If you’re a product developer or designer, one of the most pressing questions you’ll have is: how long does rapid prototype lead time take? The answer isn’t a simple number—several key factors directly impact how quickly you can get your prototype in hand. في هذا الدليل, we’ll break down each factor, provide real-world timelines, and help you understand how to optimize your prototype schedule.

Key Factors That Affect Rapid Prototype Lead Time

Rapid prototype lead time isn’t a one-size-fits-all metric. It depends on four critical elements: design complexity, اختيار المواد, manufacturing method, and sample quantity. Below is a detailed breakdown of each factor, along with how it influences your timeline.

| عامل | Impact on Lead Time | Typical Time Range (Add-On) |

| تعقيد التصميم | More details (على سبيل المثال, ثقوب صغيرة, curved surfaces) = longer programming/setup time | 1-5 أيام |

| Material Choice | Harder materials = slower machining; softer materials = faster processing | 0.5-3 أيام |

| Manufacturing Method | Manual = faster for simple parts; CNC/3D Printing = longer setup but faster production | 1–4 days |

| Sample Quantity | More samples = longer production time (but economies of scale apply) | 0.5–2 days per 5 additional units |

1. تعقيد التصميم: The Foundation of Lead Time

Your prototype’s design complexity is the biggest driver of lead time. A simple part (like a flat plastic bracket) will be ready much faster than a complex component (like a medical device with tiny internal channels). Here’s why:

- Simple designs (على سبيل المثال, basic shapes, no intricate details) require minimal programming for CNC machines or 3D printers. Setup time is often just 1–2 hours, and production can start immediately.

- تصميمات معقدة (على سبيل المثال, تقف, الجدران الرقيقة, multiple surfaces) need detailed 3D modeling checks, toolpath adjustments, and quality control steps. على سبيل المثال, a prototype with 10+ ثقوب صغيرة (less than 2mm in diameter) may add 3–5 days to your lead time because the machine needs to run slower to avoid tool breakage.

للنصيحة: If you’re in a hurry, work with your designer to simplify non-critical features first. This can cut your lead time by up to 30%.

2. Material Choice: Hardness and Processability Matter

The material you choose for your rapid prototype directly affects how long it takes to manufacture. Different materials have unique properties that impact machining speed and difficulty. Here are common materials and their typical lead time impacts:

| نوع المواد | Hardness Level | Machining Speed | Lead Time Impact | الأفضل ل |

| PMMA (الأكريليك) | ناعم | سريع (50mm/min) | الحد الأدنى (+0.5 أيام) | أجزاء شفافة, displays |

| ABS البلاستيك | واسطة | معتدل (35mm/min) | قليل (+1 يوم) | Consumer electronics, حاويات |

| الألومنيوم (6061) | Medium-Hard | معتدل (25mm/min) | واسطة (+2 أيام) | Lightweight structural parts |

| الفولاذ المقاوم للصدأ (304) | Hard | بطيئة (15mm/min) | عالي (+3 أيام) | Industrial components, high-strength parts |

على سبيل المثال: A stainless steel prototype will take 2–3 days longer to make than an identical PMMA prototype because the machine must use specialized tools and slower cutting speeds to avoid overheating.

3. Manufacturing Method: Speed vs. دقة

The way you make your rapid prototype—whether manual, تصنيع CNC, or 3D printing—plays a big role in lead time. Each method has trade-offs between speed and precision:

- Manual Prototyping: Best for simple parts (على سبيل المثال, foam models, basic plastic shapes). Skilled technicians can finish a simple manual prototype in 1–2 days, but it may lack the precision of machine-made parts (تسامح: ±0.2mm). It’s a good choice if you need a quick visual check, not a functional test.

- تصنيع CNC: Ideal for high-precision parts (تسامح: ± 0.05mm). CNC machines need 1–2 days of setup (programming, tool selection) but can produce parts quickly once running. A typical CNC prototype takes 3–7 days total.

- 3د الطباعة (FDM/SLA): Great for complex geometries (على سبيل المثال, lattice structures). FDM (نمذجة ترسب تنصهر) is faster (2-5 أيام المجموع), while SLA (مجسم) offers better detail but adds 1–2 days. 3D printing is perfect for functional prototypes that need to mimic final product properties.

4. Sample Quantity: Small Batches = Faster Turnaround

Rapid prototyping is designed for small batches—and that’s a good thing for lead time. Most projects order 1–10 samples, which keeps production efficient. Here’s how quantity affects time:

- 1–3 samples: The fastest option. Machines can run continuously without reloading materials or adjusting settings. Lead time: 3-5 أيام (for simple designs).

- 4–10 samples: Adds 1–2 days. You may need to reload materials once, but there’s still no major setup change.

- 11+ samples: Lead time increases by 0.5–1 day per 5 additional units. At this point, you’re moving from “prototyping” to “small-batch production,” which requires more quality checks.

Remember: Ordering 2–3 samples instead of 1 is often worth it. It lets you test different use cases and catch issues faster—saving time in the long run.

