إذا كنت مطور منتج, مهندس, or designer gearing up for CNC prototype machining, you know precision is non-negotiable. Even small mistakes in the process can ruin a prototype, delay development, وزيادة التكاليف. The good news? By following critical best practices, you can avoid these pitfalls. في هذا الدليل, سنقوم بتفكيك must-know considerations for CNC prototype machining—from material selection to quality control—to help you get reliable, accurate prototypes every time.

1. اختيار المواد: Match Materials to Prototype Needs

The first step in successful CNC prototype machining is choosing the right material. Your selection should align with the prototype’s purpose (على سبيل المثال, testing strength, الشفافية, أو المرونة). Using the wrong material can make your prototype irrelevant to real-world use.

Below is a breakdown of common materials and their ideal use cases, plus key properties to guide your choice:

| نوع المواد | الخصائص الرئيسية | Ideal Prototype Applications | نطاق التكلفة (لكل كجم) |

| السلطة الفلسطينية (نايلون) | صلابة عالية, good impact resistance, مقاومة للارتداء | Prototypes for gears, مفصلات, or parts needing flexibility | \(25- )45 |

| ص (البولي بروبيلين) | خفيف الوزن, مقاوم للمواد الكيميائية, احتكاك منخفض | Food-contact prototypes, containers, or low-stress parts | \(18- )30 |

| PMMA (الأكريليك) | شفافية عالية (92% انتقال الضوء), rigid, easy to polish | Transparent prototypes: الحالات عرض, العدسات, or cosmetic packaging | \(20- )35 |

| القيمة المطلقة الشفافة | Better impact resistance than PMMA, moderate transparency | Transparent prototypes needing durability (على سبيل المثال, electronic enclosures) | \(28- )42 |

| جهاز كمبيوتر شفاف (البولي) | Highest impact resistance among transparent plastics, مقاوم للحرارة (up to 120°C) | Transparent prototypes for high-stress or high-temperature use (على سبيل المثال, قطع غيار السيارات) | \(35- )50 |

للنصيحة: للنماذج الأولية الوظيفية (testing how a part works), prioritize materials that mirror the final product. For visual prototypes (only showing form), you can opt for more cost-effective options if performance isn’t critical.

2. Dimensional Precision: Ensure Alignment with Drawings

CNC machining is famous for its precision—but that doesn’t mean mistakes don’t happen. Even a 0.1mm discrepancy between the machined prototype and your design 图纸 (drawing) can cause fit issues (على سبيل المثال, parts not assembling correctly) or render the prototype useless for testing.

To maintain dimensional accuracy:

- Use detailed, clear drawings: Include exact measurements, tolerances (على سبيل المثال, ±0.05mm for critical features), and material specs. Avoid vague notes like “approximate size.”

- Confirm discrepancies immediately: If during machining you notice even a tiny difference between the workpiece and the drawing, stop and consult your management team or CNC programmer. Don’t assume “small errors are okay”—they often snowball into bigger problems.

- Calibrate tools regularly: Dull or misaligned CNC tools can cause dimensional errors. According to a 2024 industry survey, 32% of CNC prototype defects stem from uncalibrated tools.

3. Program Check: Avoid Errors After Interruptions

CNC prototype machining relies on pre-written programs to guide the machine. If the program is interrupted (على سبيل المثال, power outage, tool breakage, or material jams), modifying the program and resuming without checks is a recipe for disaster.

Follow these steps to ensure program accuracy post-interruption:

- Review the modified code: Check for typos, incorrect coordinates, or missing commands. Even a single wrong digit can lead to the machine cutting in the wrong place.

- Run a dry test: Before machining the actual prototype, run the modified program with the machine empty (no material). This lets you spot issues like tool collisions or incorrect movement paths.

- Inspect the first cut: After resuming, stop the machine after the first few cuts and measure the workpiece. Confirm it matches the drawing before continuing.

Industry data shows that 70% of post-interruption errors can be prevented with these three steps (source: CNC Machining Excellence Report 2024).

4. Bubble Handling: Critical for Silicone-Based Prototypes

If your CNC prototype uses silicone (على سبيل المثال, for molds or flexible parts), bubbles in the silicone can ruin surface finish and structural integrity. Bubbles form when mixing silicone with curing agents—here’s how to eliminate them:

Two Effective Bubble-Removal Methods:

- طريقة 1: Use a vacuum machine: Place the mixed silicone (السيليكون + curing agent) in a vacuum chamber and apply -0.095 MPa pressure for 5–10 minutes. This removes 95%+ of bubbles (the most reliable method for high-precision prototypes).

