Hadfield steel (also known as manganese steel or 11-14% الصلب المنغنيز) is a unique high-manganese alloy steel celebrated for its exceptional ارتداء المقاومة و تصلب العمل ability—traits driven by its distinctive التكوين الكيميائي (high manganese, الكربون المتوسط) and specialized heat treatment. Unlike standard carbon or alloy steels, Hadfield steel gets harder when subjected to impact or pressure (rather than cracking), making it a top choice for industries where extreme abrasion and impact are common, such as mining, بناء, إعادة التدوير, والزراعة. في هذا الدليل, سنقوم بتفكيك خصائصها الرئيسية, استخدامات العالم الحقيقي, تقنيات الإنتاج, وكيف تقارن بالمواد الأخرى, helping you select it for projects that demand long-lasting durability in harsh conditions.

1. Key Material Properties of Hadfield Steel

Hadfield steel’s performance lies in its high-manganese composition, which creates austenitic microstructure—responsible for its unique work hardening behavior and resistance to wear.

التكوين الكيميائي

Hadfield steel’s formula prioritizes work hardening and wear resistance, with strict ranges for key elements (per ASTM A128 standards):

- المنغنيز (MN): 11.00-14.00% (core element—forms austenitic microstructure, enabling work hardening and preventing brittle failure under impact)

- الكربون (ج): 1.00-1.40% (medium content stabilizes austenite and forms hard carbides, تعزيز ارتداء المقاومة)

- السيليكون (و): 0.30-1.00% (aids deoxidation during steelmaking and improves high-temperature stability for casting)

- الفسفور (ص): ≤0.070% (controlled to avoid cold brittleness, though higher than standard steels—acceptable for impact-focused applications)

- الكبريت (ق): ≤0.050 ٪ (limited to prevent hot cracking during casting and ensure uniform work hardening)

- الكروم (كر): ≤0.50 ٪ (optional trace addition—enhances corrosion resistance for outdoor or moist environments like mining)

- النيكل (في): ≤0.50 ٪ (optional trace addition—improves toughness at low temperatures for cold-climate construction)

- الموليبدينوم (شهر): ≤0.30 ٪ (optional trace addition—boosts high-temperature strength for industrial equipment like grinding mills)

الخصائص الفيزيائية

| ملكية | Typical Value for Hadfield Steel |

| كثافة | ~7.80 g/cm³ (slightly lower than carbon steel, no significant weight impact for heavy-duty parts) |

| نقطة الانصهار | ~1430-1480°C (suitable for casting and hot working of thick-walled parts like crusher jaws) |

| الموصلية الحرارية | ~ 25 ث/(م · ك) (عند 20 درجة مئوية - أقل من الصلب الكربوني, but sufficient for heat dissipation in impact-heavy applications) |

| سعة حرارة محددة | ~0.50 kJ/(كجم · ك) (في 20 درجة مئوية) |

| معامل التمدد الحراري | ~18 x 10⁻⁶/°C (20-500°C—higher than standard steels, requiring careful design to avoid thermal stress in welded parts) |

الخصائص الميكانيكية

Hadfield steel’s mechanical properties are unique—its initial softness gives way to extreme hardness after work hardening:

- قوة الشد (initial, صلب): ~620 MPa (rises to 1200+ MPa after work hardening—ideal for impact-loaded parts like excavator buckets)

- قوة العائد (initial, صلب): ~275 MPa (low initially, but increases dramatically with wear—prevents permanent deformation under pressure)

- استطالة (initial, صلب): ≥ 40 ٪ (excellent ductility—enables forming of large parts like grinding mill liners without cracking)

- صلابة (initial, برينيل): ~220-250 HB (soft enough for casting; rises to 500+ HB after work hardening—rivaling some tool steels)

- مقاومة التأثير (Charpy V-Notch, 20درجة مئوية): ≥200 J (exceptional—withstands heavy impacts from rocks, أسمنت, or metal scraps without breaking)

- مقاومة التعب: ~200-250 MPa (at 10⁷ cycles—suitable for dynamic-impact parts like crusher hammers, though less critical than wear resistance)

- Work hardening rate: عالية جدا (hardens 2-3x faster than carbon steel under impact—key to its long service life in abrasive conditions)

