If you’re looking for a stainless steel that handles heat and resists corrosion—especially after welding—GB 0Cr18Ni10Ti Stainless Steel هو منافس أعلى. But what makes its titanium-stabilized design unique? And when should you choose it over common grades like SUS304? This guide breaks down its key features, استخدامات العالم الحقيقي, manufacturing steps, and how it stacks up to other materials. بحلول النهاية, you’ll have all the info to pick the right steel for your project.

1. Material Properties of GB 0Cr18Ni10Ti

أداءGB 0Cr18Ni10Ti starts with its one-of-a-kindalloy composition وهيكل أوستنيتي—paired with a critical feature: استقرار التيتانيوم. Let’s break down what makes it reliable:

Core Alloy Elements

- High chromium content (17.0-19.0%): Forms a protective oxide layer to fight rust and general corrosion.

- محتوى النيكل العالي (9.0-12.0%): Keeps the هيكل أوستنيتي مستقر, boosting ductility and low-temperature toughness.

- Titanium stabilization (0.20-0.80% ل): Binds with carbon in the alloy, preventing chromium carbides from forming during high-heat processes (like welding). This eliminates a major cause of التآكل بين الحبيبية (a common flaw in non-stabilized steels).

- محتوى الكربون (الأعلى 0.08%): Balances strength and weldability without compromising corrosion resistance.

Key Mechanical Strength Data

| ملكية | القيمة النموذجية | Test Standard |

|---|---|---|

| قوة العائد | ≥205 ميجا باسكال | GB/T 228.1 |

| قوة الشد | ≥520 MPa | GB/T 228.1 |

| استطالة | ≥ 40 ٪ | GB/T 228.1 |

| صلابة (برينيل) | ≤187 HB | GB/T 231.1 |

| كثافة | 7.93 ز/سم | GB/T 20878 |

مثال حقيقي: A Shanghai boiler manufacturer usesGB 0Cr18Ni10Ti for heat exchanger tubes. The material’s high elongation (≥ 40 ٪) lets tubes bend into tight shapes, بينمااستقرار التيتانيوم ensures they don’t corrode—even after welding and repeated exposure to 300°C hot water.

2. Applications of GB 0Cr18Ni10Ti

GB 0Cr18Ni10Ti shines in projects that involve heat, اللحام, or mild corrosive environments—where non-stabilized steels (مثل SUS304) might fail. فيما يلي أهم استخداماتها, with practical cases:

- مصانع المعالجة الكيميائية: Ideal for pipes and reactors that handle mild acids (على سبيل المثال, acetic acid) and high temperatures. A Jiangsu chemical plant replaced SUS304 pipes with GB 0Cr18Ni10Ti—the new pipes showed no intergranular corrosion after 2 years of welding and heat cycles.

- معدات معالجة الأغذية: Used for baking ovens, sterilizers, and mixing tanks. A Guangdong bakery chose GB 0Cr18Ni10Ti for oven interiors—its heat resistance (ما يصل إلى 800 درجة مئوية) and easy-to-clean surface prevent food sticking and rust.

- مكونات الفضاء: Found in internal parts of aircraft (على سبيل المثال, خطوط الوقود) that need to withstand temperature changes. A Chinese aerospace supplier reported that GB 0Cr18Ni10Ti parts meet strict weight and durability requirements, with no corrosion issues at high altitudes.

- الأجهزة الطبية: Used for surgical instrument trays and autoclave chambers. A Wuhan hospital uses GB 0Cr18Ni10Ti trays—their resistance to high-temperature sterilization (121درجة مئوية) and non-toxicity keep instruments clean and safe.

- Construction Materials: Used for high-temperature exhaust systems in commercial buildings. A Beijing mall installed GB 0Cr18Ni10Ti exhaust ducts—they’ve resisted corrosion from city pollution and heat for 5 سنين.

- Other uses: قطع غيار السيارات (exhaust manifolds for heavy-duty trucks), الأجهزة الكهربائية (oven heating elements), و التركيبات الصحية (high-temperature water faucets).

