In the competitive world of furniture manufacturing, finding a reliable plastic chair mould that delivers consistent quality, efficient production, and long service life is a significant challenge. Manufacturers often struggle with issues like uneven wall thickness, poor parting lines, short mould lifespan, and excessive cycle times that increase production costs. Many mould suppliers claim to offer high-quality solutions, but few can truly deliver on these promises. This guide will help you navigate the complexities of selecting and working with plastic chair moulds, addressing these pain points with expert insights and practical advice.

Understanding Plastic Chair Mould Materials and Composition

The foundation of a high-quality plastic chair mould lies in its materials and composition, which directly impact durability, أداء, and part quality.

Key Materials in Plastic Chair Mould Construction

- Mould Steels: Premium moulds use high-grade steels like DIN 1.2316, DIN 1.2738, DIN 1.2344, M300, 718, and P20. These steels offer excellent wear resistance and heat tolerance, essential for maintaining precision over thousands of cycles.

- Cavity and Core Hardness: The optimal hardness range for cavity and core components is 32-50 HRC, with wear parts requiring even higher hardness (55-60 HRC) for extended durability.

- Plastic Resins Compatibility: Moulds must be designed to work with various plastics including PVC, ص, PE, القيمة المطلقة, PS, بوم, and PPH. For lightweight yet strong chairs, low MFI PP (Melt Flow Index 4-6) is preferred despite its challenging flow characteristics.

- Surface Treatments: Hard chrome plating is recommended for moulds used with recycled materials to prevent premature wear and rust, ensuring long-lasting finishing.

The choice of materials directly affects the mould’s lifespan, which should range from 500,000 ل 5,000,000 shots with proper maintenance.

Design and Aesthetics: Critical Elements of Plastic Chair Moulds

Superior design is what distinguishes an average plastic chair mould from an exceptional one, impacting both functionality and visual appeal.

Essential Design Features for Optimal Performance

- Ergonomic Considerations: Mould designs must incorporate ergonomic principles to ensure comfortable seating while maintaining structural integrity.

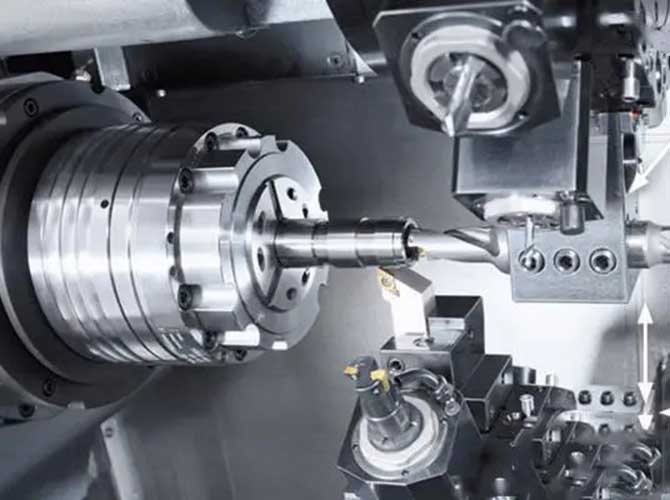

- Parting Line Excellence: Achieving smooth parting lines without sharp edges requires precision in design and manufacturing. This involves three stages of CNC milling: rough milling, stress-relieved half-precise milling (leaving 0.3mm), and final precise milling with cutting depths no greater than 0.08mm.

- Wall Thickness Uniformity: Proper 3D design and precise CNC machining prevent uneven wall thickness, which can cause injection imbalances, extended cooling times, and shrinkage marks.

- Stackability Engineering: Designing for stackability requires careful consideration of chair geometry and potential moulding deformation to ensure stable stacking without damage.

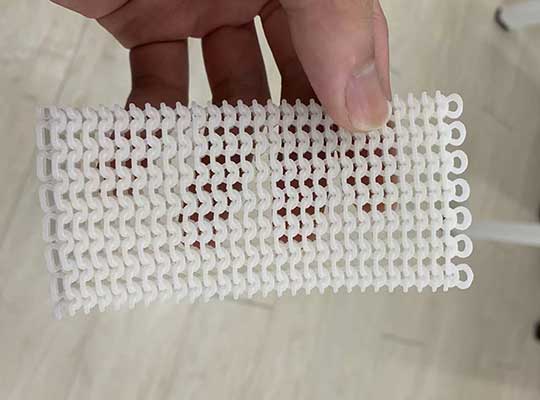

- Specialized Features: Innovative designs include interchangeable chair back inserts for cost-effective customization and gas-assisted molding for complex structures.

These design elements collectively contribute to chairs with smooth surfaces, proper strength, and appealing aesthetics that meet market demands.

Manufacturing Process: Crafting Precision Plastic Chair Moulds

The manufacturing process of a plastic chair mould is a complex sequence requiring precision, expertise, and advanced technology.

Step-by-Step Mould Production Process

- Design and Analysis: Using software like Pro/Engineer, و, و Moldflow analysis for plastic flow and deformation simulation to optimize the design.

- Material Selection and Preparation: Choosing appropriate steels and conducting metallurgical analysis to ensure no segregation or scars in core materials.

- تصنيع CNC: Multi-stage milling operations with strict cooling requirements to prevent steel deformation during processing.

- Heat Treatment: Achieving precise core hardness (عادة 46-50 HRC) with uniform distribution (variation less than 1 HRC across 9 measurement points).