خصائص أخرى

- مقاومة التآكل: معتدل (لا توجد إضافات سبائك لحماية الصدأ المحسنة; prone to rust in moist environments—requires painting or galvanizing for outdoor use, though wear often outpaces corrosion in harsh applications)

- قابلية اللحام: عدل (austenitic microstructure requires specialized techniques—low-hydrogen electrodes, preheating to 300-400°C, and post-weld annealing to avoid cracking; welding is rarely used for critical wear surfaces)

- القابلية للآلات: فقير (initial softness leads to “gumming” of tools; conventional machining is impractical—parts are typically cast to final shape or finished with grinding)

- ليونة: ممتاز (initial ductility allows casting of complex shapes like custom crusher jaws or shredder blades)

- ارتداء المقاومة: ممتاز (after work hardening—5-10x more wear-resistant than carbon steel in mining or construction applications)

2. Real-World Applications of Hadfield Steel

Hadfield steel’s work hardening ability and impact resistance make it indispensable in industries where standard materials wear out quickly. فيما يلي استخداماتها الأكثر شيوعًا:

التعدين

- كسارات: Jaw crushers, الكسارات المخروطية, and impact crushers use Hadfield steel for jaws, بطانات, and hammers—تصلب العمل resists wear from rocks and ores, extending part life by 3-5x vs. الصلب الكربوني.

- Grinders: Ball mills and rod mills use Hadfield steel for grinding balls and liners—ارتداء المقاومة handles abrasive minerals like coal or iron ore, تقليل تردد الاستبدال 70%.

- Jaw plates: Primary crusher jaw plates (handling rocks up to 1 meter in diameter) use Hadfield steel—مقاومة التأثير (≥200 J) withstands heavy rock impacts without cracking, توفير $50,000+ سنويا في قطع الغيار.

- Hammer plates: Impact crusher hammer plates use Hadfield steel—تصلب العمل ensures edges stay sharp, even after crushing thousands of tons of material.

مثال القضية: A mining company used alloy steel for ball mill liners but faced replacement every 6 شهور. Switching to Hadfield steel extended liner life to 24 شهور (300% أطول)-توفير $120,000 annually in liner costs and reducing mill downtime by 40%.

بناء

- شفرات الجرافات: Heavy-duty bulldozer blades (for mining or road construction) use Hadfield steel—ارتداء المقاومة handles gravel, الصخور, والحطام الملموسة, extending blade life by 2-3x vs. الصلب الكربوني.

- دلاء حفارة: Mining excavator buckets (capacity 10+ cubic meters) use Hadfield steel for bucket lips and teeth—مقاومة التأثير withstands digging into hard rock, reducing tooth replacement by 60%.

- Road milling machines: Road milling drums and cutting teeth use Hadfield steel—ارتداء المقاومة grinds asphalt and concrete without dulling, extending drum life by 150% and lowering road repair costs.

إعادة التدوير

- التقطيع: Metal shredders (for car bodies or scrap metal) use Hadfield steel for shredder hammers and screens—تصلب العمل resists wear from metal scraps, extending hammer life by 4x vs. سبيكة الصلب.

- مقصات: Scrap metal shears (cutting steel beams or pipes) use Hadfield steel for shear blades—مقاومة التأثير handles thick metal without blade chipping, تقليل وقت التوقف عن الصيانة 50%.

- Compactors: Waste compactors (for construction or industrial waste) use Hadfield steel for compactor plates—ارتداء المقاومة withstands sharp debris like nails or glass, extending plate life by 3x.

زراعة

- المحرث: محرث الشاقة (for rocky or clay soils) use Hadfield steel—ارتداء المقاومة handles soil abrasion, extending plow life by 2-3x vs. carbon steel and reducing fuel consumption (sharper plows require less power).

- Harrow discs: Agricultural harrow discs (for tilling or seedbed preparation) use Hadfield steel—تصلب العمل ensures discs stay flat and sharp, even after passing over rocks, improving soil tillage quality.

- Soil tillage equipment: Rotary tiller blades and cultivator tines use Hadfield steel—مقاومة التأثير withstands hidden rocks, reducing blade breakage by 70% during planting seasons.