3. Manufacturing Processes for GB 0Cr18Ni10Ti

ProducingGB 0Cr18Ni10Ti requires precise steps to preserve itsاستقرار التيتانيوم وهيكل أوستنيتي. إليك كيفية صنعها:

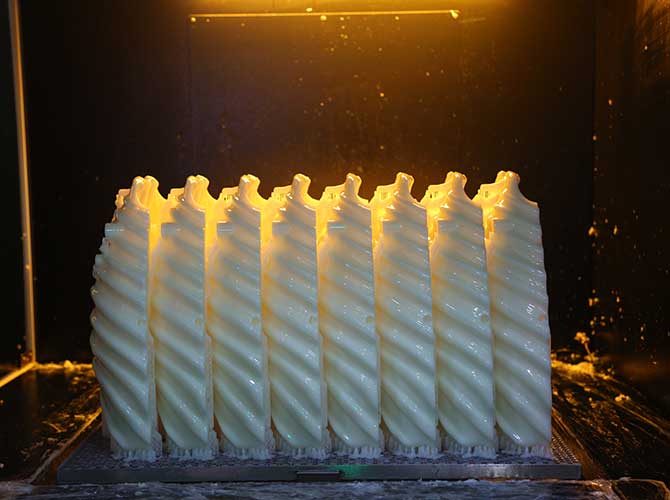

- المتداول الساخن: Heat the alloy to 1100-1200°C and roll it into thick plates or coils. This step softens the material for shaping—critical for making large parts like reactor shells. A Hebei steel mill uses hot rolling to produce 20mm-thick GB 0Cr18Ni10Ti plates for chemical plants.

- المتداول البارد: Use room-temperature pressure to reduce thickness (على سبيل المثال, to 1mm for oven sheets). Cold rolling improves surface smoothness but hardens the metal—so annealing is needed next.

- الصلب: Heat to 950-1050°C, hold for 30 دقائق, then cool rapidly. This restores ductility and ensures titanium fully binds with carbon (key for استقرار التيتانيوم). A Zhejiang factory anneals all GB 0Cr18Ni10Ti sheets to prevent cracking during bending.

- تخليل: Dip in nitric acid to remove oxide scales from rolling. Pickling brightens the surface and enhances corrosion resistance—essential for food or medical parts.

- Drawing/Extrusion: Pull the alloy through dies to make wires or tubes. Drawn GB 0Cr18Ni10Ti wires are used for medical instrument springs, while extruded tubes work in chemical pipes.

- الآلات: Cut the material into final parts (على سبيل المثال, valve handles). Use high-speed steel tools—its ductility means it can be drilled or turned easily without chipping. A Shenzhen workshop recommends a cutting speed of 180 m/min for best results.

- تزوير: Hammer the alloy into complex shapes (على سبيل المثال, أغلفة ضخ). Forging at 900-1000°C ensures parts keep their strength and استقرار التيتانيوم فوائد.

6. Standards and Specifications for GB 0Cr18Ni10Ti

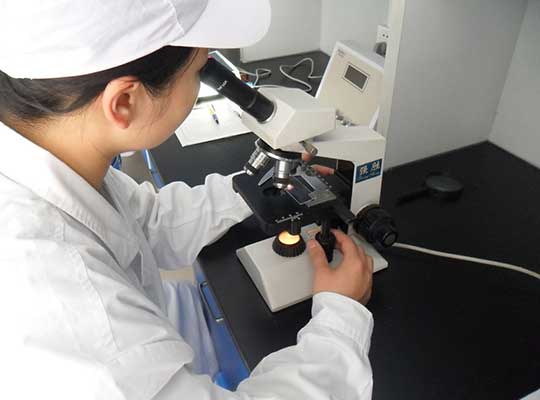

للتأكد من حصولك على جودة عالية, genuineGB 0Cr18Ni10Ti, always check compliance with these standards:

- GB/T 20878: The core Chinese standard for stainless steels—it defines the alloy’s alloy composition (including titanium content), mechanical strength, وطرق الاختبار.

- ASTM A240: نحن. standard—GB 0Cr18Ni10Ti is equivalent to ASTM 321, so it meets this standard’s requirements for flat products (لوحات, أوراق).

