If you’ve been trying to decide between 3D printing and CNC machining for your next project, you’re not alone. These two manufacturing technologies each have their strengths, but 3D printing offers some unique advantages that make it the better choice for many applications. From complex geometries to faster turnaround times, additive manufacturing has transformed what’s possible in custom part production. في هذا الدليل, we’ll explore exactly why and when 3D printing outperforms CNC machining.

Design Freedom: Creating What Was Previously Impossible

One of the most significant advantages of 3D printing over CNC machining is the incredible design freedom it offers. This game-changing benefit stems from the fundamental difference in how these technologies work.

Complex Geometries Without Compromise

3D printing builds parts layer by layer, which means it can create shapes that would be impossible or extremely difficult with CNC machining’s subtractive approach. While CNC machines struggle with geometries they can’t reach with cutting tools, 3D printers excel at:

- Hollow structures with internal features: Creating lightweight parts with internal lattices or channels is straightforward with 3D printing but would require complex tool paths and significant waste with CNC machining.

- Organic shapes that follow natural contours: Medical implants, ergonomic designs, and nature-inspired structures are easily produced with 3D printing.

- Lattice structures for weight reduction: These strength-to-weight optimized designs are ideal for aerospace and automotive applications but are impractical to machine.

- Internal right angles: Unlike CNC machining, which creates rounded internal corners due to tool geometry, 3D printing can produce sharp internal angles without additional processes.

CNC machining’s limitations come from the need for tool access—if a cutting tool can’t reach a surface, that feature can’t be machined. This creates significant design constraints that 3D printing simply doesn’t have.

No Tool Access Restrictions

With CNC machining, your design must accommodate the physical limitations of cutting tools. Deep cavities, تقف, and complex internal features often require multiple setups, custom fixtures, or may be impossible altogether. 3D printing eliminates these restrictions because:

- Layers are built from the bottom up, allowing access to all areas of the part during production

- Support structures (when needed) can be easily removed post-printing

- Complexity doesn’t increase production difficulty or time

This freedom means engineers can focus on optimal part performance rather than manufacturability constraints.

Cost Efficiency for Low-Volume Production

When it comes to producing small quantities of parts, 3D printing often delivers significant cost advantages over CNC machining.

Lower Setup and Tooling Costs

CNC machining requires substantial setup time and custom tooling, especially for complex parts. Each new design may need:

- Custom fixtures to hold the material

- Specific cutting tools selected for the material and geometry

- Programmed tool paths optimized for the part

- Operator time for setup and calibration

These setup costs are fixed regardless of the number of parts produced, making CNC expensive for small runs. 3د الطباعة, by contrast, has minimal setup requirements:

- إعداد ملف CAD

- Selection of print parameters

- Material loading

This means the cost per part for 3D printing remains relatively stable even for single units, while CNC machining costs decrease significantly only when producing larger volumes.

Volume Cost Comparison

The cost advantage of 3D printing becomes clear when looking at different production volumes:

| حجم الإنتاج | 3D Printing Cost Efficiency | CNC Machining Cost Efficiency |

| 1-10 أجزاء | ممتاز (low setup costs) | فقير (high setup costs dominate) |

| 10-100 أجزاء | جيد (still cost-effective) | عدل (setup costs spread across more units) |

| 100-1000 أجزاء | عدل (material costs add up) | جيد (setup costs fully amortized) |

| 1000+ أجزاء | فقير (material costs high) | ممتاز (ideal volume for CNC) |

For prototyping or custom one-off parts, 3D printing typically costs 50-70% less than equivalent CNC machined parts. This makes it perfect for product development stages where multiple design iterations are needed.

Faster Turnaround Times

In today’s fast-paced manufacturing environment, speed to market can be a critical competitive advantage—and 3D printing delivers here as well.

Rapid Prototyping Capabilities

3D printing excels at producing parts quickly, with lead times that often surprise those used to traditional manufacturing:

- Desktop FDM printers can produce simple prototypes in as little as 1-3 أيام

- Industrial 3D printers can deliver functional parts in 24-48 ساعات

- Design changes can be implemented immediately without retooling

تصنيع CNC, by comparison, typically requires 1-2 weeks for prototype parts due to setup time, programming, and scheduling constraints. This speed advantage makes 3D printing invaluable during the product development cycle, where quick iteration can significantly shorten time to market.