صناعي

- أنظمة النقل: Mining or quarry conveyor rollers and scraper blades use Hadfield steel—ارتداء المقاومة handles abrasive materials like gravel or coal, extending roller life by 2x and reducing conveyor downtime.

- Industrial wear parts: Cement mixer liners and asphalt plant components use Hadfield steel—مقاومة الحرارة (ما يصل إلى 500 درجة مئوية) and wear resistance withstand high temperatures and abrasive materials, extending part life by 3x.

- طحن الطاحونة بطانات: Cement or mineral grinding mill liners use Hadfield steel—تصلب العمل resists grinding media impact, reducing liner replacement by 80% and lowering production costs.

3. Manufacturing Techniques for Hadfield Steel

Producing Hadfield steel requires specialized casting and heat treatment to preserve its austenitic microstructure—critical for work hardening. إليك العملية التفصيلية:

1. الإنتاج الأولي

- صناعة الصلب:

- فرن القوس الكهربائي (EAF): الطريقة الأساسية - الصلب scrap, high-manganese ore, and carbon are melted at 1650-1750°C. Manganese is added in large quantities (11-14%) to form the austenitic structure; carbon is adjusted to 1.00-1.40% to stabilize austenite.

- فرن الأكسجين الأساسي (bof): Rarely used—EAF is preferred for precise control of manganese content, which is critical for Hadfield steel’s properties.

- فرن الصهر: Manganese ore is smelted into ferromanganese (an alloy of iron and manganese) in a blast furnace—ferromanganese is then added to the EAF to reach Hadfield steel’s manganese requirements.

2. المعالجة الثانوية

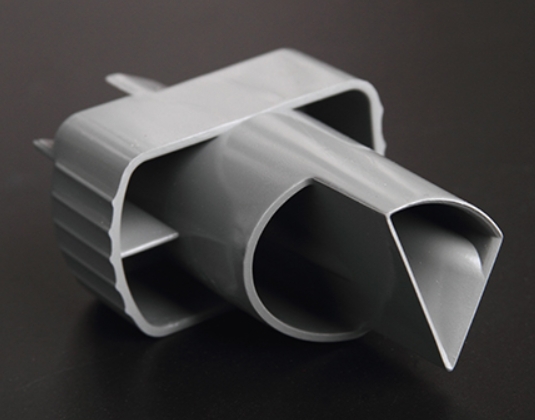

- صب: Molten Hadfield steel is cast into shapes (على سبيل المثال, الفكين الكساري, bucket lips, كرات طحن) via sand casting or investment casting—casting is the primary method, as machining is impractical. Casting ensures complex shapes and uniform manganese distribution.

- المتداول: للأجزاء المسطحة (على سبيل المثال, conveyor plates or blade blanks), cast ingots are heated to 1100-1150°C and hot-rolled into plates—hot rolling refines grain structure but must be done carefully to avoid premature work hardening.

- تزوير: لأجزاء عالية القوة (على سبيل المثال, shredder hammers), cast blanks are heated to 1050-1100°C and forged into shape—forging improves material density, enhancing impact resistance, but is less common than casting due to cost.

- المعالجة الحرارية:

- الحل الصلب: The most critical step—cast or rolled parts are heated to 1050-1100°C for 2-4 ساعات, ثم يلفت المياه. This dissolves carbides into the austenitic matrix, preserving the microstructure needed for work hardening. Slow cooling would cause carbide precipitation, ruining work hardening ability.

- تقع: Not required—solution annealing followed by quenching is the only heat treatment needed; tempering would reduce ductility and work hardening potential.

3. المعالجة السطحية

- تلوين: Epoxy or polyurethane paints are applied to non-wear surfaces (على سبيل المثال, crusher frames or conveyor supports)—prevents rust in moist environments like mines or quarries.

- التفجير: Shot blasting removes surface scale from cast parts—improves appearance and ensures uniform work hardening on wear surfaces.

- Corrosion protection: للأجزاء الخارجية (على سبيل المثال, شفرات الجرافات), zinc-rich primers are used—adds a thin corrosion barrier, though wear often removes the coating from critical surfaces (work hardening then takes over as the primary protection).

- طلاء: Rarely used on wear surfaces—coatings would prevent direct impact, hindering work hardening; only applied to non-impact areas for corrosion control.

