In today’s industrial landscape, finding reliable custom plastic products manufacturers is crucial for businesses across diverse sectors. These manufacturers specialize in creating tailored plastic components that meet unique specifications, from intricate geometries to specific performance requirements. This guide explores the world of custom plastic manufacturing, highlighting key processes, مواد, المزايا, and how leading manufacturers like Xometry and Central Plastics deliver exceptional results.

Understanding Custom Plastic Products Manufacturing

Custom plastic products manufacturing is a specialized field focused on producing plastic components designed to exact client specifications. Unlike off-the-shelf plastic parts, custom solutions offer businesses the flexibility to create components that perfectly fit their unique applications, rather than adapting their designs to available standard parts.

Leading custom plastic products manufacturers leverage advanced technologies and decades of expertise to transform concepts into tangible products. The process typically involves several key stages: initial design consultation, اختيار المواد, prototyping, خلق العفن, production, and rigorous quality inspection. This comprehensive approach ensures that the final products meet all functional, aesthetic, ومتطلبات الأداء.

Core Manufacturing Processes Offered by Top Manufacturers

Reputable custom plastic products manufacturers offer a diverse range of production processes to accommodate different project needs. Here are the most common methods:

Plastic Injection Molding

Injection molding stands as a cornerstone process for many custom plastic products manufacturers. This method involves injecting molten plastic material into a precision-engineered mold cavity. Once cooled and solidified, the part is removed from the mold, resulting in consistent, مكونات عالية الجودة. Key advantages include:

- High production speed, ideal for large-volume orders

- Exceptional accuracy, with tolerances as tight as 0.005 بوصات

- Versatility in design, supporting complex geometries

- Cost-effectiveness for mass production due to economies of scale

Blow Molding

Blow molding is specialized for creating hollow plastic products. The process involves inflating a heated plastic parison (tube) inside a mold, where it takes the shape of the cavity. This method is particularly cost-effective for manufacturing:

- Plastic bottles and containers

- Fuel tanks and fluid reservoirs

- Hollow structural components

- Lightweight packaging solutions

Manufacturers often recommend blow molding for large-volume production of hollow items, as it offers excellent cost efficiency at scale.

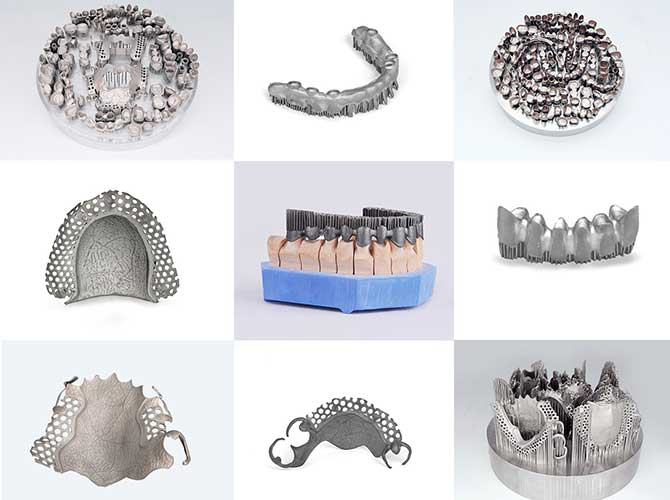

Precision Molding

Taking injection molding to the next level, precision molding caters to applications requiring extreme accuracy and consistency. This process is essential for industries where even minor dimensional variations can affect performance, such as aerospace and medical device manufacturing. Precision molding delivers:

- Tighter tolerances than standard injection molding

- Superior surface finishes

- Consistent part quality across production runs

- Enhanced material properties through specialized processing

Plastic Extrusion

Extrusion is used to create continuous plastic profiles with consistent cross-sections. The process involves forcing molten plastic through a die to produce long, uniform shapes. Common applications include:

- Pipes and tubing

- Seals and gaskets

- Trim and edging components

- Custom profiles for construction and industrial use

Plastic Machining

For highly intricate or specialized components, plastic machining offers a precise solution. This subtractive manufacturing process uses cutting tools to remove material from a plastic workpiece, creating complex shapes and exact dimensions. Machining is ideal for:

