻⁶ ω · م (لا تستخدم للأجزاء الكهربائية, but useful for safety planning)

الخصائص الميكانيكية

This is where X65 truly stands out—it’s built to handle high pressure and heavy loads. Here are its key mechanical traits:

- قوة الشد: 530-690 ميجا باسكال (can withstand intense pulling forces without breaking)

- قوة العائد: الحد الأدنى 448 MPA (stays strong even when stretched—critical for high-pressure pipelines)

- صلابة: 170-200 HB (يقاوم التآكل من التربة, fluids, or moving parts)

- تأثير المتانة: ≥ 40 J في -40 درجة مئوية (performs reliably in cold climates like Canada or Siberia)

- ليونة: ≥ 20% استطالة (can bend or form into pipes without cracking)

- مقاومة التعب: Excellent for repeated stress (ideal for machine parts or vibrating pipeline components)

- الكسر المتانة: عالي (prevents sudden, catastrophic failure in high-pressure oil/gas lines)

خصائص رئيسية أخرى

- قابلية اللحام الجيدة: Works with common methods like MIG, تيغ, and stick welding—no special equipment needed, توفير الوقت والمال.

- قابلية تشكيل جيدة: Can be hot-rolled into pipes, cold-bent into structural shapes, or forged into custom parts.

- مقاومة التآكل: Holds up well in soil, fresh water, والمواد الكيميائية المعتدل (add a coating for harsh environments like saltwater).

- صلابة: Maintains strength in extreme temperatures—from -40°C (freezing) to 60°C (hot deserts).

2. Applications of X65 API Pipeline Steel

X65 isn’t just for pipelines—it’s versatile enough to solve problems across multiple industries. Here’s how it’s used in real projects:

صناعة خطوط الأنابيب

ال #1 use forX65 API pipeline steel يكونoil and gas pipelines. Its high yield strength and corrosion resistance make it perfect for transporting high-pressure crude oil, الغاز الطبيعي, and refined fuels over long distances.

دراسة حالة: A major energy company used X65 steel for a 1,500 km natural gas pipeline in Western Australia. The pipeline had to handle 10 MPa of pressure and survive 50°C summer heat. بعد 8 سنين, inspections showed zero corrosion (thanks to a fusion-bonded epoxy coating) and no signs of stress—proving X65’s reliability in harsh conditions.

صناعة البناء

في البناء, X65 is used for heavy-duty structural needs:

- مكونات الصلب الهيكلي (supports for industrial buildings)

- عوارض و الأعمدة (for bridges and high-rise towers)

- بناء إطارات (for warehouses and power plants)

Why choose X65? It’s stronger than mild carbon steel but more affordable than higher-grade HSLA steels. على سبيل المثال, a highway bridge in Texas used X65 beams to support heavy truck traffic (حتى 80,000 lbs per vehicle). بعد 5 سنين, the beams showed no bending or wear—saving the state money on repairs.

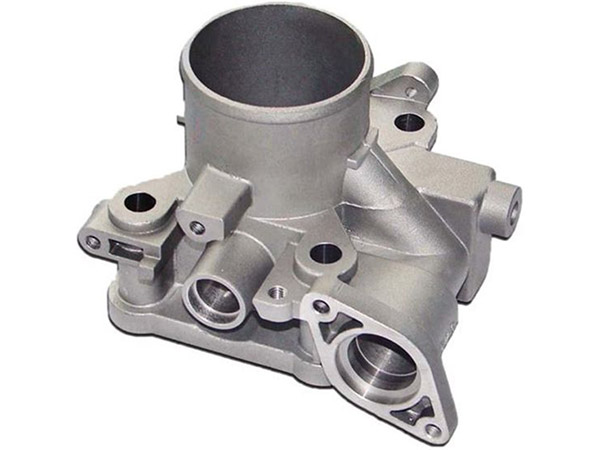

الهندسة الميكانيكية

Mechanical engineers rely on X65 for parts that need strength and durability:

- التروس (إنه صلابة و مقاومة التعب prevent wear from constant movement)

- مهاوي (handles rotational stress in pumps and motors)

- أجزاء الآلة (durable for factory equipment like conveyors)

A manufacturing plant switched to X65 for its gear systems. The X65 gears lasted 4x longer than the mild steel gears they replaced—cutting downtime by 30%.