سير العمل المبسط

The 3D printing workflow is inherently faster because it’s more automated and digital:

- CAD design is finalized

- File is prepared for printing (orientation, supports if needed)

- Print job is sent to the printer

- Part is built with minimal operator intervention

CNC machining involves more manual steps that add time:

- CAD design is finalized

- Toolpaths are programmed

- Material is secured in fixtures

- Tools are selected and loaded

- Machining process runs (with possible operator monitoring)

- Part is removed and repositioned if multiple setups are needed

These additional steps create bottlenecks that 3D printing avoids, especially for complex parts requiring multiple operations on a CNC machine.

Material Advantages for Specific Applications

While CNC machining offers a broader range of traditional materials, 3D printing provides unique material advantages for certain applications.

Specialized Materials for Unique Properties

3D printing has opened up possibilities with materials that are difficult or impossible to machine effectively:

- Flexible materials like TPU (thermoplastic polyurethane) can be easily 3D printed into complex flexible parts, while CNC machining flexible materials often results in deformation and poor surface finish.

- High-performance metal alloys such as Inconel, used in aerospace applications, can be 3D printed without the challenges of machining these extremely hard materials.

- Composite materials with unique properties, like carbon fiber-reinforced filaments, can be printed with directional strength properties optimized for specific loads.

- Biocompatible materials for medical applications can be precisely printed into custom implants that match patient anatomy.

These materials expand the range of functional parts that can be produced, from flexible living hinges to heat-resistant aerospace components.

Material Efficiency and Sustainability

3D printing is fundamentally more material-efficient than CNC machining:

- Additive manufacturing uses only the material needed for the part, typically generating less than 10% يضيع.

- تصنيع CNC removes material from a solid block, often wasting 50-90% of the original material, depending on part complexity.

- Unused 3D printing materials (like SLS powders) can often be recycled for future use.

This efficiency not only reduces material costs for 3D printing but also supports sustainability goals by minimizing waste. For expensive materials like titanium, this efficiency can result in significant cost savings even with higher per-unit material costs.

Superior Complexity-to-Cost Ratio

Perhaps the most revolutionary advantage of 3D printing is that complexity doesn’t increase cost—unlike with CNC machining.

Complexity Doesn’t Raise Production Costs

With CNC machining, every additional feature, curve, or internal structure adds to production time and cost. Each complex feature requires:

- More programming time

- Additional tool changes

- Longer machining cycles

- Possible multiple setups

في المقابل, 3D printing produces complex parts for the same basic cost as simple ones. Once the digital file is prepared, the printer builds the complexity automatically without additional labor or setup. This means you can incorporate:

- Integration of multiple parts into one assembly

- Topology-optimized designs for weight reduction

- Internal channels for fluid flow or heat management

- Custom lattice structures for strength optimization

All these features can be produced without increasing production costs, allowing engineers to prioritize performance over manufacturability.

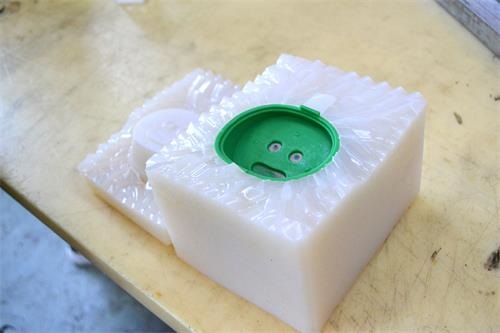

دراسة حالة: Plastic Enclosure Prototyping

Consider the example of prototyping a plastic electronics enclosure, which typically includes snap fits, living hinges, and interlocking features:

| عامل | تصنيع CNC | Desktop FDM 3D Printing |

| يكلف | Higher ($$) | Lower ($) |

| مهلة | 1-2 أسابيع | 1-3 أيام |

| مرونة التصميم | Limited by tool access | Full design freedom |

| Iteration Speed | بطيئة (requires reprogramming) | سريع (simply update CAD file) |

For this application, 3D printing delivers a better product faster and at lower cost—especially when multiple design iterations are needed.