- Prototypes and low-volume production

- Components with complex geometries

- Parts requiring exceptional surface finishes

- Custom modifications to standard parts

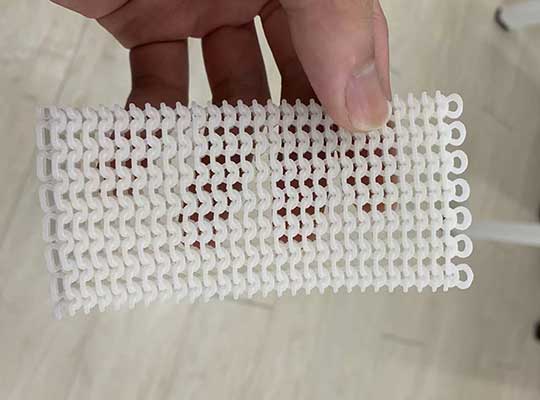

Plastic Prototyping Services

Leading custom plastic products manufacturers understand the importance of prototyping in product development. Prototyping services, including 3D printing and urethane casting, allow clients to:

- Test and evaluate designs before full-scale production

- Identify potential design issues early in the process

- Make necessary adjustments without expensive mold modifications

- Validate functionality and performance

اختيار المواد: Choosing the Right Plastic for Your Project

Selecting appropriate materials is a critical step in custom plastic manufacturing. Top custom plastic products manufacturers offer a wide range of thermoplastic and thermosetting materials, لكل منها خصائص فريدة:

| مادة | الخصائص الرئيسية | التطبيقات المشتركة |

| HDPE (High-Density Polyethylene) | Excellent strength-to-weight ratio, مقاومة التأثير, high melting point | Milk jugs, cutting boards, plastic pipes, 3D طباعة خيوط |

| البولي بروبيلين (ص) | Chemical resistance, آمن الطعام, high-temperature tolerance, cost-effective | Packaging, مصدات السيارات, medical syringes, disposable cutlery |

| PVC (Polyvinyl Chloride) | Chemical resistance, القدرة على تحمل التكاليف, العزل الكهربائي, fire resistance | Plumbing pipes, electrical cables, construction materials, insulation |

| القيمة المطلقة (acrylonitrile butadiene styrene) | Impact resistance, قوة, متانة, smooth surface finish | Automotive parts, electronic housings, ألعاب, kitchen appliances |

| أسيتال (بوم) | Low friction, صلابة عالية, excellent dimensional stability | التروس, المحامل, البطانات, precision engineering components |

| نايلون 6 & 66 | Exceptional tensile strength, مقاومة الحرارة, abrasion resistance | مكونات السيارات, textiles, industrial parts |

| PBT (Polybutylene Terephthalate) | Electrical insulation, مقاومة الحرارة, المقاومة الكيميائية, moisture resistance | الموصلات الكهربائية, مكونات السيارات, أجزاء دقيقة |

| البولي | Outstanding impact resistance, الوضوح البصري, versatility | Eyewear lenses, الأجهزة الطبية, electronic housings, مكونات السيارات |

Custom plastic products manufacturers work closely with clients to select materials that balance performance requirements, cost considerations, and manufacturing feasibility.

Advantages of Partnering with Professional Custom Plastic Products Manufacturers

Choosing to work with experienced custom plastic products manufacturers offers numerous benefits for businesses:

Bespoke Solutions

Custom plastic manufacturing allows for components tailored precisely to your design requirements, eliminating the need to adapt designs to fit standard off-the-shelf parts. This flexibility enables innovation and optimization of product performance.

Cost Effectiveness

While initial setup costs may exist, custom plastic manufacturing becomes highly cost-effective over time, especially for large production runs. Automation reduces labor costs, and processes like injection molding benefit significantly from economies of scale.

Reduced Assembly Complexity

Custom-designed parts often integrate multiple functions, reducing the total number of components needed in assemblies. This simplification saves time during production and reduces the risk of supply chain disruptions from relying on multiple off-the-shelf parts.

Enhanced Wear Resistance

Manufacturers can engineer custom plastic parts with specific wear-resistant properties, extending component lifespans and reducing replacement frequencies. This enhances overall product reliability and lowers long-term maintenance costs.

High Accuracy and Repeatability

Advanced manufacturing processes deliver exceptional precision, with consistent quality across entire production runs. This reliability is crucial for applications where dimensional accuracy directly impacts performance and safety.

Versatility in Design

Custom plastic manufacturing supports a wide range of shapes, colors, finishes, and material combinations. This versatility enables the production of complex, specialized components that meet unique application requirements.

Improved Efficiency

The process requires minimal finishing work compared to other manufacturing methods, reducing production time. بالإضافة إلى ذلك, many manufacturers implement recycling programs for scrap materials, improving material efficiency and reducing waste.

