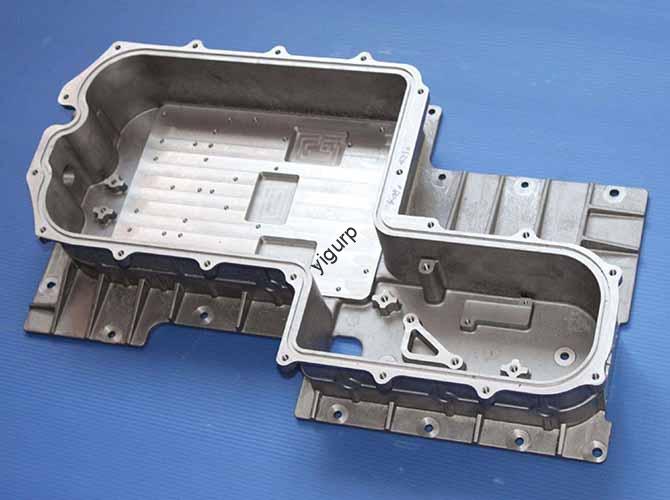

Our Aluminum Die Casting Services

At Yigu Technology, our Aluminum Die Casting solutions redefine what’s possible for high-performance manufacturing. Combining high precision engineering, advanced equipment, and decades of technical expertise, we transform lightweight, corrosion-resistant aluminum alloys into durable components for automotive, aerospace, and electronics industries. Whether you need large volume production or custom-designed parts, we deliver cost-effective, reliable results—backed by rigorous quality control and dedicated customer support.

What Is Aluminum Die Casting?

Aluminum Die Casting is a specialized metal casting process that uses high pressure to force molten aluminum (or aluminum alloys) into a steel mold (die), creating complex, dimensionally accurate parts. As a core casting technology, it leverages the unique properties of aluminum—lightweight, strength, and recyclability—to meet diverse industry needs.

A clear process overview reveals its efficiency: Molten aluminum (heated to 650–750°C) undergoes metal injection into a closed die at pressures ranging from 50–150 MPa. The metal cools and solidifies quickly, then the die opens to eject the finished part. Table 1 compares aluminum die casting to other die casting process types:

| Die Casting Type | Metal Used | Key Benefit | Ideal Use Case |

| Aluminum Die Casting | Aluminum Alloys | Lightweight + high strength | Automotive structural parts, aerospace components |

| Zinc Die Casting | Zinc Alloys | Low cost, small part precision | Electronics housings, hardware |

| Magnesium Die Casting | Magnesium Alloys | Ultra-light, high thermal conductivity | Laptop frames, drone parts |

Yigu Technology’s Aluminum Die Casting Capabilities

Our Aluminum Die Casting capabilities are built to handle the most demanding projects, from simple components to complex, custom designs.

Key Capabilities Breakdown

| Capability Area | Details |

| Large Volume Production | 100,000–800,000 units/month (scalable for automotive/electronics clients) |

| High Precision | Achieves tolerances as tight as ±0.05mm for critical features |

| Custom Solutions | Tailored mold design, alloy selection, and surface treatment for unique needs |

| Advanced Equipment | 25+ automated die casting machines (150–1,200 tons clamping force) |

| Quality Control | ISO 9001 & IATF 16949 certified; 100% dimensional inspection + X-ray porosity testing |

| Project Management | Dedicated teams to oversee timelines, costs, and compliance |

The Aluminum Die Casting Process

The die casting process for aluminum follows a structured workflow optimized for efficiency and precision, with each step tailored to maximize part quality.

- Mold Preparation: The steel die is preheated (150–250°C) and coated with lubricant to prevent metal sticking and ensure smooth ejection.

- Metal Injection: Molten aluminum alloy is injected into the die cavity at high speed (2–8 m/s) and pressure (50–150 MPa), ensuring full filling of complex geometries.

- Cooling & Solidification: The metal cools rapidly (10–30 seconds) in the die, maintaining dimensional accuracy while pressure is held to reduce porosity.

- Ejection: The die opens, and ejector pins push the finished part out. Excess material (flash) is removed via trimming.