Reduced Assembly Requirements

3D printing’s ability to create complex, integrated structures often reduces or eliminates the need for assembly, providing additional cost and time savings.

Consolidated Part Production

Instead of machining multiple components that must then be assembled, 3D printing can produce fully integrated parts in a single build. This offers several advantages:

- Eliminates assembly time and labor costs

- Reduces the risk of assembly errors

- Eliminates the need for fasteners or adhesives

- Improves overall part strength by removing potential failure points at joints

على سبيل المثال, a CNC-machined assembly with 10 components might require hours of machining time plus assembly, while a 3D printed version could be produced as a single part with no assembly required.

Simplified Supply Chains

By consolidating parts, 3D printing simplifies supply chains:

- Fewer unique components to track and inventory

- Reduced risk of supply chain disruptions for individual parts

- Lower shipping costs for fewer, more integrated components

- Easier maintenance with fewer parts to replace

This advantage becomes particularly valuable for complex assemblies like robotics, الأجهزة الطبية, and aerospace components.

Ideal for Rapid Prototyping and Iteration

Product development teams consistently choose 3D printing over CNC machining for prototyping, and for good reason.

Quick Design Iterations

في تطوير المنتج, the ability to quickly test and refine designs can make or break a project. 3D printing supports this process by:

- Allowing design changes to be implemented in hours rather than days

- Enabling multiple design variations to be tested simultaneously

- Reducing the cost of each iteration, encouraging more testing

تصنيع CNC, with its higher setup costs and longer lead times, creates barriers to frequent iteration. Designers may hesitate to test alternative approaches due to the time and expense involved.

Functional Prototypes That Match Final Parts

Modern 3D printing materials closely mimic the properties of production materials, allowing for:

- Functional testing of prototypes under real-world conditions

- Validation of form, ملائم, and function before committing to production tooling

- Early identification of design flaws that might not appear in non-functional prototypes

While CNC machined prototypes can also be functional, the higher cost often leads teams to produce fewer prototypes or skip certain tests—risks that 3D printing helps mitigate.

منظور Yigu Technology

“Yigu Technology recognizes 3D printing’s transformative advantages in design freedom, التكرار السريع, and cost-efficient low-volume production. We leverage its strengths for complex geometries and quick prototypes while combining with CNC for precision where needed. This hybrid approach delivers optimal solutions, using 3D printing to push design boundaries without sacrificing performance or cost-effectiveness.”

الأسئلة المتداولة

Is 3D printing always cheaper than CNC machining?

لا, but it’s typically cheaper for low volumes (1-100 أجزاء) والهندسة المعقدة. CNC machining becomes more cost-effective for higher volumes (100+ أجزاء) where setup costs are spread across more units.

Can 3D printed parts match the strength of CNC machined parts?

While 3D printed parts often have anisotropic strength (direction-dependent), advanced processes like SLS for plastics and DMLS for metals can produce parts with strength approaching CNC machined components, especially for functional prototypes and many end-use applications.

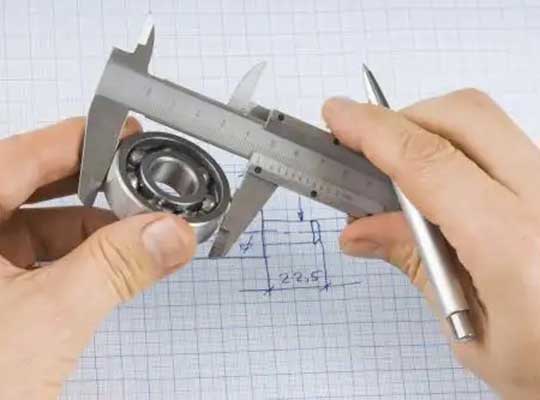

When should I still choose CNC machining over 3D printing?

Choose CNC machining for high-volume production, parts requiring extremely tight tolerances or superior surface finish, and when working with materials not well-suited for 3D printing or requiring the full mechanical properties of solid stock material.

Understanding these advantages helps teams make informed manufacturing decisions that balance cost, سرعة, and performance. While 3D printing isn’t the solution for every application, its unique benefits make it an essential tool in modern manufacturing.