- طريقة 2: Adjust curing agent ratio: Reduce the curing agent amount by 5–10% (from the manufacturer’s recommended ratio). This slows down the curing process, giving bubbles more time to rise to the surface. ملحوظة: Only use this for non-critical prototypes—too little curing agent can weaken the silicone.

تحذير: Bubbles larger than 2mm can cause cracks in the prototype during testing. Always inspect silicone parts for bubbles before moving to the next step.

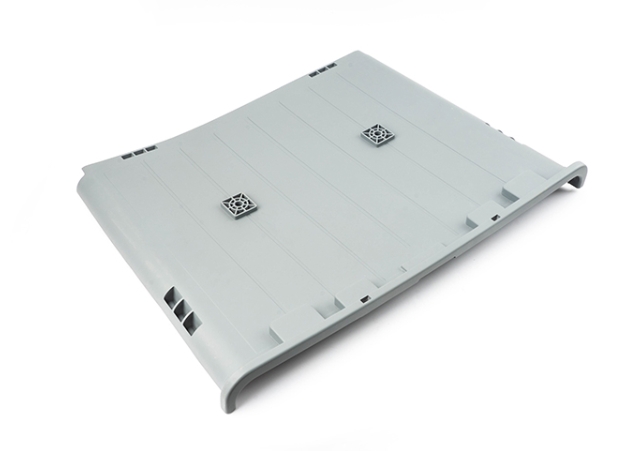

5. Surface Treatment: Boost Aesthetics and Functionality

For many prototypes—especially visual or client-facing ones—surface finish matters. Poorly finished prototypes can give the wrong impression of your final product. The most common surface treatment for CNC prototypes is polishing, especially for transparent materials like PMMA or transparent PC.

How to Polish Transparent CNC Prototypes for Maximum Clarity:

- Start with coarse sandpaper: Use 400–600 grit sandpaper to smooth out machining marks. Sand in circular motions with light pressure.

- Move to fine sandpaper: Switch to 800–1200 grit sandpaper to refine the surface. This removes scratches from the coarse sandpaper.

- Use polishing compound: Apply a plastic polishing compound (على سبيل المثال, cerium oxide) with a soft cloth or polishing wheel. Buff at low speed (500–800 RPM) until the surface reaches 90%+ transparency—matching the clarity of the final product.

For non-transparent prototypes (على سبيل المثال, PA or PP), you can also use painting or anodizing (for metals) to improve appearance.

6. Avoid Bonding: Prioritize One-Piece Machining for Certain Materials

Some materials—like السلطة الفلسطينية (نايلون) و ص (البولي بروبيلين)—have low surface energy, which means adhesives (even industrial-grade ones) won’t bond them well. Bonded PA/PP prototypes often split apart during testing, leading to failed validation.

The solution? One-piece machining:

- Instead of cutting the prototype into multiple parts and gluing them together, machine the entire prototype from a single block of material.

- This approach increases structural integrity by 40–60% for PA/PP prototypes (source: Material Science for Prototyping Journal).

Exceptions: If the prototype is too large for one-piece machining (على سبيل المثال, over 500mm in length), use mechanical fasteners (على سبيل المثال, مسامير) instead of adhesives for PA/PP parts.

7. Prototype Validation: Use Machined Prototypes to De-Risk Development

CNC prototypes aren’t just for show—they’re critical for validating your design. Skipping validation can lead to costly mistakes in mass production. Here’s how to use your CNC prototype effectively:

- Test fit and assembly: Check if the prototype fits with other components (على سبيل المثال, a gear fitting into a housing). Look for tight spots or gaps that need design adjustments.

- Evaluate functionality: If the prototype is functional (على سبيل المثال, a moving part), test its performance under real-world conditions (على سبيل المثال, repeated use, تغيرات درجة الحرارة).

- جمع ردود الفعل: Share the prototype with stakeholders (المهندسون, العملاء, or end-users) to identify design flaws you might have missed.

أ 2023 study found that teams that validate CNC prototypes reduce final product defects by 35% compared to those that skip this step.

8. Equipment Maintenance: Keep CNC Machines Calibrated

Even the best CNC machines lose precision over time without maintenance. Regular upkeep ensures your machine delivers consistent results for every prototype.