- Post-Processing: Parts undergo quality inspection (dimensional checks, surface testing) and optional secondary operations (machining, surface treatment).

On average, the total cycle time for a medium-sized aluminum part (e.g., an automotive sensor housing) ranges from 20–40 seconds.

Materials Used in Aluminum Die Casting

Choosing the right aluminum alloys is critical for part performance, and we offer expert alloy selection support to match your project’s needs.

Aluminum Alloy Properties & Applications

| Alloy Type | Common Grades | Key Material Properties | Typical Applications |

| High Strength Alloys | A356, 6061 | Tensile strength (250–400 MPa), corrosion resistance | Automotive engine parts, aerospace brackets |

| General-Purpose Alloys | A380, ADC12 | Good castability, cost-effective | Electronics housings, consumer goods |

| Custom Alloys | Blended to specs | Tailored for heat resistance, conductivity, or wear | Industrial valves, medical devices |

All our casting materials undergo rigorous material testing (tensile strength, corrosion resistance) to ensure compliance with industry standards.

Surface Treatment for Aluminum Die Cast Components

Surface treatment enhances the durability, aesthetics, and functionality of aluminum die cast parts, addressing industry-specific challenges like corrosion and wear.

| Treatment Method | Purpose | Advantages | Ideal For |

| Anodizing | Creates a hard, protective oxide layer | Scratch-resistant, customizable colors (clear, black, gold) | Automotive exterior parts, aerospace components |

| Powder Coating | Applies a durable polymer finish | Chip-resistant, UV-stable, wide color range | Outdoor equipment, industrial machinery |

| Painting | Enhances aesthetics and basic protection | Fast application, low cost, matte/glossy finishes | Consumer electronics, lighting fixtures |

| Plating | Adds a metal layer (e.g., nickel, chrome) | Improves conductivity, decorative appeal | Electrical connectors, medical devices |

| Polishing | Creates a smooth, reflective surface | High-end appearance, hides minor defects | Luxury goods, architectural components |

| Texturing | Adds a non-slip or matte surface | Improves grip, reduces visible fingerprints | Tool handles, automotive interior parts |

Tolerances in Aluminum Die Casting

Tolerances and dimensional accuracy are hallmarks of our aluminum die casting process, with tight tolerances achievable through precision mold design and advanced measurement techniques.

Typical Tolerance Ranges

| Part Feature | Standard Tolerance | Tight Tolerance (Custom) | Tolerance Standards |

| Part Dimensions (≤100mm) | ±0.1mm | ±0.05mm | ISO 8062:2018 Class CT6 |

| Hole Positioning | ±0.15mm | ±0.08mm | DIN EN 13920 |

| Flatness | 0.1mm/m | 0.06mm/m | IATF 16949 |

These casting precision levels are verified using coordinate measuring machines (CMMs) and laser scanners, while machining tolerances are refined via CNC machining for critical features.

Advantages of Aluminum Die Casting

The advantages of Aluminum Die Casting make it the top choice for industries prioritizing performance, cost, and sustainability.

- Lightweight: Aluminum parts are 30–50% lighter than steel, improving fuel efficiency in vehicles and portability in electronics.

- High Strength: High strength alloys (e.g., A356) deliver tensile strength up to 400 MPa, suitable for structural applications.

- Cost-Effective: Automated production and minimal waste reduce per-unit costs by 15–25% compared to other precision manufacturing methods.

- High Production Rate: Short cycle times (20–40 seconds) enable large volume production for high-demand industries.

- Design Flexibility: Complex geometries (thin walls, intricate details) can be achieved without secondary operations.

- Corrosion Resistance: Natural oxide layer + optional surface treatments protect parts from harsh environments.

- Recyclability: Aluminum is 100% recyclable, reducing environmental impact and material costs.

Energy Efficiency: Casting aluminum requires 95% less energy than producing primary aluminum from ore.