Typical Rapid Prototype Lead Time: أمثلة في العالم الحقيقي

To make this concrete, let’s look at three common scenarios. These timelines include design review, تصنيع, and quality control (QC):

- سيناريو 1: Simple ABS Plastic Bracket (تصنيع CNC)

- Design: Flat bracket with 2 ثقوب (no complex details)

- مادة: ABS البلاستيك

- Quantity: 2 samples

- Total Lead Time: 3–4 days

- Breakdown: 1 يوم (design review) + 2 أيام (تصنيع CNC) + 0.5 أيام (QC)

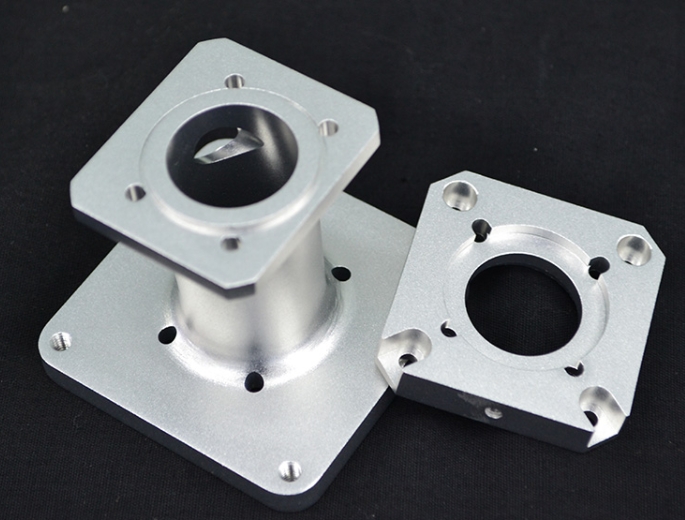

- سيناريو 2: Complex Stainless Steel Valve (تصنيع CNC)

- Design: Internal channels, 5 ثقوب صغيرة (1mm diameter)

- مادة: الفولاذ المقاوم للصدأ 304

- Quantity: 1 sample

- Total Lead Time: 7–9 days

- Breakdown: 2 أيام (design review + programming) + 5 أيام (تصنيع CNC) + 1 يوم (QC)

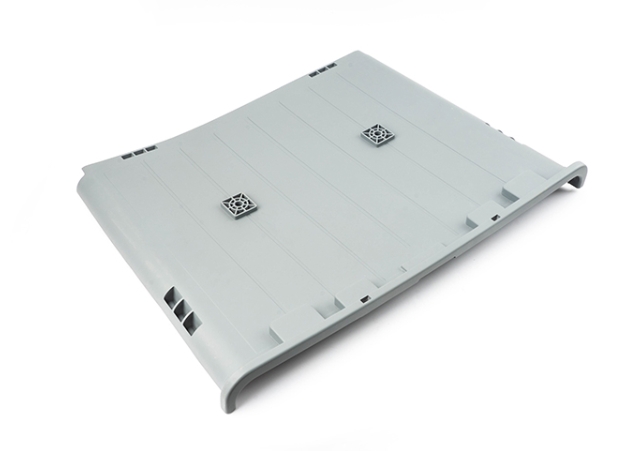

- سيناريو 3: Transparent PMMA Enclosure (3د الطباعة)

- Design: الأسطح المنحنية, no undercuts

- مادة: PMMA (SLA 3D Printing)

- Quantity: 3 samples

- Total Lead Time: 4–6 days

- Breakdown: 1 يوم (design review) + 3 أيام (3د الطباعة + ما بعد المعالجة) + 0.5 أيام (QC)

Yigu Technology’s Perspective on Rapid Prototype Lead Time

في Yigu Technology, we believe rapid prototype lead time should balance speed and quality—rushing a prototype often leads to costly reworks. Our team optimizes timelines by: 1) Using advanced CNC and 3D printing equipment to cut setup time by 20%; 2) Offering material pre-selection guides to help clients choose fast-processing options without sacrificing performance; 3) Providing 24-hour design reviews to catch issues early. For most projects, we deliver simple prototypes in 3–4 days and complex ones in 7–10 days—all while maintaining ±0.05mm precision. We prioritize clear communication, so clients always know their prototype’s status and can adjust timelines if needed.

التعليمات:

1. Can I get a rapid prototype in less than 3 أيام?

نعم, but it depends on the design and method. Simple manual prototypes (على سبيل المثال, foam models) can be ready in 1–2 days, and some 3D printing services offer “24-hour rush” options for basic parts. لكن, rush orders may cost 50–100% more and may skip non-critical QC steps.

2. Does adding post-processing (على سبيل المثال, تلوين, polishing) increase lead time?

قطعاً. Post-processing steps like painting, polishing, or annealing add 1–3 days to your timeline. على سبيل المثال, a polished aluminum prototype will take 2 extra days compared to an unpolished one. Discuss post-processing needs with your manufacturer early to avoid delays.

3. How can I reduce my rapid prototype lead time without cutting corners?

Focus on three steps: 1) Share a complete, error-free 3D model (this eliminates design review delays); 2) Choose a material that’s easy to machine (على سبيل المثال, ABS instead of stainless steel) if it meets your test needs; 3) Work with a manufacturer that offers in-house design support—they can spot issues before production starts, saving days of rework.