صناعة البحرية

X65 works well in saltwater and offshore environments:

- هياكل السفينة (hulls and deck supports)

- المنصات الخارجية (legs and braces for oil rigs)

دراسة حالة: An offshore oil platform in the Gulf of Mexico used X65 steel for its support legs. The steel was coated with zinc to boost corrosion resistance. بعد 12 سنين, the legs showed only minor rust—far less than the 5-year lifespan of the previous carbon steel legs.

الآلات الزراعية

Farmers use X65 for heavy-duty equipment that faces rough conditions:

- Tractor parts (frames and engine components)

- المحاريث و هاروز (resist wear from rocks and hard soil)

A farm equipment maker tested X65 plows against standard steel plows. The X65 plows lasted 2 full growing seasons (مقابل. 1 للصلب القياسي) and required fewer sharpenings—saving farmers time and money.

3. Manufacturing Techniques for X65 API Pipeline Steel

Making X65 steel requires precise steps to ensure its properties are consistent. Here’s a step-by-step look at the process:

عمليات صناعة الصلب

Two main methods produce X65 API steel, depending on volume and raw materials:

- فرن الأكسجين الأساسي (bof): The most common method for large-scale production. It uses molten iron (من فرن الصهر) and blows oxygen into it to remove impurities. عناصر السبائك (like Mn and Mo) are added to reach X65’s chemical specs. Fast and cost-effective for mass-produced pipes.

- فرن القوس الكهربائي (EAF): Uses electricity to melt scrap steel. Great for smaller batches or custom orders (على سبيل المثال, specialized X65 parts for machinery). More flexible but slightly slower than BOF.

المعالجة الحرارية

Heat treatment fine-tunes X65’s mechanical properties to meet API 5L standards:

- التطبيع: Heats the steel to 860–960°C, then cools it in air. Improves ductility and makes the steel’s structure uniform (good for parts that need bending).

- تبريد وتهدئة: Heats to 900–950°C, quenches (يبرد بسرعة) في الماء أو الزيت, then tempers (reheats) to 550–650°C. This process boosts قوة العائد و صلابة—critical for high-pressure pipelines.

- الصلب: درجات الحرارة إلى 800-850 درجة مئوية, cools slowly in a furnace. Reduces stress from forming (used for precision parts like gears).

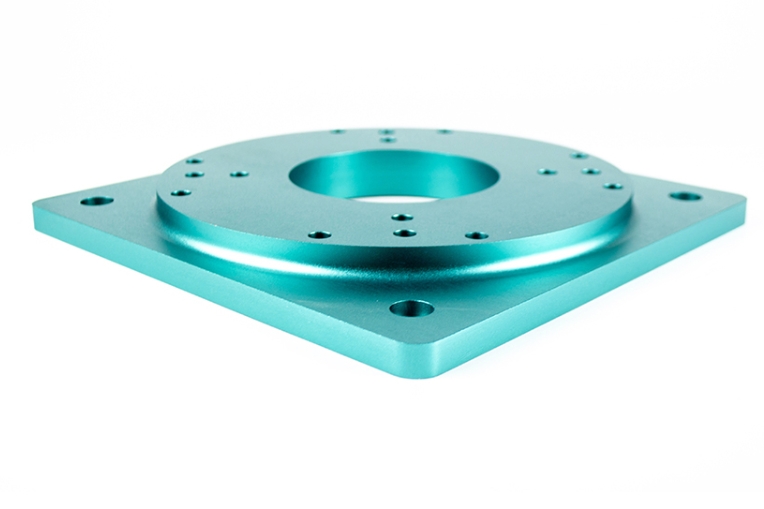

تشكيل العمليات

X65 is shaped into final products using these methods:

- المتداول الساخن: Heats the steel to 1100–1200°C, then rolls it through machines to make pipes, عوارض, أو أوراق. Fast and ideal for large-volume pipeline production.

- المتداول البارد: Rolls the steel at room temperature. Creates smoother surfaces and tighter dimensions (used for precision parts like shafts).

- تزوير: Hammers or presses hot steel into complex shapes (على سبيل المثال, أجزاء الآلة المخصصة). Improves strength by aligning the steel’s grain structure.

- البثق: Pushes heated steel through a die to make tubes or hollow parts (used for small-diameter pipelines).

- ختم: Uses presses to cut or bend flat steel into parts like brackets (common in construction).

المعالجة السطحية

To boost corrosion resistance and lifespan, X65 gets these surface treatments:

- الجلفنة: Dips the steel in molten zinc. Creates a protective layer that prevents rust (يدوم 20+ سنوات في الهواء الطلق).

- تلوين: Applies epoxy or polyurethane paint. Ideal for above-ground pipelines or structural parts.