- Electrode Processing: Fine and rough electrode machining with precise benchmarks and post-processing inspection.

- Finishing Operations: Including EDM processing with controlled 火花间隙 (0.03-0.05مم), polishing runner surfaces to ▽6 or ▽7 finish, and ensuring verticality within 0.02mm.

- Assembly and Quality Inspection: Comprehensive cleaning, anti-rust treatment, and inspection of all components before assembly.

- Tryout and Validation: Testing with 100-150 cycles to ensure defect-free production before final approval.

This rigorous process typically takes 60 working days for delivery, with quality moulds achieving cycle times of 35-50 ثوان for chairs weighing 1700-2400g when using proper cooling (8-12°C water temperature) and machines with accumulators.

Applications and Uses: Versatile Plastic Chair Mould Solutions

Plastic chair moulds cater to a wide range of applications, each with specific design requirements.

Specialized Mould Types for Various Applications

- Arm Chair Moulds and Armless Chair Moulds: Designed for different seating preferences in both residential and commercial settings.

- Dinner Chair Moulds: Optimized for restaurant and dining room use with focus on comfort and stackability.

- Children Chair Moulds: Prioritizing safety features, smaller dimensions, and durable construction.

- Gas-Assisted Chair Moulds: Utilizing advanced technology for complex designs with reduced weight.

- Plastic Rattan Chair Moulds: Creating aesthetically pleasing designs that mimic natural rattan.

- Foldable Chair Moulds: Incorporating hinges and locking mechanisms for space-saving functionality.

- Bus Chair Moulds and Beach Chair Moulds: Specialized designs for transportation and outdoor environments respectively.

| طلب | Key Mould Requirements | Typical Materials |

| Indoor Seating | Ergonomic design, smooth finish | ص, القيمة المطلقة |

| Outdoor Furniture | Weather resistance features | UV-stabilized PP, PE |

| Commercial Use | High durability, stackability | Reinforced PP |

| Medical Facilities | Easy-clean surfaces, المقاومة الكيميائية | PVC, ص |

| Industrial Settings | Heavy-duty construction | High-impact PP |

ضبط الجودة: Ensuring Excellence in Plastic Chair Moulds

Maintaining strict quality control throughout the mould manufacturing process is essential for producing reliable, high-performance plastic chair moulds.

Critical Quality Assurance Measures

- دقة الأبعاد: Using precision tools to maintain tolerances within ±0.01mm for critical components.

- Steel Hardness Verification: Ensuring cavity and core hardness meets specified requirements through multiple measurement points.

- Cooling System Validation: Checking that in-core baffle cooling و cavity plate chain drilling type cooling systems function properly for efficient heat dissipation.

- Venting System Inspection: Verifying adequate air venting in complex areas like backrests to prevent air traps during injection.

- Parting Line Inspection: Ensuring smooth transitions without sharp edges that could cause injury or product defects.

- اختبار وظيفي: Evaluating core pulling systems (motor, oil cylinder, stripping plate) and other moving components for reliable operation.

- Certification Compliance: Adhering to quality standards with proper documentation and potentially ISO certifications.

These measures help guarantee that the mould will produce chairs with consistent wall thickness, proper strength, and excellent surface finish throughout its lifespan.

Maintenance and Durability: Maximizing Your Mould Investment

Proper maintenance is key to extending the life of your plastic chair mould and ensuring consistent production quality.

Essential Maintenance Practices

- تنظيف منتظم: Removing residual plastic and debris to prevent buildup that can affect part quality.

- تشحيم: Proper lubrication of moving components like core pulling systems and ejector pins.

- Rust Prevention: Maintaining anti-rust treatments, especially in high-humidity environments.

- Periodic Inspection: Checking for signs of wear, particularly in high-stress areas and parting lines.

- Polishing Maintenance: Re-polishing surfaces as needed, especially for moulds not using hard chrome plating.

- Cooling System Maintenance: Ensuring unobstructed water flow and proper temperature control.

- Storage Practices: Using appropriate storage methods to prevent damage when moulds are not in use.

For moulds used with recycled materials, more frequent maintenance is required unless they feature hard chrome plating, which significantly reduces wear from contaminants.

Yigu Technology’s Perspective on Plastic Chair Mould Development

كمورد نماذج أولية رائدة, Yigu Technology understands that successful plastic chair mould projects begin with accurate prototypes. Our rapid prototyping services help validate chair designs before mould production, identifying potential issues early. This collaboration between prototyping and mould manufacturing reduces development time, minimizes costly mould modifications, and ensures the final product meets both design intent and performance requirements, creating a more efficient path from concept to production.

التعليمات

- What factors determine the cycle time of a plastic chair mould?

Cycle time (عادة 35-50 seconds for standard chairs) is influenced by cooling water temperature (8-12°C optimal), chair weight (1700-2400g), cooling channel design, and whether the injection machine uses accumulators for faster plastic melt and injection.

- How can I ensure my plastic chair mould produces chairs with even wall thickness?

Even wall thickness requires proper 3D design, precise CNC milling (avoiding excessive cutting depths), adequate polishing of cavities/cores, and Moldflow analysis during the design phase to optimize material flow.

- What is the typical lifespan of a high-quality plastic chair mould?

With proper maintenance, high-quality plastic chair moulds made from premium steels (like DIN 1.2344) can achieve a lifespan of 500,000 ل 5,000,000 shots, depending on materials processed and maintenance practices.