If you’re in construction, السيارات, or pipeline industries, electric welded ERW round steel هو فعال من حيث التكلفة, reliable material for countless projects. ERW (Electric Resistance Welding) creates strong, seamless-looking round steel that balances performance and affordability. This guide breaks down its welding technology, production process, properties, and uses—helping you choose the right ERW round steel for your needs.

1. Electric Welding Technology: The Backbone of ERW Round Steel

ERW round steel relies onresistance welding—a technique that uses electrical current to heat and fuse metal, no filler material needed. Here’s how it differs from other welding methods and why it’s ideal for round steel:

Key Welding Technologies Compared

| Welding Type | كيف تعمل | الأفضل ل | Advantage for ERW Round Steel |

|---|---|---|---|

| Resistance Welding (ERW) | Electric current passes through metal, heating it to fusion temperature; pressure fuses the seam | Round steel tubes/bars, mass production | سريع (حتى 100 pieces/min), no filler metal |

| Arc Welding | Electric arc melts metal and filler material | Thick steel structures, repairs | Slow for round steel; leaves weld beads |

| Laser Welding | High-energy laser melts metal for precise joins | رفيع, أجزاء عالية الدقة | Expensive; overkill for standard round steel |

Critical ERW Welding Parameters

To ensure strong welds, manufacturers control these key settings:

- Welding Current: 500–2,000 A (higher for thicker steel to ensure full fusion).

- Welding Voltage: 10–30 V (matches current to steel thickness).

- Welding Speed: 1–5 m/min (balances speed and weld quality—too fast causes weak seams).

Safety Note: ERW welding uses high currents, so workers need insulated gloves and eye protection. Modern mills usewelding automation to reduce human error and improve safety.

2. Steel Production Processes: From Iron Ore to ERW Round Steel

ERW round steel goes through a multi-step production process to ensure strength and consistency. Here’s the full workflow:

- Iron Ore Processing: Iron ore is crushed and mixed with coke to create iron in a blast furnace.

- Steelmaking: The iron is refined in a basic oxygen steelmaking (BOS) أو electric arc furnace (EAF) to remove impurities and adjust carbon content.

- Continuous Casting: Molten steel is cast into billets (round/square metal bars) via continuous casting—these are the raw material for ERW round steel.

- Hot Rolling: Billets are heated to 1,100–1,200°C and rolled into long, cylindrical shapes (preliminary round steel).

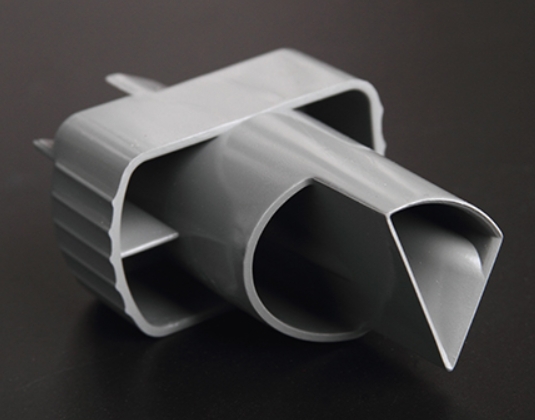

- ERW Welding: For tubes (a common ERW round steel form), flat steel strips are bent into a circle, ثم ERW welding fuses the seam to create a tube. For solid round bars, ERW may join smaller sections (less common for solid steel).

- الصلب: The welded round steel is heated to 600–700°C and cooled slowly to reduce stress from welding and rolling.

- الانتهاء: Steps like pickling (removes scale), galvanizing (adds rust resistance), أو straightening ensure the final product meets specs.

- قطع: The steel is cut to standard lengths (على سبيل المثال, 6ft, 12ft) or custom sizes for delivery.

3. ERW (Electric Resistance Welding): المزايا, Disadvantages & ضبط الجودة

ERW welding is popular for round steel, but it has pros and cons to consider. Strict quality control is key to avoiding defects.

ERW Welding Advantages

- فعالة من حيث التكلفة: No filler material needed; fast production reduces labor costs (20–30% cheaper than seamless steel).

- High Speed: Mills can produce up to 1,000 meters of ERW round steel per hour—ideal for large projects.

- Consistent Welds: Welding automation ensures uniform seam quality, reducing defects.

ERW Welding Disadvantages

- Seam Sensitivity: The welded seam is a potential weak point if not inspected—can fail under extreme pressure.

- Thickness Limits: Best for thin to medium thicknesses (1–20mm); thicker steel may need arc welding for stronger joins.

Quality Control for ERW Welding

To ensure strong, defect-free ERW round steel, manufacturers use these checks:

- Welding Inspection: Visual checks for seam cracks or uneven fusion; ultrasonic testing detects internal defects.

- Mechanical Testing: Tensile tests measure if the weld can withstand the same قوة الشد as the base steel.

- Chemical Analysis: Ensures the steel’s composition (على سبيل المثال, carbon content 0.15–0.25% for mild steel) meets standards.