- إطلاق النار: Blasts the steel with tiny metal balls to remove rust, حجم, or dirt. Prepares the surface for coating.

- طلاء: Uses fusion-bonded epoxy (FBE) or 3-layer polyethylene (3LPE) for pipelines. These coatings resist chemicals, soil, and saltwater—extending the steel’s life by 30+ سنين.

4. X65 API Pipeline Steel vs. مواد أخرى

How does X65 compare to other common materials? Let’s break it down with clear comparisons to help you choose.

X65 vs. فولاذ الكربون (على سبيل المثال, A36)

| عامل | X65 API Pipeline Steel | الصلب الكربون المعتدل (A36) |

|---|---|---|

| قوة العائد | 448 MPa min | 250 MPa min |

| صلابة | ممتاز (-40درجة مئوية) | جيد (0°C only) |

| قابلية اللحام | جيد | جيد جدًا |

| الأداء التكلفة | Better for high-pressure projects | Cheaper for light use (على سبيل المثال, سياج) |

| الأفضل ل | Oil/gas pipelines, الجسور الثقيلة | المباني الصغيرة, الأجزاء غير الحرجة |

X65 vs. عالي القوة منخفضة (HSLA) فولاذ (على سبيل المثال, X80)

- التكوين الكيميائي: HSLA فولاذ (like X80) have more alloying elements (على سبيل المثال, نيوبيوم, التيتانيوم) than X65, making them stronger.

- ملكيات: X80 has a higher yield strength (551 MPa min) but is less ductile than X65. X65 is easier to form and weld.

- التطبيقات: X80 is for ultra-high-pressure pipelines; X65 is better for most standard high-pressure projects (more cost-effective).

X65 vs. فولاذ مقاوم للصدأ (على سبيل المثال, 304)

| عامل | X65 API Pipeline Steel | الفولاذ المقاوم للصدأ (304) |

|---|---|---|

| مقاومة التآكل | جيد (مع الطلاء) | ممتاز (لا طلاء) |

| قوة العائد | 448 MPa min | 205 MPa min |

| يكلف | أدنى ($1.00–$1.50/lb) | أعلى ($2.80–$3.80/lb) |

| الأفضل ل | High-pressure pipelines | معالجة الأغذية, المعدات الطبية |

X65 vs. سبائك الألومنيوم (على سبيل المثال, 6061)

- وزن: الألومنيوم هو 1/3 the weight of X65 (great for aircraft), but X65 is 2x stronger.

- مقاومة التآكل: Aluminum resists rust better, but X65 (مع الطلاء) handles soil and oil better.

- يكلف: X65 is cheaper than high-grade aluminum (saves money on large projects like pipelines).

- تصنيع: Aluminum is easier to cut, but X65 is better for high-temperature or high-pressure uses.

5. Yigu Technology’s Perspective on X65 API Pipeline Steel

في Yigu Technology, we’ve helped hundreds of clients useX65 API pipeline steel for critical projects—from oil pipelines to bridge structures. We see X65 as a “workhorse” material: إنه يوازن بين القوة, يكلف, and versatility better than most steels. For oil and gas clients, X65’s 448 MPa yield strength and cold-temperature toughness solve the biggest pain points (الضغط العالي, harsh weather). لعملاء البناء, it’s a cost-effective upgrade from mild steel. We also optimize X65’s manufacturing—using BOF for large pipeline orders and EAF for custom parts—to cut lead times. إجمالي, X65 is our top recommendation for projects that need reliability without overspending.

FAQ About X65 API Pipeline Steel

1. Can X65 API steel be used for offshore pipelines?

نعم! X65 works great for offshore pipelines when paired with a corrosion-resistant coating (like 3LPE). إنهصلابة handles wave stress, and the coating prevents saltwater rust. We’ve supplied X65 for offshore projects in the South China Sea that have lasted 10+ سنوات مع عدم وجود مشاكل.

2. Is X65 API steel harder to weld than mild steel?

No—X65 hasقابلية اللحام الجيدة and works with the same equipment as mild steel (أنا, تيغ, يلزق). The only tip: keep carbon levels low (per API 5L specs) to avoid brittleness in the weld. Most fabricators don’t need special training to weld X65.

3. How long does X65 API steel last in underground pipelines?

With a proper coating (like FBE), X65 can last 30–50 years underground. بدون طلاء, it lasts 15–20 years (depending on soil moisture). We recommend regular inspections (اختبار الموجات فوق الصوتية) كل 5 years to extend its life even further.