Industry Applications of Aluminum Die Casting

Aluminum Die Casting serves diverse applications across industries that demand strength, light weight, and precision.

| Industry | Key Applications | Alloy of Choice | Why Aluminum Die Casting? |

| Automotive Industry | Engine blocks, transmission housings, EV battery frames | A356, ADC12 | Lightweight, high strength, cost-effective |

| Aerospace | Structural brackets, fuel system components, satellite parts | 6061, A356 | Precision, corrosion resistance, low weight |

| Electronics | Heat sinks, 5G base station parts, laptop frames | A380, AZ91D (magnesium-aluminum blend) | Thermal conductivity, dimensional stability |

| Consumer Goods | Power tool housings, kitchen appliance parts, furniture hardware | A380 | Durable, aesthetic finish, low cost |

| Medical Devices | Surgical instrument housings, diagnostic equipment frames | 6061, A356 | Biocompatibility, precision |

| Construction | Lighting fixtures, window frames, structural brackets | A380, 6063 | Corrosion resistance, strength |

Manufacturing Techniques for Aluminum Die Casting

Our manufacturing techniques combine innovation and proven practices to deliver consistent, high-quality aluminum die cast parts.

- Tooling: We use H13 hot-work steel for dies, engineered to withstand high temperatures and repeated use (100,000+ cycles). Mold cooling channels are optimized to reduce cycle time and prevent warping.

- Automation: Robotic arms handle metal injection, part ejection, and trimming, reducing human error and increasing production speed by 30–40%.

- Precision Machining: Secondary operations (CNC milling, drilling, threading) refine parts to meet tight tolerances for critical features.

- Rapid Prototyping: 3D-printed molds enable fast iteration of custom designs, reducing lead times for prototype development from weeks to days.

- Process Optimization: AI-powered sensors monitor temperature, pressure, and cycle time in real time, adjusting parameters to minimize defects.

Quality Assurance: Every part undergoes multi-stage testing (dimensional, porosity, surface finish) to ensure compliance with client specs.

Case Studies: Yigu Technology’s Aluminum Die Casting Success Stories

Our case studies demonstrate how we solve complex challenges for clients using aluminum die casting.

Case Study 1: Automotive EV Battery Frame

- Challenge: A leading EV manufacturer needed 100,000 lightweight battery frames monthly, with tight tolerances (±0.08mm) and corrosion resistance for outdoor use.

- Solution: Used A356 aluminum alloy with anodizing surface treatment. Implemented automated mold design and real-time pressure monitoring.

- Result: Frames were 40% lighter than steel alternatives, achieved 99.8% defect-free rate, and met IATF 16949 standards. Production time reduced by 20% vs. client’s previous supplier.

Case Study 2: Aerospace Structural Bracket

- Challenge: An aerospace client required high-precision brackets with tensile strength ≥350 MPa and compliance with AS9100 standards.

- Solution: Utilized 6061 aluminum alloy and added powder coating for corrosion protection. Conducted X-ray testing to ensure <1% porosity.

Result: Brackets met all AS9100 requirements, weighed 25% less than titanium alternatives, and passed 10,000+ hours of stress testing.

Why Choose Yigu Technology for Aluminum Die Casting?

When you partner with us for Aluminum Die Casting, you gain a trusted collaborator dedicated to your success. Here’s why clients choose us:

- Expertise: Our team has 20+ years of experience in aluminum die casting, with specialized knowledge in alloy selection and process optimization.

- Quality: We adhere to the strictest industry standards (ISO 9001, IATF 16949, AS9100), ensuring every part meets or exceeds your expectations.

- Custom Solutions: We work closely with your team to design parts for manufacturability, tailoring alloy composition, mold design, and surface treatment to your unique needs.

- Reliability: We maintain 98% on-time delivery rates, thanks to our scalable large volume production capacity and proactive supply chain management.

- Customer Service: A dedicated account manager provides 24/7 support, from design consultation to post-delivery follow-up.

- Cost-Effective: Our automated processes and material efficiency reduce per-unit costs by 15–25% compared to competitors.

Commitment to Excellence: We invest 15% of annual revenue in R&D to develop new manufacturing techniques (e.g., AI process control) that improve quality and reduce lead times.