Potential Challenges in Custom Plastic Manufacturing

While the benefits are significant, it’s important to be aware of potential challenges when working with custom plastic products manufacturers:

Initial Setup Costs

The creation of custom molds represents a substantial upfront investment. Tooling expenses can be particularly significant for complex designs or large parts, requiring careful budgeting in project planning.

أوقات الرصاص أطول

Achieving precision in custom plastic parts often requires extensive prototyping and tooling development. These steps can extend production timelines compared to using standard components.

Modification Difficulties

Once molds are created, making changes can be expensive and time-consuming, especially with durable steel molds. This underscores the importance of thorough design validation during the prototyping phase.

Design Limitations

While custom plastic manufacturing offers great flexibility, certain design complexities may present manufacturing challenges. Working closely with manufacturers during the design phase helps identify and address these limitations early.

Industries Served by Custom Plastic Products Manufacturers

Leading manufacturers provide solutions for a wide range of industries, each with unique requirements:

صناعة السيارات

Custom plastic parts play a vital role in modern vehicles, including interior components, exterior trims, dashboard elements, and engine components. Manufacturers deliver parts that balance durability, weight reduction, and cost efficiency.

صناعة الطيران

The aerospace sector demands components that meet stringent performance and safety standards. Custom plastic parts find applications in aircraft interiors, avionics, and even structural elements, where lightweight properties and reliability are critical.

الصناعة الطبية

Medical device manufacturers rely on custom plastic components for devices, laboratory equipment, and diagnostic tools. These parts must meet strict biocompatibility, العقم, and precision requirements.

إلكترونيات المستهلك

From smartphones to home appliances, custom plastic parts provide structural integrity, aesthetic appeal, والوظائف. Manufacturers produce housings, connectors, and internal components that meet the industry’s demands for miniaturization and performance.

Additional Sectors

Beyond these core industries, custom plastic products manufacturers serve telecommunications, industrial equipment, robotics, defense, التغليف, and toy & education sectors, providing specialized components tailored to each field’s unique needs.

Quality Assurance in Custom Plastic Manufacturing

Reputable custom plastic products manufacturers prioritize quality through rigorous processes and certifications:

- ISO Certifications: Leading manufacturers maintain ISO 9001:2015 (general quality management), ISO 13485 (medical device quality management), and AS9100D (aerospace quality management) certifications.

- Comprehensive Testing: From material inspection to final product testing, manufacturers implement strict quality checks at every production stage.

- Continuous Improvement: Quality management systems emphasize ongoing process optimization and feedback integration.

- Facility Standards: State-of-the-art facilities with advanced equipment ensure consistent production quality.

This commitment to quality ensures that custom plastic parts meet or exceed industry standards and client expectations across all sectors.

Why Choose Established Custom Plastic Products Manufacturers?

Partnering with experienced manufacturers offers distinct advantages:

- Access to a comprehensive range of manufacturing processes under one roof

- Expert guidance on material selection, design optimization, and cost reduction

- Established quality management systems ensuring consistent results

- Efficient production timelines through optimized processes

- Scalability from prototyping to high-volume production

- Industry-specific expertise addressing unique sector requirements

Whether you need a single prototype or millions of production parts, established manufacturers have the capabilities and experience to deliver successful outcomes.

منظور Yigu Technology

Yigu Technology recognizes that top custom plastic products manufacturers are vital for industrial innovation. Their blend of advanced processes, material expertise, and quality focus delivers tailored solutions that drive product performance. By bridging design concepts with manufacturing reality, these partners help businesses turn ideas into high-quality, cost-effective plastic components that meet diverse industry demands.

الأسئلة المتداولة (التعليمات)

What factors should I consider when choosing custom plastic products manufacturers?

Key considerations include manufacturing capabilities matching your project needs, relevant industry experience, quality certifications, material selection options, production lead times, and cost structure. Requesting samples and checking client references can also help evaluate capabilities.

How long does custom plastic part production typically take?

Timelines vary based on complexity, production volume, and processes involved. Prototyping can take 1-4 أسابيع, while mold creation may require 4-8 أسابيع. Once tooling is complete, production runs can deliver initial parts within days to weeks, with larger volumes taking longer based on quantity.

Can custom plastic manufacturers help with design optimization?

نعم, most experienced manufacturers offer design for manufacturability (DFM) services. Their engineers can suggest modifications to improve production efficiency, تقليل التكاليف, enhance performance, and ensure design feasibility, often saving time and money in the long run.