مثال حقيقي: A pipeline company rejected a batch of ERW round steel tubes after ultrasonic testing found small cracks in the welds—this prevented a potential leak in a water pipeline.

4. Round Steel Characteristics: What Makes ERW Round Steel Useful?

ERW round steel has specific traits that make it suitable for various applications. Here’s a breakdown of its key characteristics:

الخصائص الميكانيكية (Mild Steel ERW Round Steel)

| ملكية | القيم النموذجية | Use Case Relevance |

|---|---|---|

| قوة الشد | 400–550 MPa | Supports structural loads (على سبيل المثال, building beams) |

| قوة العائد | 250-350 ميجا باسكال | Resists bending in automotive parts |

| استطالة | 20-30 ٪ | Ductile enough for bending (على سبيل المثال, furniture frames) |

| صلابة | 110–130 BHN | سهل الجهاز (على سبيل المثال, ثقوب الحفر) |

Dimensional & Surface Traits

- Dimensions: Outer diameter (OD) ranges from 5mm to 200mm; length up to 12m. تسامح is ±0.1mm for OD (good for precision parts).

- الانتهاء من السطح: Mill finish (سلس, minor scale) or galvanized (zinc-coated for rust resistance).

- مقاومة التآكل: Uncoated ERW round steel rusts easily—galvanizing extends outdoor life to 10+ سنين.

Weight Calculation

To estimate weight (critical for shipping), use this formula:

وزن (kg/m) = 0.00617 × OD (مم)²

مثال: A 10mm OD ERW round steel bar weighs ~0.617 kg/m.

5. Material Applications: Where ERW Round Steel Shines

ERW round steel’s affordability and strength make it a staple in these industries:

بناء

- Structural applications: ERW round steel bars reinforce concrete (على سبيل المثال, foundation pillars) and form support beams. A residential builder used 12mm ERW round steel for a house’s roof trusses—cost 25% less than seamless steel.

- Fencing: Galvanized ERW round steel posts resist rust, making them ideal for outdoor fences.

السيارات

- Mechanical components: ERW round steel tubes make up drive shafts and suspension parts—their consistent OD ensures a tight fit with bearings.

- أنظمة العادم: Heat-resistant ERW round steel tubes handle high temperatures in car exhausts.

Pipeline & Transportation

- Pipeline applications: ERW round steel tubes transport water, الغاز, and oil (for low-pressure lines—high-pressure lines use seamless steel).

- Trailer frames: ERW round steel bars form the structure of utility trailers—lightweight but strong enough to carry loads.

صناعي & Daily Use

- أثاث: ERW round steel tubes create chair frames and table legs (easy to bend into designs).

- Agricultural machinery: ERW round steel parts (على سبيل المثال, plow shafts) withstand dirt and impact in farm equipment.

6. Quality and Standards: Ensuring You Get High-Quality ERW Round Steel

To avoid defective ERW round steel, look for compliance with global standards:

المعايير الرئيسية

| المنظمة القياسية | Common Specs | استخدام الحالة |

|---|---|---|

| ASTM (نحن.) | ASTM A513 (ERW steel tubes), ASTM A615 (round bars) | قطع غيار السيارات, construction |

| ISO (عالمي) | ISO 8484 (ERW steel tubes) | Pipelines, structural steel |

| في (أوروبا) | في 10219 (ERW steel tubes) | Industrial machinery, أثاث |

| JIS (Japan) | JIS G3444 (ERW steel tubes) | Marine applications, السيارات |

Quality Assurance Tips

- Ask for a Mill Test Report (MTR) to confirm chemical composition and mechanical properties.

- تحقق من quality certification (على سبيل المثال, ISO 9001) to ensure the manufacturer follows strict quality management systems.

- Inspect the weld seam for cracks or unevenness—avoid steel with visible defects.

منظور Yigu Technology

في Yigu Technology, نوصيelectric welded ERW round steel for clients balancing cost and performance. We supply ERW round steel that meets ASTM and ISO standards, with galvanized options for outdoor use. لعملاء البناء, we offer custom-cut lengths to reduce waste—one client saved 15% by ordering 8ft bars instead of standard 12ft. Our quality checks include ultrasonic weld testing, ensuring the steel is strong enough for structural or automotive use.

التعليمات

- Is ERW round steel suitable for high-pressure pipelines?

No—ERW round steel’s welded seam is a weak point under high pressure (على سبيل المثال, oil pipelines). Use seamless steel for high-pressure applications; ERW works for low-pressure water/gas lines. - Can ERW round steel be painted or coated?

نعم! Clean the surface with a degreaser first, then apply paint, الايبوكسي, أو طلاء مسحوق. Galvanized ERW round steel can also be painted, but use a primer designed for zinc surfaces. - How does ERW round steel compare to seamless round steel in price?

ERW round steel is 20–30% cheaper than seamless steel. Seamless steel has no weld seam (stronger for high pressure), but ERW is better for budget-friendly, low-to-medium stress applications.