4. ضبط الجودة

- تقتيش: Visual inspection checks for casting defects (على سبيل المثال, المسامية, تشققات) in Hadfield steel parts—critical for impact-focused applications, as defects can lead to premature failure.

- الاختبار:

- التحليل الكيميائي: Ensures manganese (11-14%) والكربون (1.0-1.4%) content meet ASTM A128 standards—manganese levels outside this range destroy work hardening ability.

- اختبار التأثير: Charpy V-notch tests verify impact resistance (≥200 J)—confirms the material can withstand heavy impacts without breaking.

- اختبار الصلابة: Initial Brinell hardness (220-250 HB) is measured—ensures the material is soft enough for casting and will work harden properly.

- اختبار غير التدمير: Ultrasonic testing detects internal casting defects (على سبيل المثال, الفراغات) in thick parts like crusher jaws—avoids catastrophic failure under impact.

- شهادة: Each batch of Hadfield steel receives an ASTM A128 certificate, verifying chemical composition and mechanical properties—mandatory for mining, بناء, or industrial applications.

4. دراسة حالة: Hadfield Steel in Metal Shredder Hammers

A recycling company used D2 tool steel for metal shredder hammers but faced replacement every 2 شهور (due to chipping and wear) and high maintenance costs. Switching to Hadfield steel delivered transformative results:

- Hammer Life Extension: Hadfield steel’s تصلب العمل و مقاومة التأثير extended hammer life to 8 شهور (300% أطول)—cutting hammer replacement frequency by 75% والادخار $80,000 سنويا.

- تحسين الأداء: Hadfield steel hammers maintained sharp edges longer, increasing shredding efficiency by 20% (more metal processed per hour) and boosting monthly recycling capacity by 500 طن.

- وفورات التكلفة: Despite Hadfield steel’s 40% ارتفاع تكلفة المواد, longer life and better efficiency saved the company $192,000 annually—achieving ROI in just 1.5 شهور.

5. Hadfield Steel vs. مواد أخرى

How does Hadfield steel compare to other wear-resistant materials? الجدول أدناه يسلط الضوء على الاختلافات الرئيسية:

| مادة | يكلف (مقابل. Hadfield Steel) | صلابة أولية (HB) | القدرة على تصلب العمل | مقاومة التأثير (ي) | ارتداء المقاومة (نسبي) |

| Hadfield Steel | قاعدة (100%) | 220-250 | ممتاز | ≥200 | 100 (Reference) |

| الصلب الكربوني (A36) | 50% | 110-130 | فقير | 40-60 | 10 |

| سبيكة الصلب (4140) | 80% | 200-230 | عدل | 80-100 | 30 |

| أداة الصلب (D2) | 250% | 600-620 | فقير | 15-25 | 80 |

| Abrasion-Resistant Steel (AR500) | 120% | 470-510 | فقير جدا | 30-40 | 90 |

ملاءمة التطبيق

- Impact-Abrasive Environments: Hadfield steel outperforms all other materials—its work hardening and impact resistance make it the only choice for crusher jaws, shredder hammers, or excavator buckets.

- Low-Impact Wear: AR500 is cheaper and harder initially—better for static wear (على سبيل المثال, conveyor liners with no impact), but fails quickly under impact.

- Precision Parts: أداة الصلب (D2) is better for small, sharp parts (على سبيل المثال, cutting blades) but chips under heavy impact—no match for Hadfield steel in mining or construction.

- حساسة للتكلفة, Low-Wear: Carbon steel is cheapest but wears out 10x faster—only suitable for non-critical parts like temporary supports.

Yigu Technology’s View on Hadfield Steel

في Yigu Technology, Hadfield steel stands out as the gold standard for extreme impact-abrasive applications. إنه unmatched work hardening ability و مقاومة التأثير make it ideal for clients in mining, إعادة التدوير, and heavy construction—where standard materials fail to meet durability needs. We recommend Hadfield steel for crusher jaws, shredder hammers, and excavator buckets—where it outperforms AR500 or tool steel in both life span and cost efficiency. While it’s less machinable, its long service life and low maintenance deliver exceptional ROI. Hadfield steel aligns with our goal of providing tough, sustainable solutions that reduce downtime and lower total ownership costs for industrial clients.