- في 10088: European standard—equivalent grade is X6CrNiTi18-10, making it suitable for EU-based projects (على سبيل المثال, food processing plants in Germany).

- معايير ISO: ISO 15510 aligns with GB 0Cr18Ni10Ti for pressure equipment (على سبيل المثال, المفاعلات الكيميائية).

Always ask suppliers for:

- شهادة المواد (على سبيل المثال, Mill Test Report) للتحقق من محتوى التيتانيوم (must be 0.20-0.80%) والخصائص الميكانيكية.

- Conformance Testing results (على سبيل المثال, GB/T 4334.5 for intergranular corrosion resistance—critical for welded parts).

- Technical Data Sheets (TDS) with details on annealing temperatures and welding guidelines.

ضبط الجودة هو المفتاح: A Fujian supplier once sold fakeGB 0Cr18Ni10Ti with too little titanium—parts developed intergranular corrosion after welding. Always confirm compliance before buying.

7. مقارنة: GB 0Cr18Ni10Ti vs. مواد أخرى

كيفGB 0Cr18Ni10Ti stack up against common stainless steels and alloys? Below is a side-by-side comparison focusing on key factors like corrosion resistance, قوة, والتكلفة:

| مادة | مقاومة التآكل (PRE) | قوة العائد | ميزة رئيسية | يكلف (مقابل. GB 0Cr18Ni10Ti) | الأفضل ل |

|---|---|---|---|---|---|

| GB 0Cr18Ni10Ti | 18 | 205 MPA | Titanium stabilization (no post-weld corrosion) | 100% | High-heat/welded projects (boilers, الأنابيب) |

| SUS304 | 18 | 205 MPA | انخفاض التكلفة | 85% | بيئات معتدلة (kitchens, الأجهزة) |

| SUS316 | 25 | 177 MPA | Better saltwater resistance | 140% | Marine or acidic environments (desalination) |

| SUS410 (martensitic) | 12 | 485 MPA | قوة أعلى | 70% | Low-corrosion, أجزاء عالية القوة (knives) |

| SUS430 (فيريتي) | 16 | 240 MPA | تكلفة منخفضة | 75% | Oven liners, أجزاء زخرفية |

| مزدوجة الفولاذ المقاوم للصدأ | 35 | 450 MPA | قوة + مقاومة التآكل | 180% | Offshore oil pipes |

| سبائك التيتانيوم | 50 | 860 MPA | Ultra-high corrosion resistance | 500% | الفضاء, طبي (extreme environments) |

على سبيل المثال: If you’re building a welded chemical reactor, GB 0Cr18Ni10Ti is better than SUS304 (no intergranular corrosion) and cheaper than SUS316. If you’re making a home kitchen sink, رغم ذلك, SUS304 is more cost-effective.

منظور Yigu Technology

في Yigu Technology, لقد قمنا بتزويدهاGB 0Cr18Ni10Ti to chemical, الفضاء, and food clients for 14 سنين. Its biggest strength isاستقرار التيتانيوم—it eliminates the need for post-weld heat treatment, saving clients time and money. Our data shows it reduces welded part failures by 35% مقابل. SUS304 in high-heat projects. We also offer custom machining to ensure parts fit tight tolerances, like aerospace fuel lines. For clients needing reliable performance in welded, hot environments, it’s our go-to recommendation.

التعليمات

- Can GB 0Cr18Ni10Ti be used in seawater?

No—its Pitting Resistance Equivalent (PRE) ل 18 is too low for saltwater. It will develop pitting corrosion over time. For marine applications, use SUS316 or duplex stainless steel instead. - Do I need post-weld heat treatment for GB 0Cr18Ni10Ti?

لا-استقرار التيتانيوم binds carbon, preventing intergranular corrosion. This skips the need for post-weld annealing, unlike SUS304 (which requires heat treatment after welding for corrosive projects). - Is GB 0Cr18Ni10Ti safe for food contact?

Yes—it meets global food safety standards (على سبيل المثال, China’s GB 4806.9). Its non-toxic composition and resistance to high temperatures make it ideal for baking ovens and food sterilizers.