Follow this maintenance schedule (recommended by CNC machine manufacturers):

| Maintenance Task | Frequency | Purpose |

| Clean tool holders and spindle | After every 5 jobs | Prevent tool slippage and ensure accurate cutting |

| Calibrate linear axes | Monthly | Maintain dimensional accuracy (avoids ±0.02mm+ errors) |

| Check coolant levels | Weekly | Prevent tool overheating and extend tool life |

| Inspect belts and gears | Quarterly | Avoid unexpected machine downtime |

Data Note: Machines that follow this schedule have a 25% انخفاض معدل الفشل and produce prototypes with 98% دقة (مقابل. 82% for unmaintained machines) (source: CNC Equipment Maintenance Survey).

9. Operator Training: Ensure Safe, Accurate Machining

CNC machines are powerful tools—untrained operators can cause accidents, damage equipment, or produce faulty prototypes. All operators should complete professional training covering:

- Machine operation: How to load materials, set up tools, and start/stop programs safely.

- Safety protocols: Using personal protective equipment (PPE: goggles, gloves), handling emergencies (على سبيل المثال, tool breakage), and avoiding contact with moving parts.

- Troubleshooting basics: Identifying common issues (على سبيل المثال, poor surface finish, dimensional errors) and knowing when to pause machining.

According to OSHA (Occupational Safety and Health Administration), 60% of CNC-related accidents are caused by untrained operators. Investing in training saves time, مال, and lives.

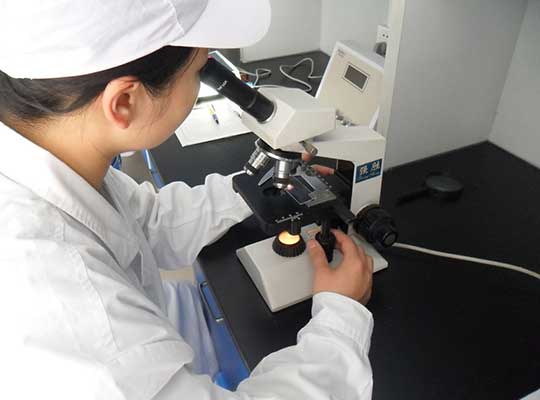

10. ضبط الجودة: Monitor Every Step of the Process

ضبط الجودة (QC) isn’t a one-time check at the end—it should happen throughout CNC prototype machining. Here’s how to implement effective QC:

- Pre-machining check: Verify material type, drawing accuracy, and tool calibration before starting.

- In-process checks: Stop machining at key stages (على سبيل المثال, after rough cutting, before finishing) to measure dimensions with tools like calipers or micrometers.

- Final inspection: بعد الآلات, check the prototype against the drawing for:

- دقة الأبعاد (all measurements within tolerance).

- الانتهاء من السطح (no scratches, فقاعات, or uneven areas).

- الوظيفة (إذا كان ذلك ممكنا: moving parts work, parts fit together).

Use a QC checklist to ensure no steps are missed—this reduces the chance of faulty prototypes by 50% (source: Manufacturing Quality Assurance Report).

Yigu Technology’s Perspective on CNC Prototype Machining

في Yigu Technology, we see CNC prototype machining as the backbone of successful product development. For our clients, the top priorities are accuracy and efficiency—so we emphasize material-matching (على سبيل المثال, using PMMA for transparent parts, PA for tough components) and in-process QC to catch issues early. We also train our operators rigorously and maintain machines on a strict schedule, ensuring prototypes meet 99% of drawing tolerances. For clients new to CNC machining, we often recommend one-piece machining for PA/PP parts to avoid bonding failures. Ultimately, following these considerations turns CNC machining from a complex process into a reliable way to de-risk product development.

التعليمات:

1. How long does CNC prototype machining take?

It depends on the prototype’s size and complexity. نماذج أولية بسيطة (على سبيل المثال, small plastic parts) take 1–3 days, while large or detailed ones (على سبيل المثال, metal components with tight tolerances) can take 5–7 days. Adding surface treatment (like polishing) may add 1–2 extra days.

2. Can CNC prototypes be made from metal?

نعم! CNC machines can machine metal materials like aluminum, الفولاذ المقاوم للصدأ, and titanium for prototypes. Metal prototypes are ideal for testing strength or heat resistance (على سبيل المثال, automotive or aerospace parts), but they cost more (\(50- )150 لكل كجم) and take longer to machine than plastic prototypes.

3. What if my CNC prototype has dimensional errors?

أولاً, identify the cause: check if tools are calibrated, if the program has errors, or if the material shifted during machining. If the error is small (within ±0.1mm for non-critical features), you may be able to fix it with minor polishing. For larger errors, re-machine the prototype—don’t try to “adjust” it with adhesives or sanding, as this will compromise functionality.